A navigation and positioning method for a substation inspection robot

An inspection robot, navigation and positioning technology, applied in two-dimensional position/channel control and other directions, can solve the problems of heavy ground processing workload, poor path flexibility and high cost, and achieve the effect of simple construction, high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

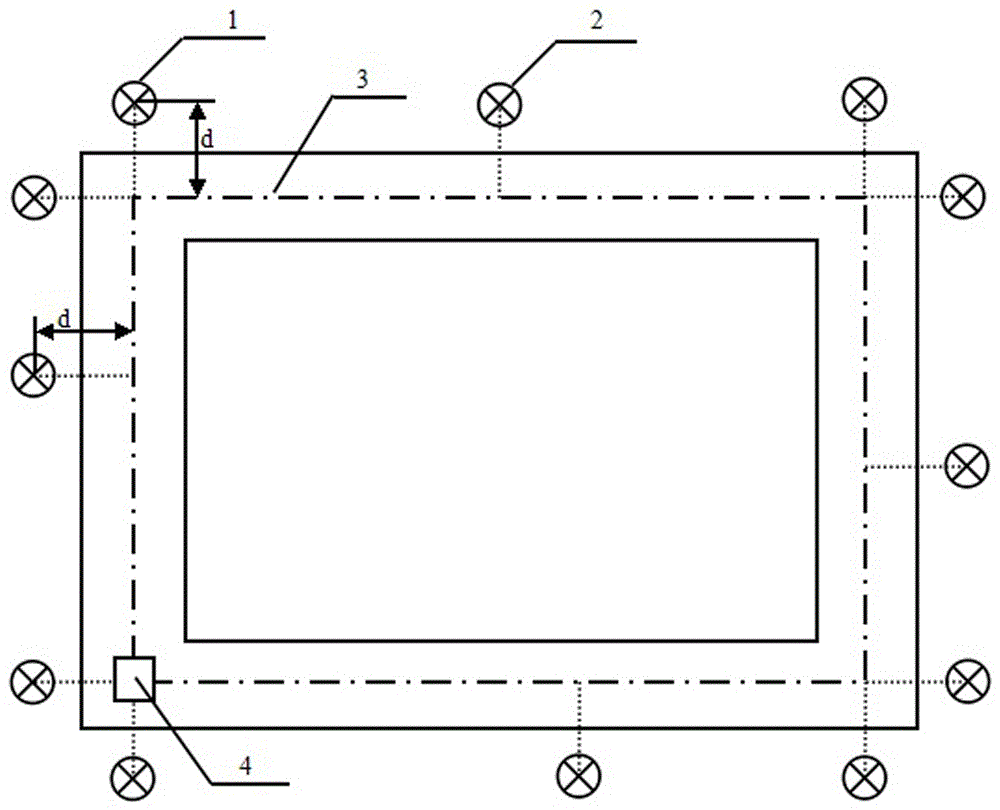

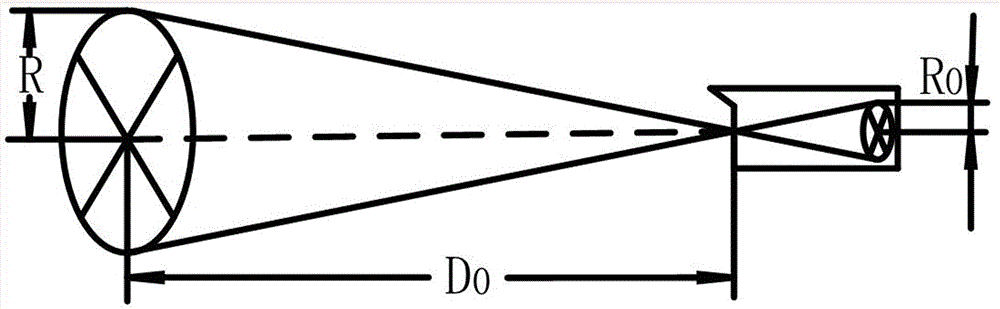

[0024] Implementation mode one: from figure 1 It can be seen that there are four groups of devices to be inspected in this embodiment, and the inspection trajectory of the robot is determined to be a rectangle according to their positions, as shown by the dotted line in the figure. Next, you need to install the tracking navigation light and the positioning navigation light. First, determine the installation location, and extend each side of the rectangular inspection track. The extension length can be set to d. The value of d ensures that when the robot reaches the end of the inspection track, it The imaging of the lamp in the infrared thermal imager preferably takes up 2 / 3 of the image. This position is the installation position of the tracking and navigation light 1. In this embodiment, eight tracking and navigation lights are installed. The position corresponding to each equipment to be inspected on the inspection track is a fixed point. In this embodiment, there are four f...

Embodiment approach 2

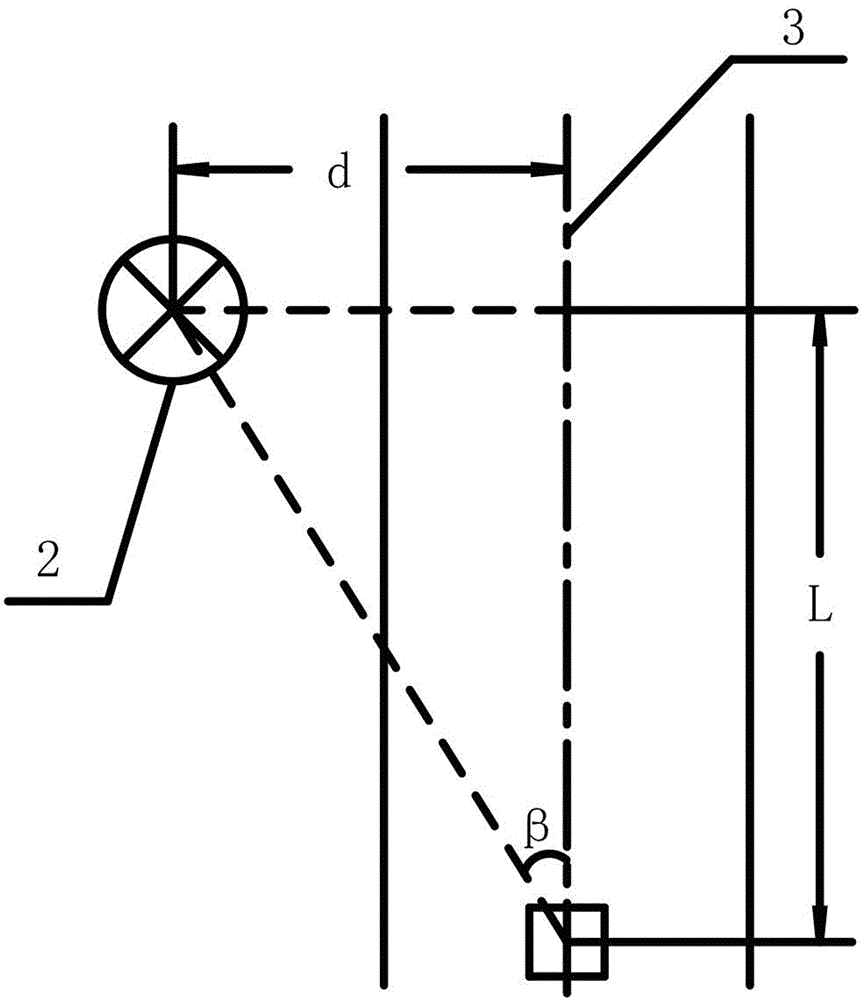

[0048] Embodiment 2: When there is a curved track in the path, the installation method of the tracking navigation light 1 and the positioning navigation light 2 is as follows: Figure 4 , the two straight trajectories transition through a curved trajectory. According to the starting point 4 and the moving direction of the robot marked in the figure, a tracking navigation light 1 is installed at a distance d on the extension line of the rear end of each straight trajectory. The distance d ensures that the tracking The track navigation light 1 is not on the moving track of the robot, and the imaging area of the infrared thermal imaging camera occupies more than 2 / 3 of the imaging area as far as possible. After determining the fixed-point position and quantity according to the equipment to be inspected, locate the distance d beside the straight track of the navigation light installation 0 place, such as Figure 4 As shown in , save the distance D between each fixed point and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com