Solar semi-shielding type thermal drive automatic tracking device

An automatic tracking device, solar technology, applied in the field of solar tracking, can solve the problems of large tracking error, slowness, slow tracking speed, etc., and achieve the effect of high tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

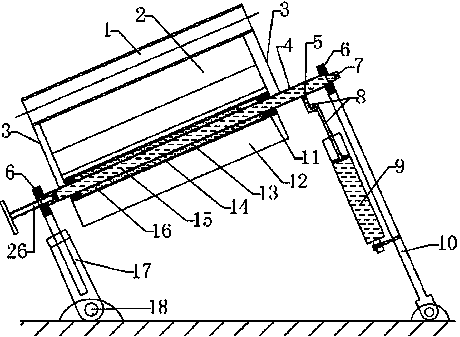

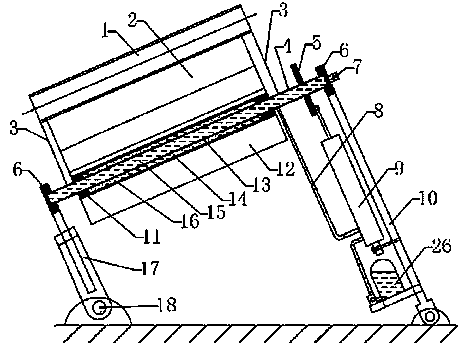

[0031] Such as figure 1 , Figure 4 , Figure 5 As shown, a first heat collecting tube 1 is provided on the focal line position of the first parabolic concentrating groove 2, an opening 19 is provided at the center of the first parabolic concentrating groove 2, and a second parabolic concentrating groove is provided at the opening 19. Groove 12 is provided with second heat collecting tube 14 at the focal line place of second parabolic concentrating groove 12, and the sunlight that shoots to second heat collecting tube 14 from the rear of second parabolic concentrating groove 12 and the side rear direction is first collected The heat pipe 1 and the second parabolic concentrating groove 12 are all blocked, and the sunlight that shoots to the second heat collecting tube 14 from the front and side front of the second parabolic concentrating groove 12 is focused on the second heat collecting tube 14, from the first collecting The sunlight that heat pipe 1 direction radiates to th...

Embodiment 2

[0037] Such as figure 1 , Figure 4 , Figure 5 As shown, on the basis of Embodiment 1, the rotating device 5 is changed into a hollow turntable, the connection mode between the two ends of the rotating shaft 4 and the second bracket 10 is changed into a sliding sleeve connection, and the second bracket 10 is changed into a fixed type at both ends. Yes, the bottom of the second bracket 10 is fixed on the foundation.

[0038] The first parabolic light-gathering groove 2 is placed east-west and rotates north-south. There are 12 first parabolic light-gathering grooves 2, and every 4 are connected in series to form a row, and a total of 3 rows form an array.

Embodiment 3

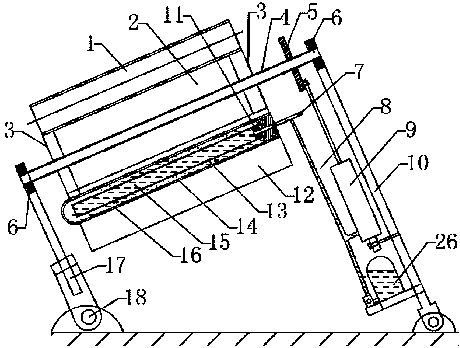

[0040] Such as figure 2 , Figure 4 , Figure 5 As shown, on the basis of Embodiment 1, the rotating device 5 and the pressure guiding tube 8 are changed into a split type, the rotating device 5 is a solid turntable, and a small hole is opened on the rotating shaft 4, and a guide The pressure hose communicates with the hydraulic cylinder.

[0041] The two ends of the rotating shaft 4 are connected to the second support 10 through the bearing 6. The second support 10 is fixed at one end and telescopic at the other end. The bottom of the second support 10 is fixed on the foundation. A temperature compensation adjustment device (26) is installed on the hydraulic cylinder (9), and the temperature compensation adjustment device (26) is a manual hydraulic pump.

[0042] The first parabolic light-gathering groove 2 is placed east-west and rotates north-south, and there is only one first parabolic light-gathering groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com