Pole piece cutting method

A cutting method and pole piece technology, applied in electrode manufacturing, electrode carrier/current collector, laser welding equipment, etc., can solve the problems of affecting battery performance, high maintenance and repair costs, unsuitable pole piece cutting, etc. quality, improve the battery qualification rate, and ensure the effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

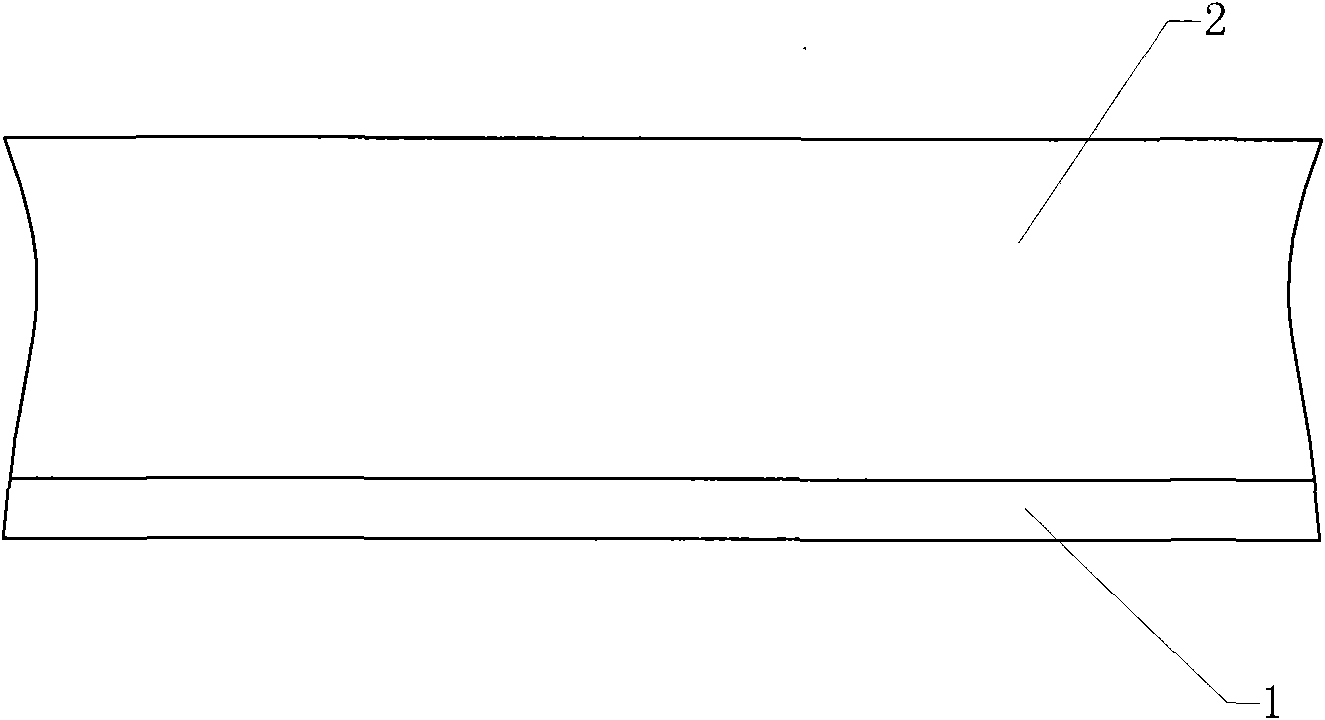

[0012] Uncut battery pole pieces such as figure 1 As shown, it includes a current collector 1 and a polar active material layer 2 coated on the upper and lower surfaces of the current collector 1 .

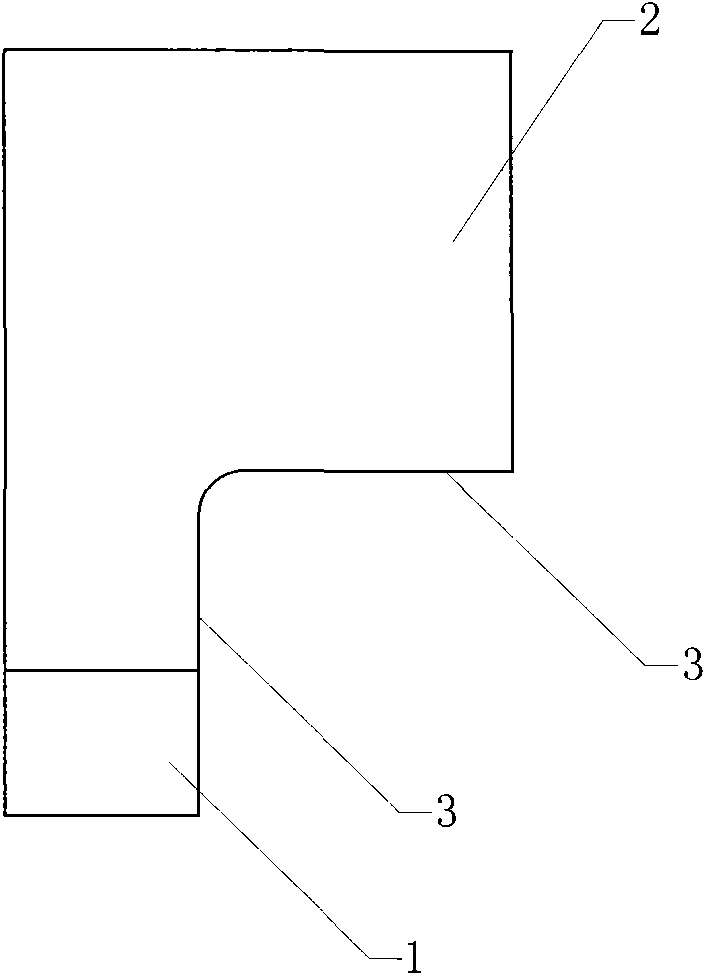

[0013] Using the battery pole piece cutting method of the present invention to figure 1 The pole piece of the battery shown is cut, the laser is placed a certain distance away from the pole piece, the focal length of the laser is adjusted to focus the laser on the cutting position on the pole piece, the driving mechanism drives the laser to run according to the predetermined trajectory, and the trajectory of the laser (that is, the laser The cutting route) is adapted to the shape of the pole piece cutting fracture 3, and the pole piece is fused by laser energy to obtain a pole piece fracture opening 3 of a predetermined shape. The trajectory of the laser operation is set according to the specific shape of the required pole piece cutting fracture, which can be a straight line, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com