Paclitaxel nanoparticles and preparation method thereof

A paclitaxel and nanoparticle technology, which is applied in the field of polymer nanoparticle preparation, can solve the problems of changing shape and particle size, increasing gastrointestinal irritation, and difficult storage, so as to reduce dosage, reduce toxic and side effects, and encapsulate high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

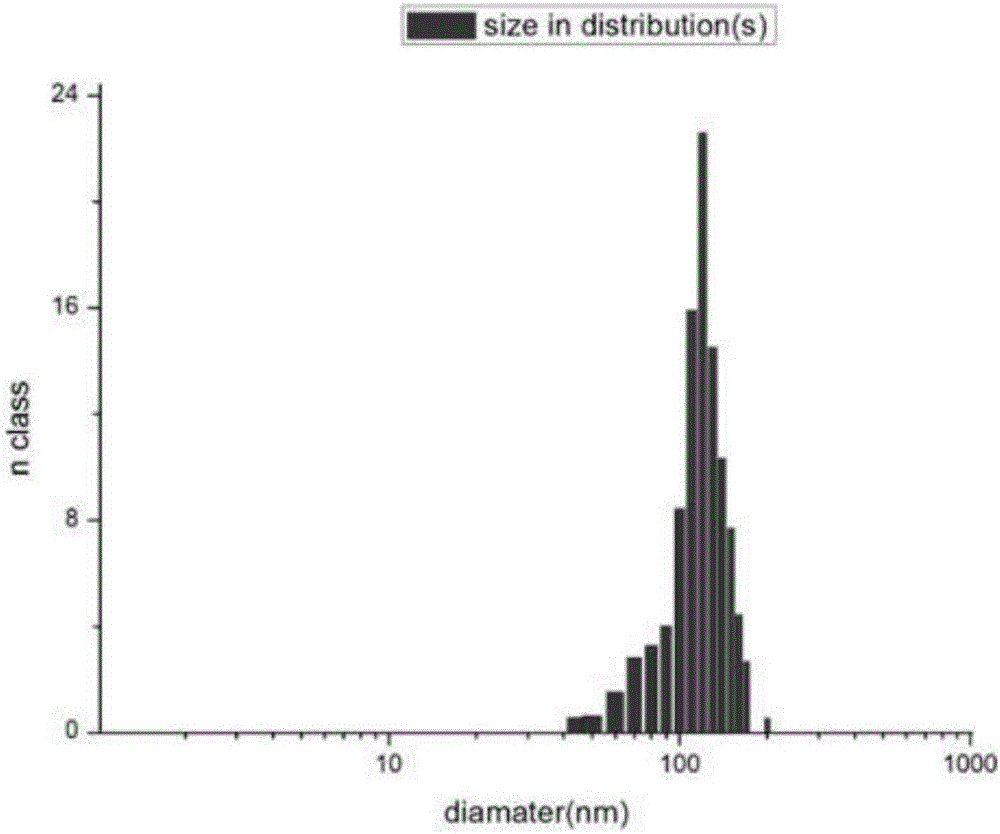

[0044] Embodiment 1: Optimization of preparation conditions of paclitaxel nanoparticles

[0045] 1. Investigation of preparation method

[0046] Nanoparticles can be prepared by rotary evaporation, dialysis and rotary evaporation dialysis. The rotary evaporation method is to drop the solution mixed with the drug and nanomaterials into water, and stir at a certain speed to obtain a micellar solution. In the dialysis method, the drug and nano-blocks are directly loaded into the dialysis bag, and the nano-micelle solution is obtained through dialysis. The rotary evaporation dialysis method is to combine the two, the rotary evaporation method is the same as the above, the solution obtained by the rotary evaporation is put into a dialysis bag, and dialyzed in water to obtain a micellar solution. The advantage of the rotary evaporation method is that the reaction is more thorough and purer nanoparticles are obtained.

[0047] The nanoparticles prepared by different methods were o...

Embodiment 2

[0069] Embodiment 2: Preparation of folate-free paclitaxel nanoparticles

[0070] Accurately weigh 300 mg of PEG-PLA polymer, dissolve in 1 ml of tetrahydrofuran, and prepare a 300 mg / ml organic solution. Weigh 50 mg of paclitaxel in the dark, dissolve it in 1 ml of dichloromethane, and prepare an organic solution with a concentration of 50 mg / ml. Fully mix the two solutions to make a uniform solution, add 3ml polyvinyl alcohol to the mixed solution, 30-40W ultrasonic 10min, make the drug polymer solution fully mixed, mix the organic solution with 20-30 drops / Add dropwise to 30ml ultrapure water at a speed of 1 minute, and ultrasonicate for 20 minutes at 300W in an ice bath. The obtained emulsion was stirred in a water bath at normal temperature and pressure for 4 hours, the organic solvent was volatilized, centrifuged (14000r / min) for 30 minutes, the precipitate was collected, washed 4 times with distilled water, and rehydrated. Put the rehydrated micellar solution into a ...

Embodiment 3

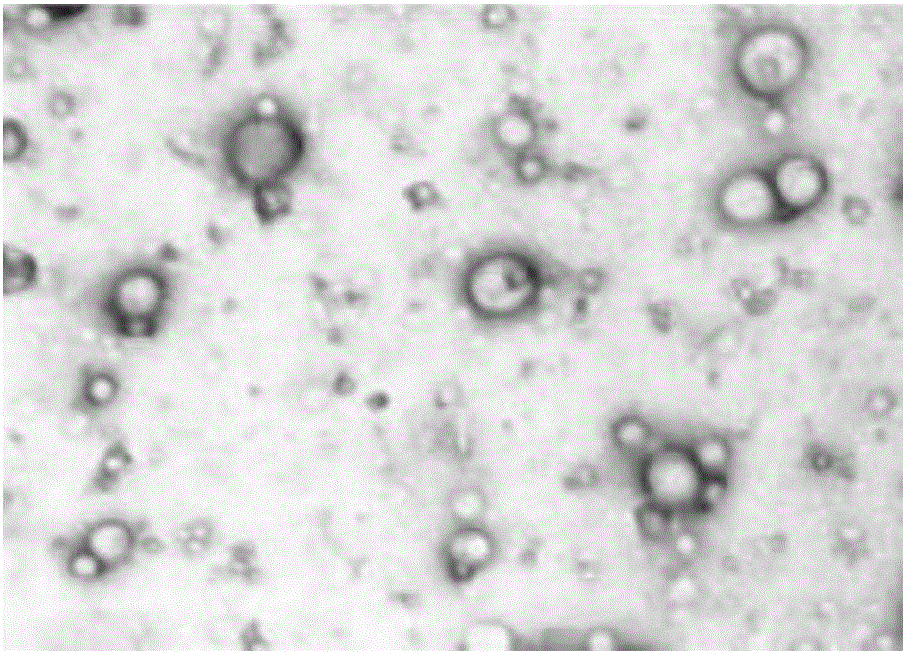

[0072] Embodiment 3: Preparation of paclitaxel folate nanoparticles

[0073] Weigh 270mg of polymer PEG-PLA, weigh 30mg of polymer polate-PEG-PLA, make the polymer with folic acid account for 10% of the total polymer, dissolve in 1ml tetrahydrofuran, and prepare an organic solution of 300mg / ml. Weigh 50 mg of paclitaxel in the dark, dissolve it in 1 ml of dichloromethane, and prepare an organic solution with a concentration of 50 mg / ml. Fully mix the two solutions to make a uniform solution, add 3ml polyvinyl alcohol to the mixed solution, 30-40W ultrasonic 10min, make the drug polymer solution fully mixed, mix the organic solution with 20-30 drops / Add dropwise to 30ml ultrapure water at a speed of 1 minute, and ultrasonicate for 20 minutes at 300W in an ice bath. The obtained emulsion was stirred in a water bath at normal temperature and pressure for 4 hours, the organic solvent was volatilized, centrifuged (14000r / min) for 30 minutes, the precipitate was collected, washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com