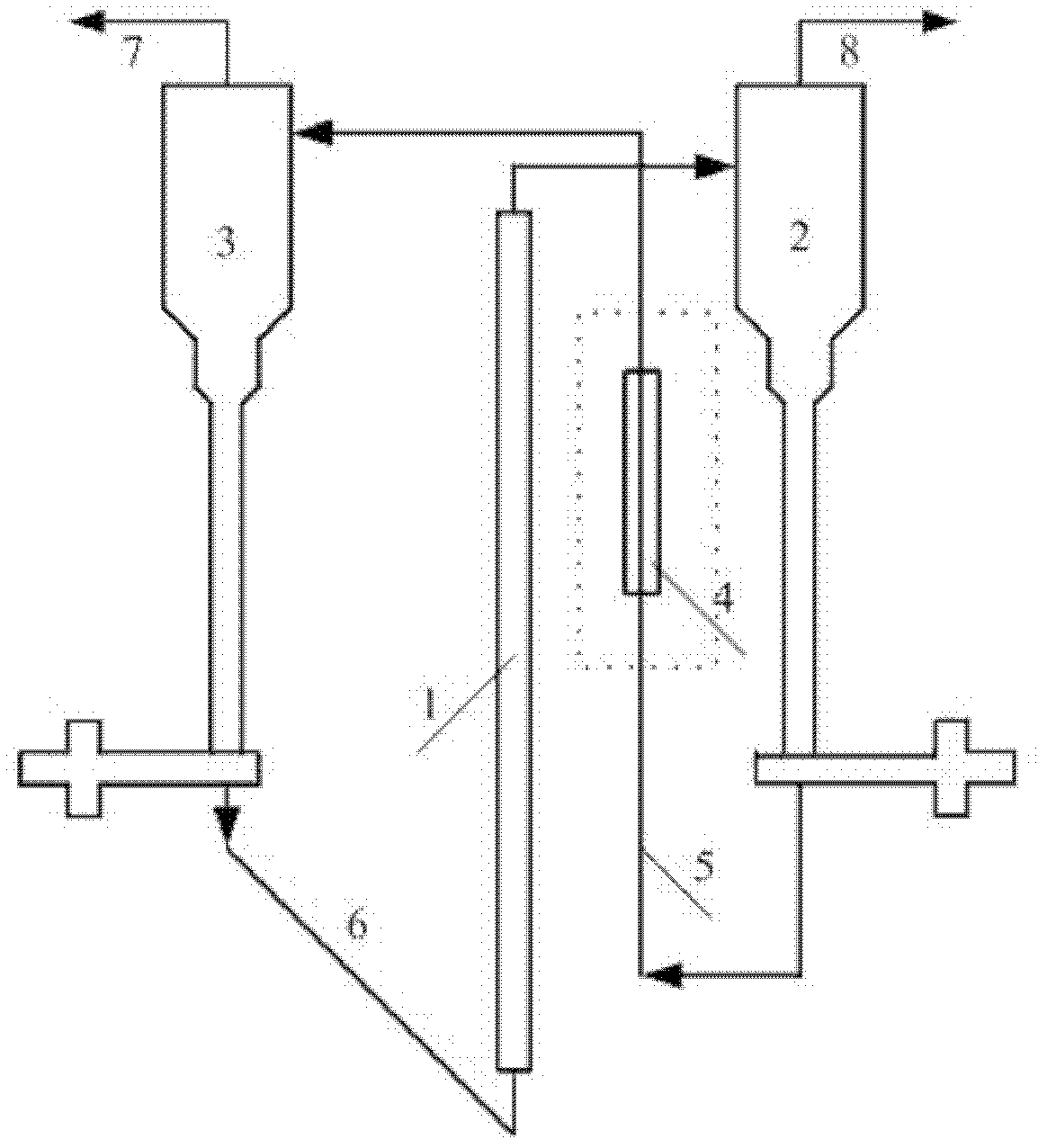

Method for monitoring catalyst circulation volume of catalytic cracking apparatus

A catalytic cracking unit and catalyst recycling technology, applied in catalytic cracking, cracking, hydrocarbon oil cracking, etc., can solve the problem that the catalyst circulation volume cannot meet the real-time requirements, the real-time performance cannot meet the advanced control of the riser, and the accuracy is difficult to be guaranteed, etc. problem, to achieve the effect of product distribution, promotion and easy transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

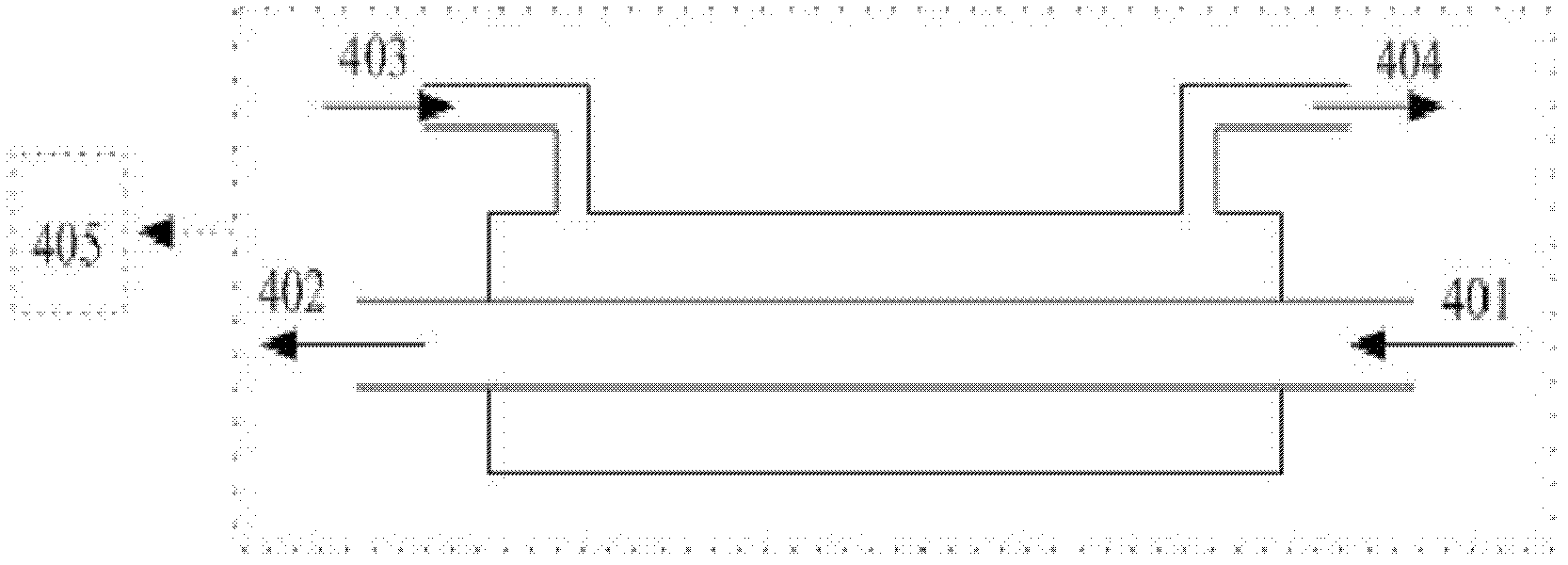

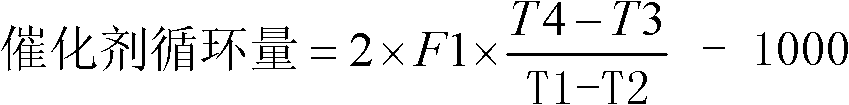

[0025] use figure 2 In the given processing unit, the pipe diameter ratio of the conveying medium pipe and the waiting catalyst conveying pipe is 4. According to the normal riser catalytic cracking reaction, the temperature of the inlet catalyst 401 is 438°C, and the temperature of the outlet catalyst 402 is 365°C. When the medium is air, the flow rate of the medium inlet 403 is 550 L / h, the temperature is 29°C, the temperature of the medium outlet 404 is 375°C, and the value of the control module 405 is 4.2kg / h.

Embodiment 2

[0027] use figure 2 In the given processing unit, the pipe diameter ratio of the conveying medium pipeline and the spent catalyst conveying pipeline is 10. According to the normal riser catalytic cracking reaction, the temperature of the inlet catalyst 401 is 432°C, and the temperature of the outlet catalyst 402 is 350°C. When the medium is nitrogen, the flow rate of the medium inlet 403 is 1300L / h, the temperature is 32°C, the temperature of the medium outlet 404 is 368°C, and the value of the control module 405 is 9.6kg / h.

Embodiment 3

[0029] use figure 2 In the given processing unit, the pipe diameter ratio of the conveying medium pipeline and the spent catalyst conveying pipeline is 20. According to the normal riser catalytic cracking reaction, the temperature of the inlet catalyst 401 is 425°C, and the temperature of the outlet catalyst 402 is 310°C. When the medium is water vapor, the flow rate of the medium inlet 403 is 3100L / h, the temperature is 110°C, the temperature of the medium outlet 404 is 355°C, and the value of the control module 405 is 12.2kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com