Low-alloy, high-strength and high-toughness composite phase steel and heat treatment method thereof

A heat treatment method and low-alloy technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as not suitable for industrialized large-scale production, short holding time, etc., to ensure process stability and structure uniformity, and low cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

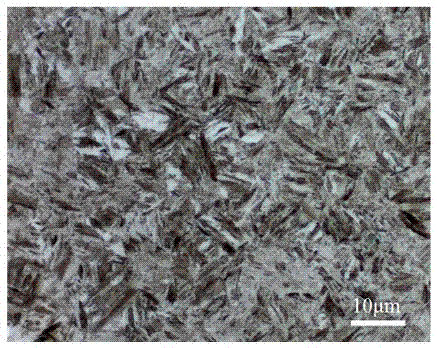

Image

Examples

Embodiment 1

[0052] The composition and weight percentage of the steel in the embodiment of the present invention are: C: 0.40%, Si: 0.90%, Mn: 1.80%, Cr: 2.3%, Al: 2.0%, S: 0.0015%, P: 0.0066%, and the rest For Fe.

[0053] The heat treatment steps are:

[0054] (1) Heat the steel at a rate of 15°C / s to the austenitization temperature of 900°C and hold it for 5 minutes to fully austenitize the workpiece;

[0055] (2) Then quench the workpiece to room temperature 20°C to obtain part of supersaturated martensite and austenite without martensitic transformation;

[0056] (3) Then fire at 300°C, and carry out carbon distribution isothermally for 5 minutes, so that the carbon is distributed from the martensite to the retained austenite, so that the retained austenite is rich in carbon and can be stable to room temperature;

[0057] (4) Finally, the workpiece is quenched to room temperature, and a multiphase steel with stable martensite and retained austenite is obtained at room temperature. ...

Embodiment 2

[0062] The composition and weight percentage of the steel in the embodiment of the present invention are: C: 0.49%, Si: 1.90%, Mn: 0.80%, Cr: 3.0%, Al: 4.9%, S: 0.0016%, P: 0.0075%, and the rest For Fe.

[0063] The heat treatment steps are:

[0064] (1) Heat the steel at a rate of 15°C / s to the austenitization temperature of 850°C and hold it for 5 minutes to fully austenitize the workpiece;

[0065] (2) Then quench the workpiece to room temperature 20°C to obtain part of supersaturated martensite and austenite without martensitic transformation;

[0066] (3) Then tempering at 350°C, and isothermal for 10 minutes for carbon distribution, so that the carbon is distributed from martensite to retained austenite, so that the retained austenite is rich in carbon and can be stable to room temperature;

[0067] (4) Finally, the workpiece is quenched to room temperature, and a multiphase steel with stable martensite and retained austenite is obtained at room temperature.

[0068] ...

Embodiment 3

[0070] The components and weight percentages of steel in the embodiment of the present invention are: C: 0.65%, Si: 1.20%, Mn: 2.0%, Cr: 4.0%, Al: 3.0%, S: 0.0015%, P: 0.0066% , and the rest is Fe.

[0071] The heat treatment steps are:

[0072] (1) Heat the steel at a rate of 15°C / s to the austenitization temperature of 900°C and hold it for 5 minutes to fully austenitize the workpiece;

[0073] (2) Then quench the workpiece to -20°C to obtain part of the supersaturated martensite and austenite without martensitic transformation;

[0074] (3) Then tempering at 300°C, and isothermal for 30 minutes for carbon distribution, so that carbon is distributed from martensite to retained austenite, so that the retained austenite is rich in carbon and can be stable to room temperature;

[0075] (4) Finally, the workpiece is quenched to room temperature, and a multiphase steel with stable martensite and retained austenite is obtained at room temperature.

[0076] After testing, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com