Patents

Literature

50results about How to "Dissolve quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving anaerobic sludge granulation efficiency

ActiveCN107352647AImprove efficiencyIncrease speedWater treatment compoundsBiological treatment regulationSignalling moleculesChemistry

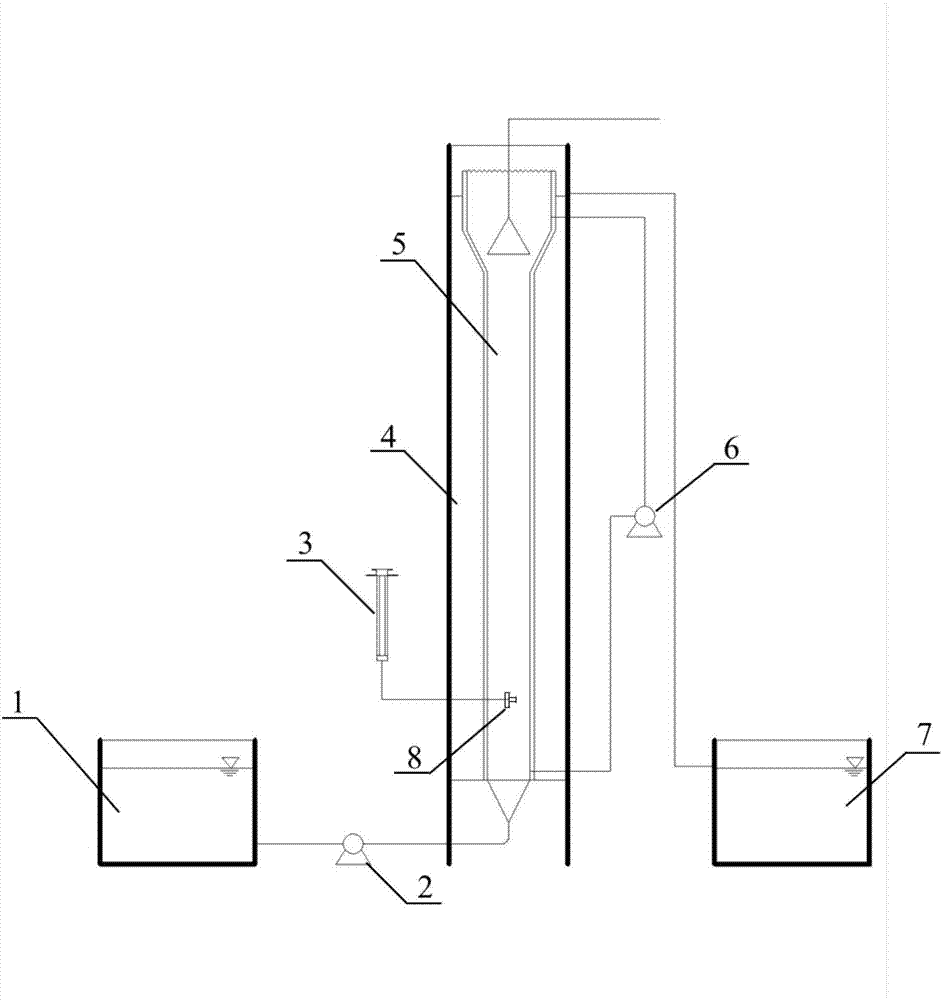

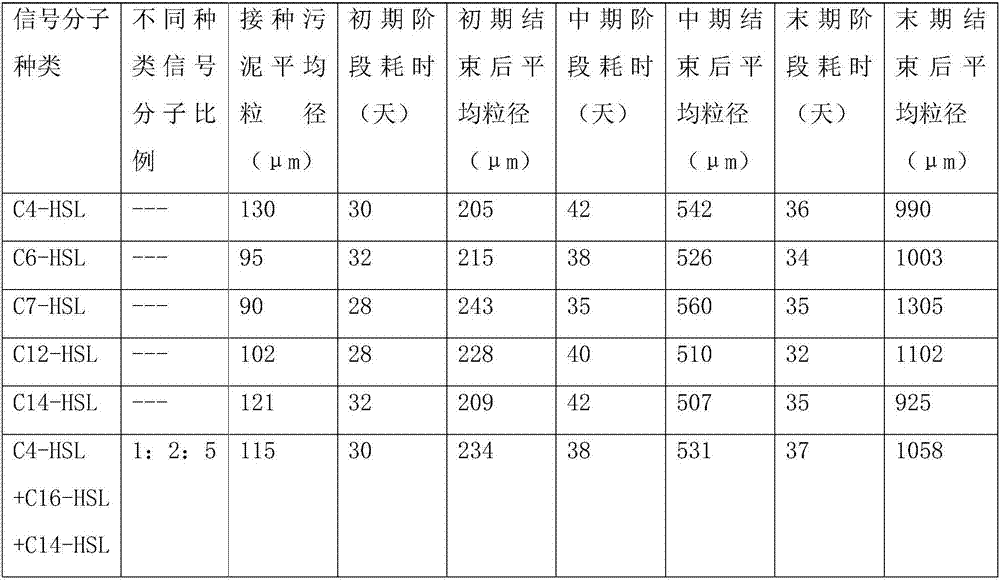

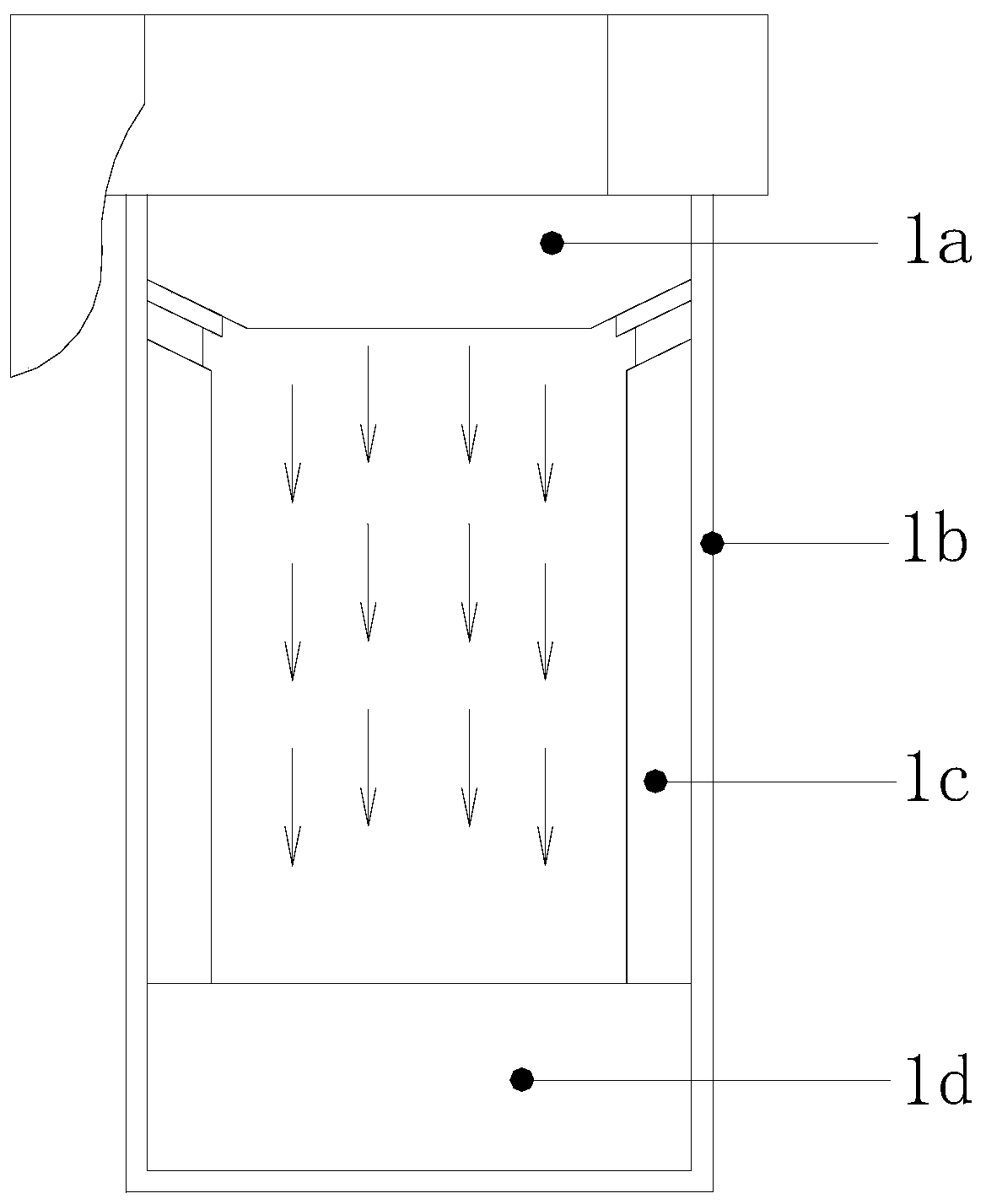

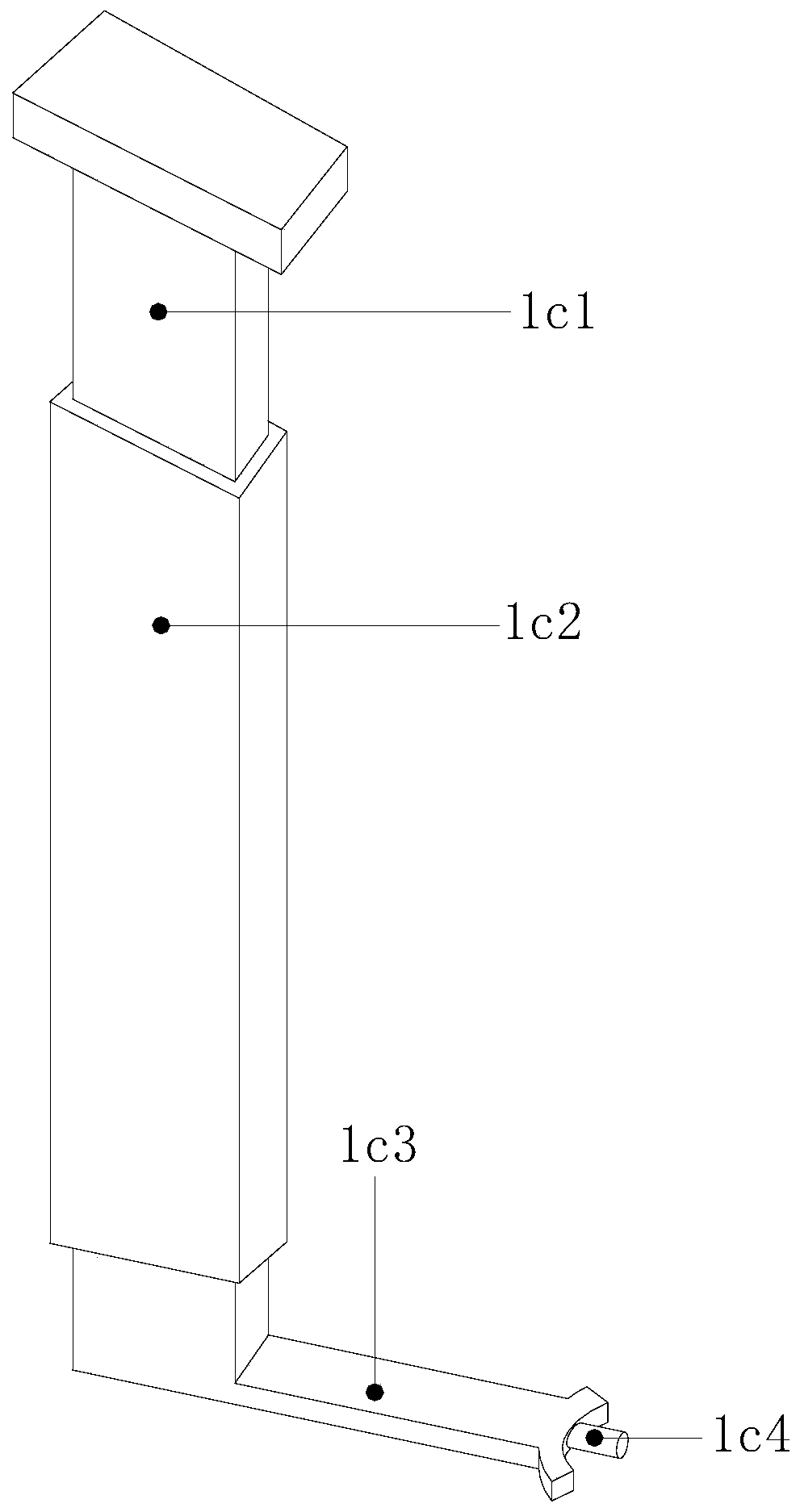

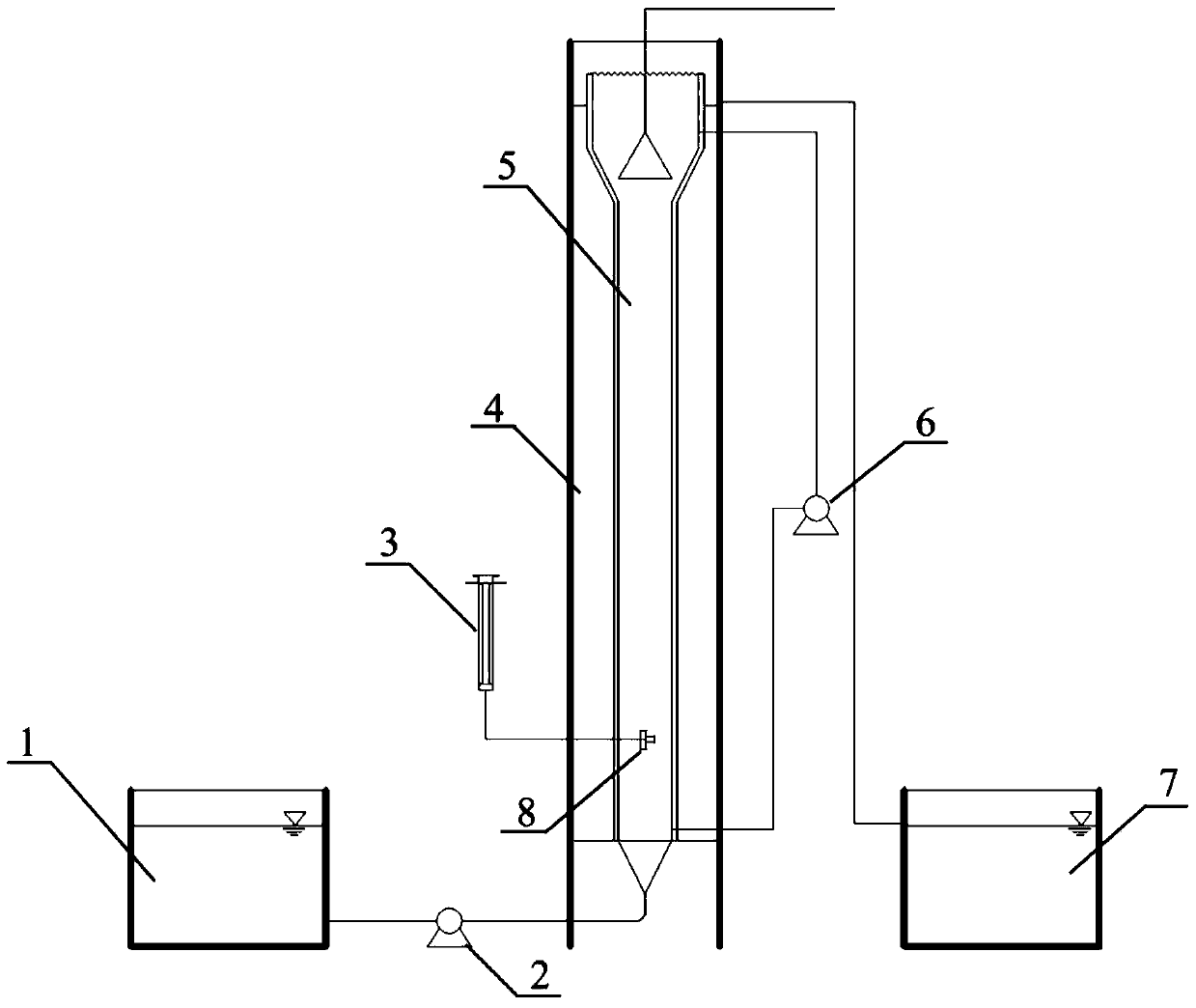

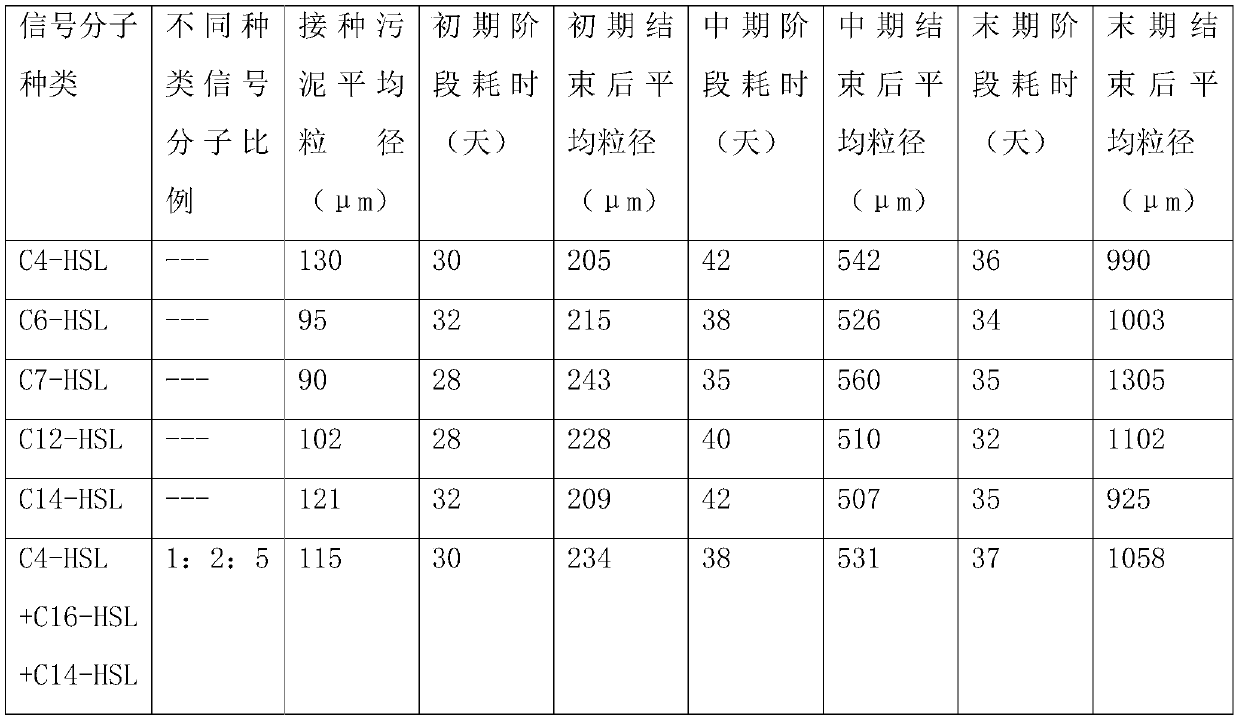

The invention discloses a method for improving the anaerobic sludge granulation efficiency, and belongs to the field of organic waste water treatment. The method for improving the anaerobic sludge granulation efficiency is provided for the problems that the anaerobic granular sludge culture circle is long, the granule stability is poor, and the culture cost is high in the prior art. The method comprises the steps that an appropriate number of organically synthesized acyl-homoserine lactone (AHL) signal molecules are added into the bottom of an EGSB reactor used for anaerobic sludge granulation culture periodically and mixed with anaerobic sludge, the addition cycle is the same as the hydraulic retention time, and the advantages that the anaerobic sludge granulation efficiency is high, the cost is low, the needed granulation time is greatly shortened, the formed granular sludge is good in stability, the structure is simple, and operation is convenient can be achieved.

Owner:NANJING UNIV

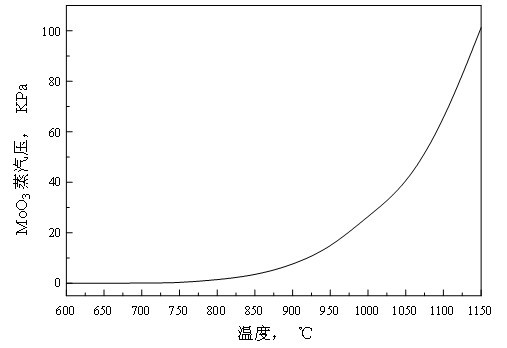

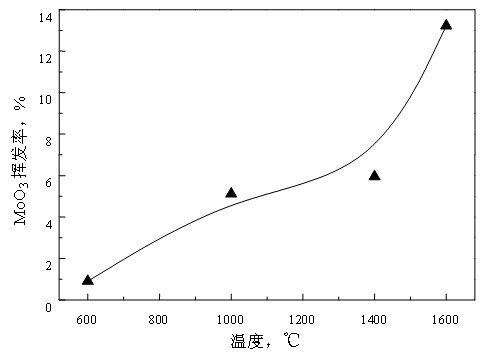

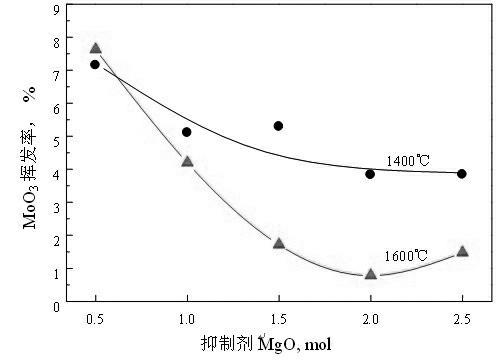

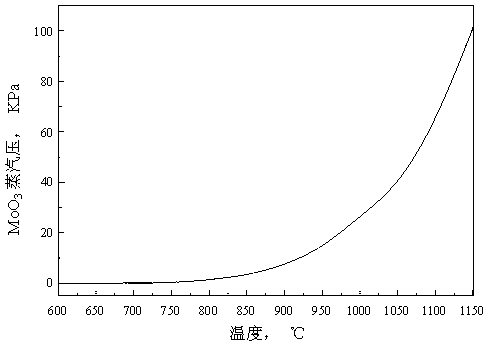

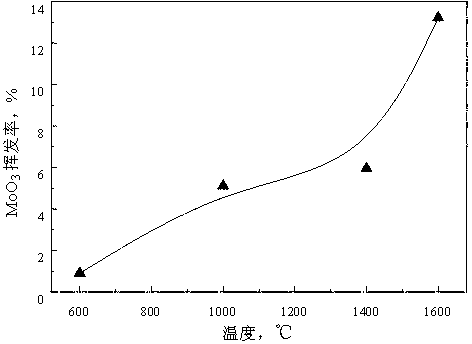

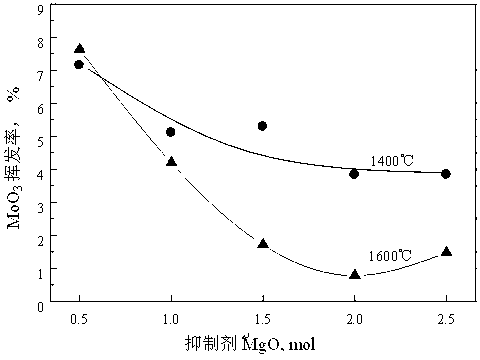

Manufacturing method of molybdenum or vanadium oxide briquetting for steelmaking alloying

The invention discloses a manufacturing method of molybdenum or vanadium oxide briquetting for steelmaking alloying, which comprises the following steps of: adding an inhibitor, a fluxing agent and a reducing agent into molybdenum or vanadium oxide; uniformly mixing the raw materials; wetting the mixture by a water-soluble adhesive; and pressing the wet mixture into a block, wherein the inhibitoris magnesia, the fluxing agent is fluorite and the reducing agent is ferrosilicon powder or carborundum powder. In the oxide briquetting, MgO contained in the magnesia is in tightly contact with MoO3or V2O5 to generate magnesium molybdate or vanadium molybdate difficult to volatilize by the solid-phase reaction, and the volatilization of MoO3 or V2O5 can be effectively inhibited; and meanwhile, the magnesia is difficult to hydrate and a water soluble compound (water glass, brine, urea-formaldehyde resin or the like) can be used as the adhesive. The method is simple and easy to operate, has high yield of directly alloying elements and can be popularized and applied in steel and iron works. Not only can the energy be greatly saved, the CO2 emission is reduced and the environmental load is reduced, but also the alloying cost of molten steel can be greatly reduced.

Owner:SHIJIAZHUANG IRON & STEEL +1

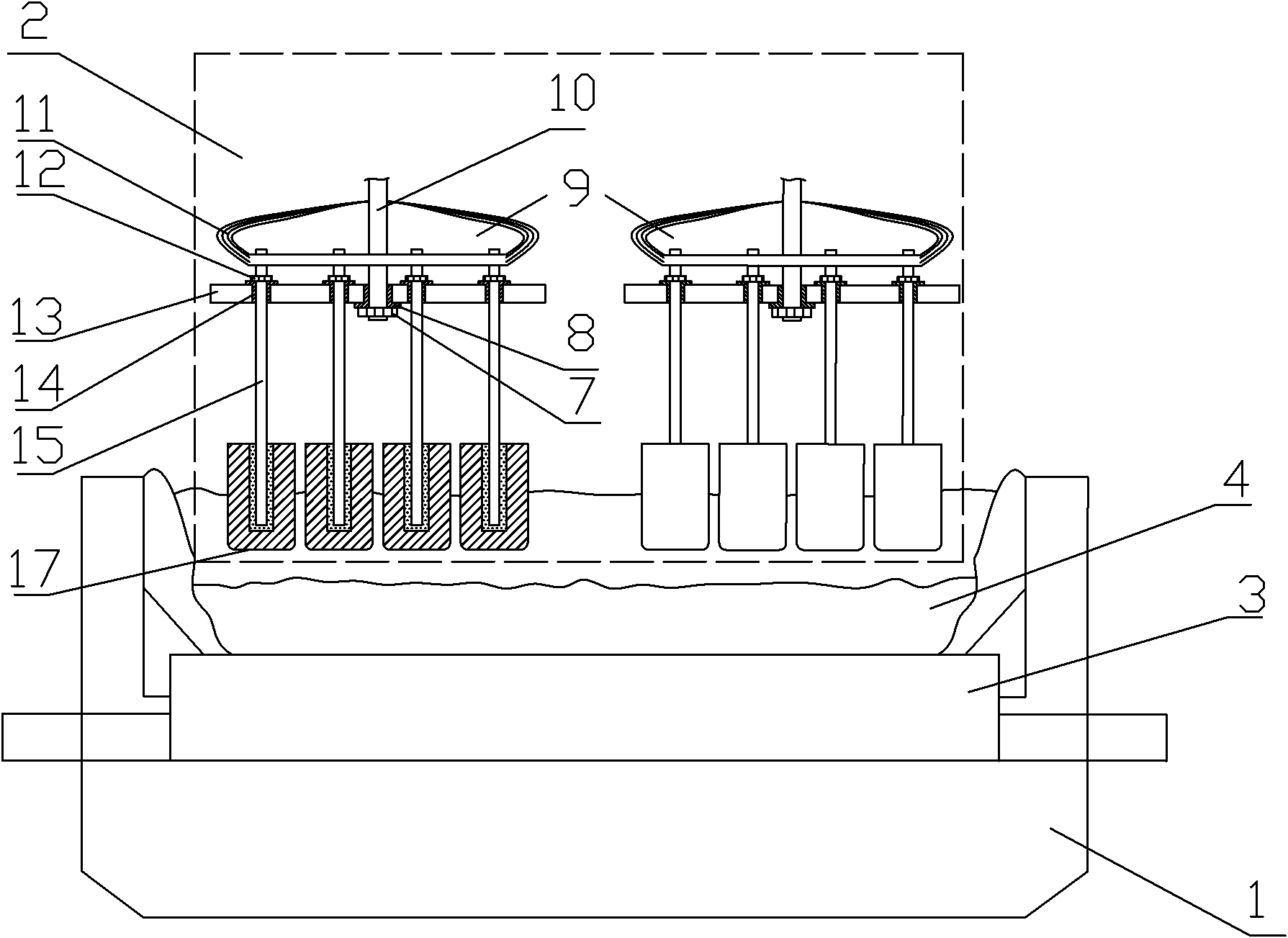

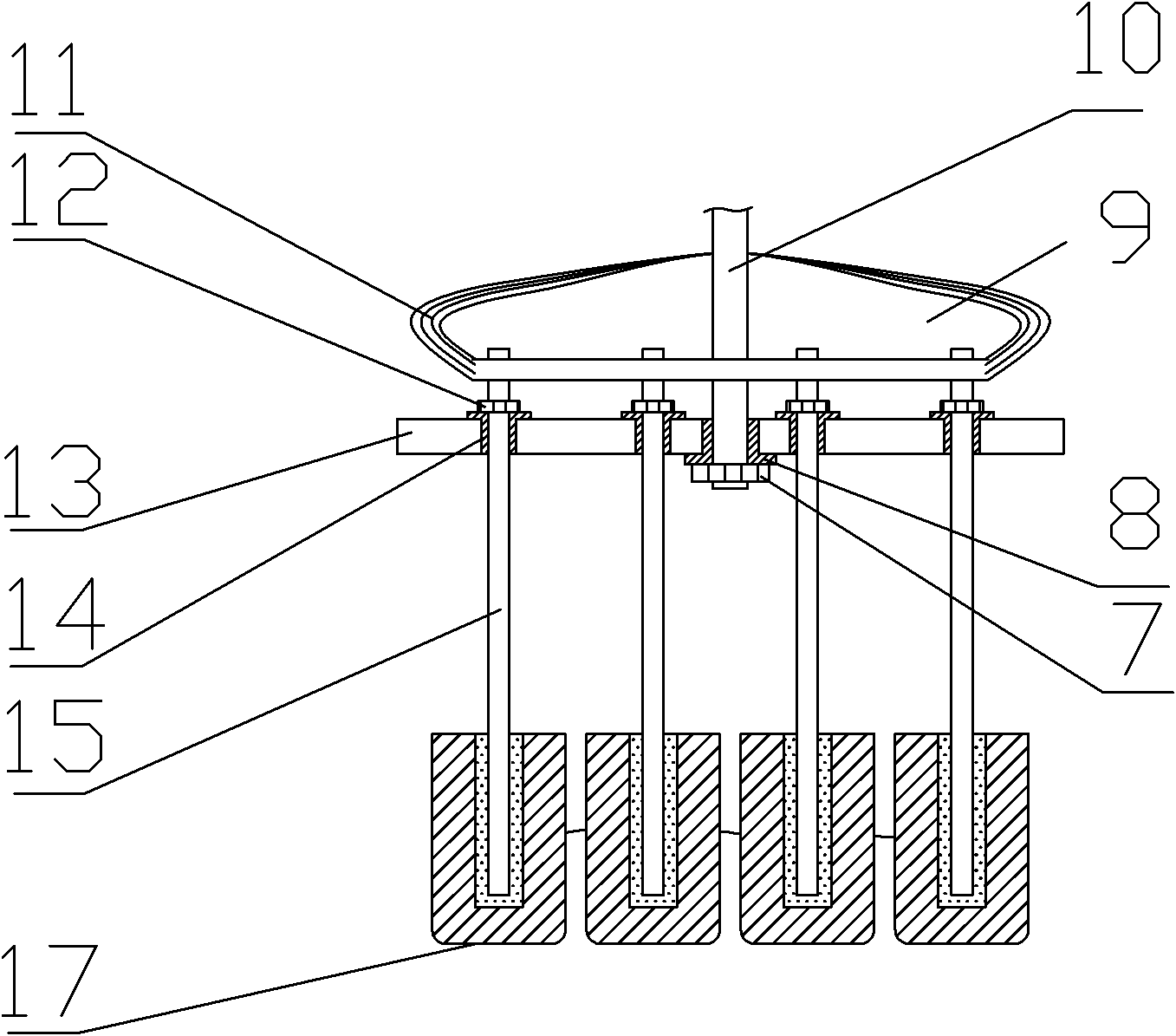

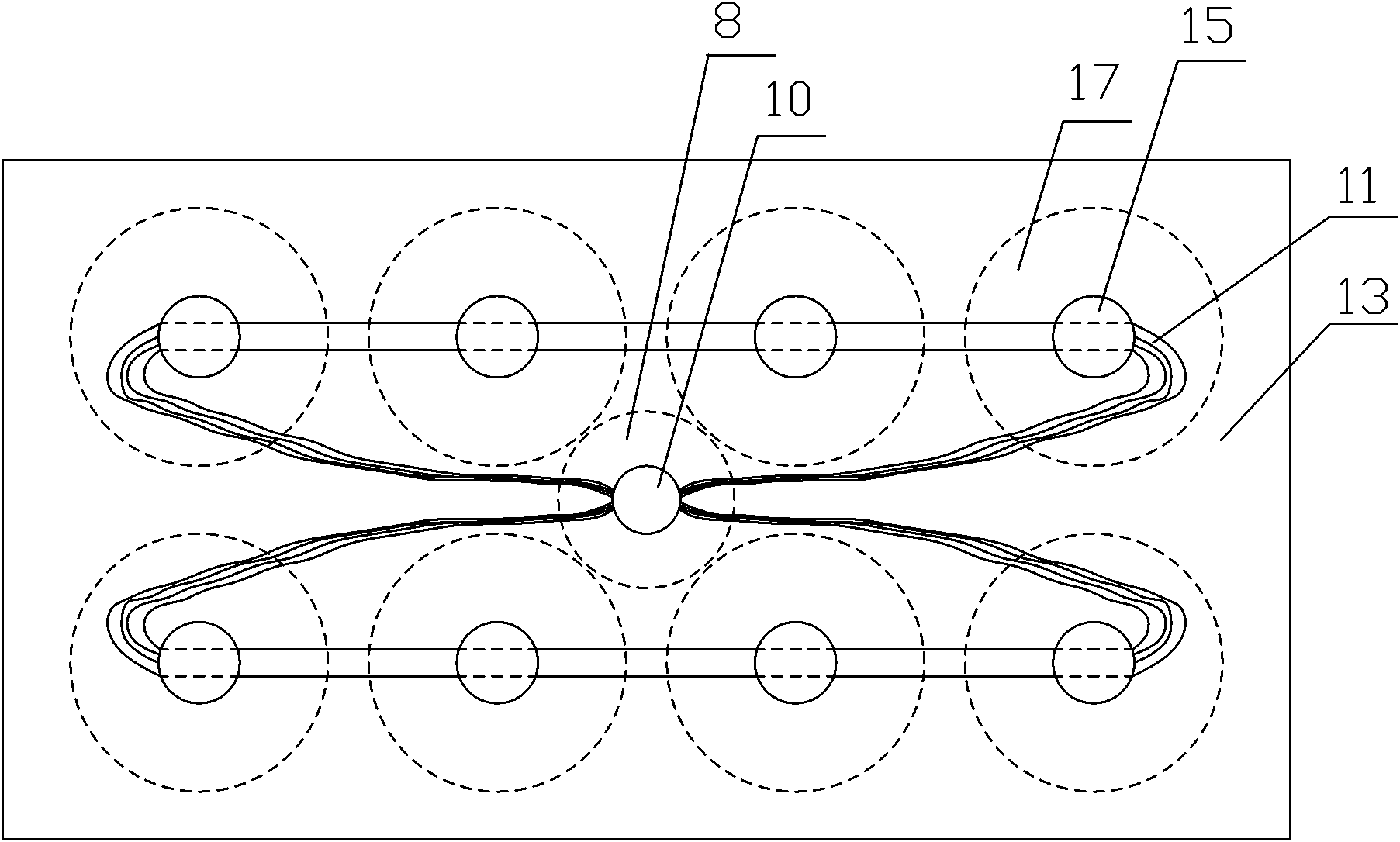

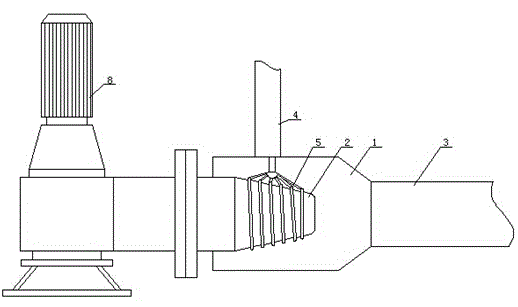

Inertial electrode low-temperature aluminium electrolytic cell

The invention discloses an inertial electrode low-temperature aluminium electrolytic cell comprising a electrolytic cell body, a metallic ceramic inertial anode, a wettable cathode and a low-temperature electrolyte, wherein, the wettable cathode is arranged at the bottom of the electrolytic cell body; the low-temperature electrolyte is arranged in the electrolytic cell body; the metallic ceramic inertial anode is arranged at the upper part of the electrolytic cell body, and end part of the metallic ceramic inertial anode extends into the low-temperature electrolyte; the metallic ceramic inertial anode is composed of at least two groups of metal ceramic inertial anode sets; each metallic ceramic inertial anode set is composed of at least two metallic ceramic inertial anode monomers; the metallic ceramic inertial anode sets and the metal ceramic inertial anode monomers in the same metal ceramic inertial anode sets are both in electrical parallel connection. The inertial electrode low-temperature aluminium electrolytic cell has reasonable structure, simple and convenient operation, stable operation, less oxygen discharge and small aluminium liquid fluctuation, low electrolytic cell voltage, low operation temperature and less energy consumption, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

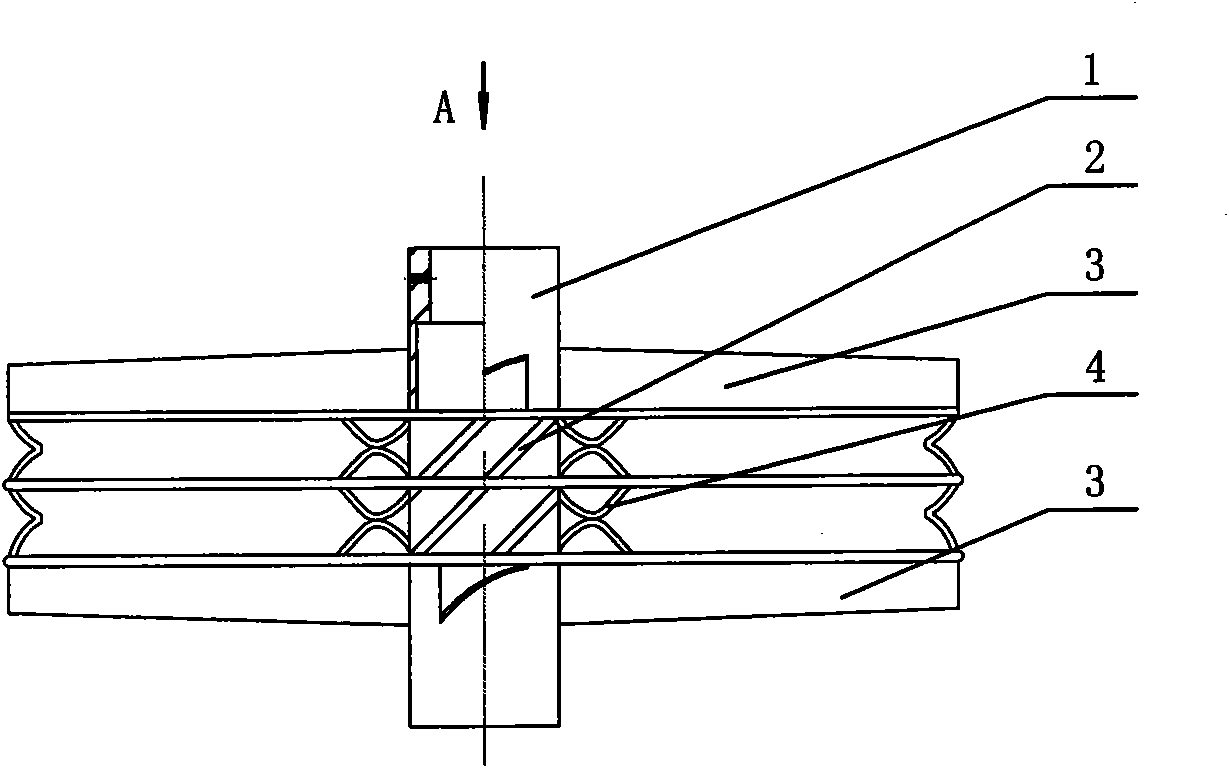

Novel centrifugal misting fan blade

InactiveCN101780367ASmall particlesDissolve quicklyUsing liquid separation agentWater flowPulp and paper industry

The invention provides a novel centrifugal misting fan blade. The novel centrifugal misting fan blade comprises a shaft sleeve connected with a water inlet tube and two fan blades fixed on the shaft sleeve, wherein the two fan blades consist of a front fan blade and a back fan blade, and a misting net is arranged between the two fan blades; the side wall of the shaft sleeve is provided with a plurality of inclined spraying slots opposite to the misting net; each fan blade comprises 3 to 4 inclined blades uniformly arranged along the shaft sleeve; an included angle between the inclined spraying slots and the shaft sleeve is 30 to 60 degrees; and the misting net is a disk-shaped steel mesh, and the misting net between the two fan blades at least comprises two layers. The centrifugal misting fan blade is mainly arranged in a waste gas smoke exhaust tube; and when the water inlet tube is driven by a motor to rotate at a high speed, water current in the water inlet tube is directly sprayed out from the inclined spraying slots in a mode of water mist and the sprayed water mist is blocked by the rotary misting net to be further broken into the water mist formed by smaller particles, so that the misting effect is better, the cross section of the smoke exhaust tube is fully filled with the water mist and poisonous substances and smoke dust in the waste gas can be quickly dissolved in the water mist.

Owner:张宏生

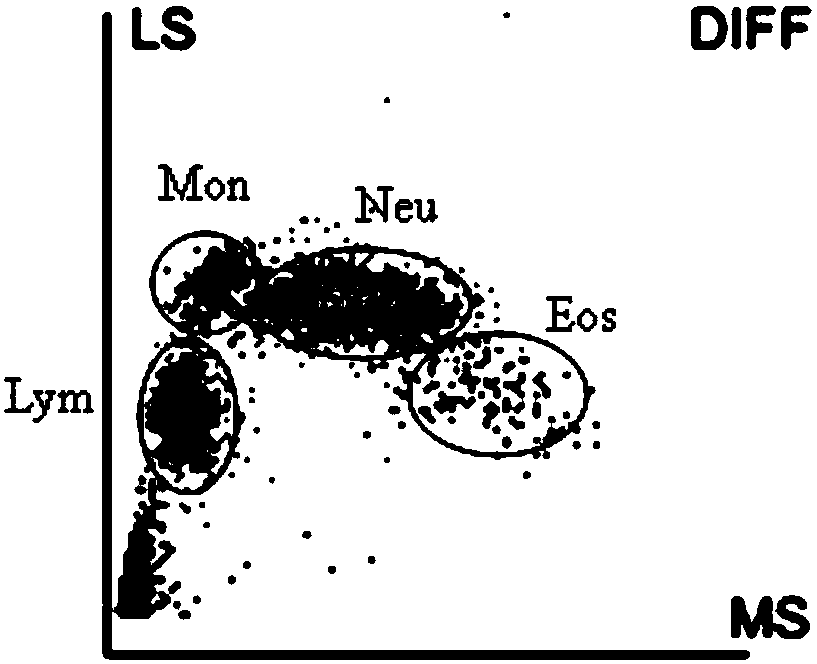

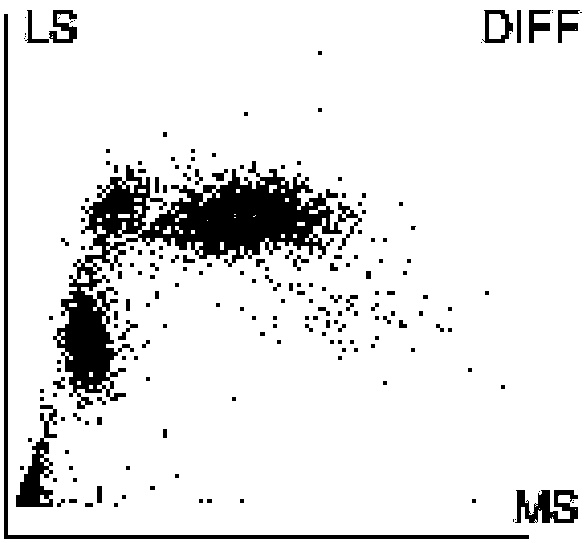

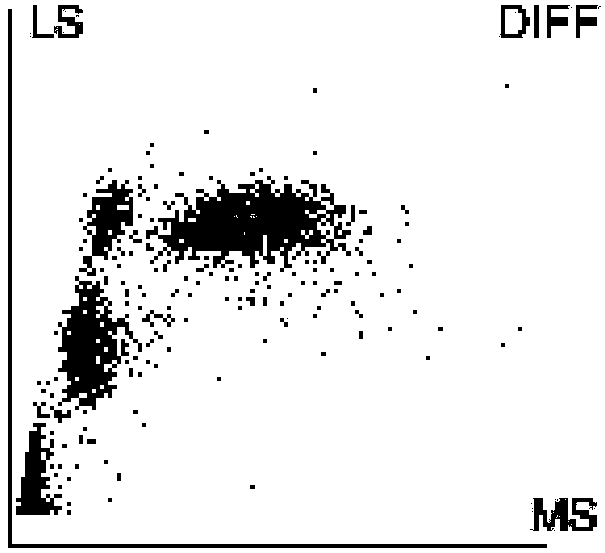

White blood cell classification reagent

PendingCN108414427ASave raw materialsImplement classificationIndividual particle analysisRed blood cellNeutrophil granulocyte

The invention discloses a white blood cell classification reagent, which comprises the following raw materials: an ionic surfactant, a pH value adjusting buffer, an alkali metal salt for adjusting osmotic pressure, and an alcohol capable of dissolving and accelerating. According to the present invention, with the white blood cell classification reagent, white blood cells can be divided into four cell clusters, and the boundary between each cell cluster is clear; compared to the traditional five-class hemolytic agent, the white blood cell classification reagent of the present invention has thefollowing advantages that the boundary between the monocyte clusters and the neutrophil cluster is clear, and the clustering property is strong; the white blood cell classification reagent has characteristics of strong low-temperature hemolysis ability and wide temperature range, and can rapidly dissolve red blood cells in a low-temperature environment, ensure the normal classification of white blood cells, and reduce the manufacturing cost of the instrument on temperature control; and the white blood cell classification reagent further has advantages of low raw material cost, environmental protection and no toxicity, and can classify white blood cells by requiring only one reagent so as to achieve advantages of convenience, time saving and reduced production cost.

Owner:SHENZHEN DYMIND BIOTECH

Salt mist physical-therapy room

A salt fog physiotherapy center is composed of the mineral salt solution and salt fog vapor room, and features that the humidity, temp and the granularity of atomized salt solution are controlled for playing the full physiotherapeutic function.

Owner:成都卓成健康管理有限公司

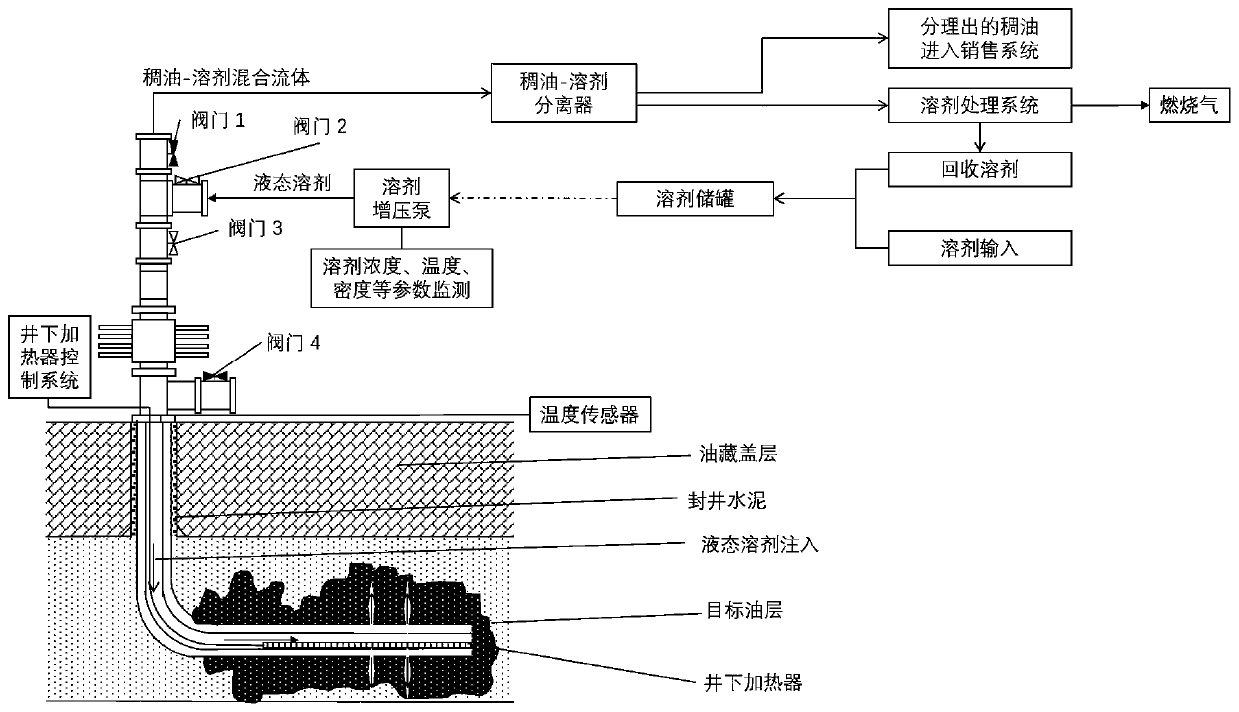

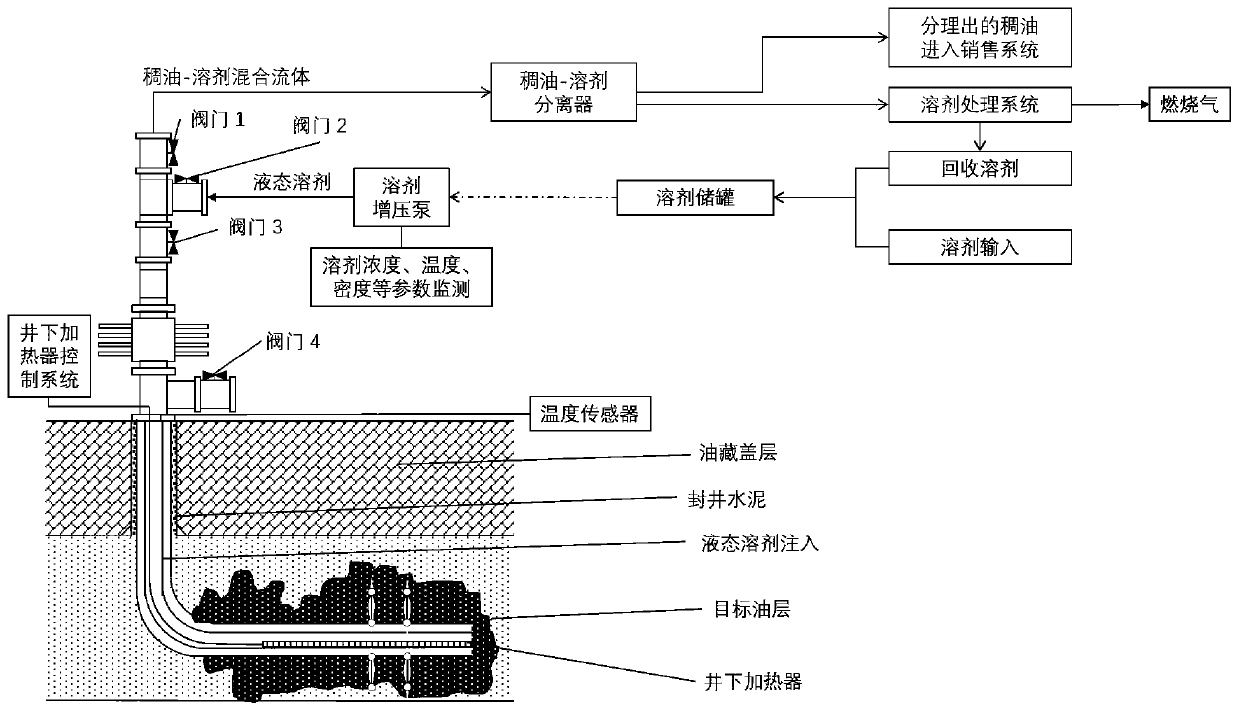

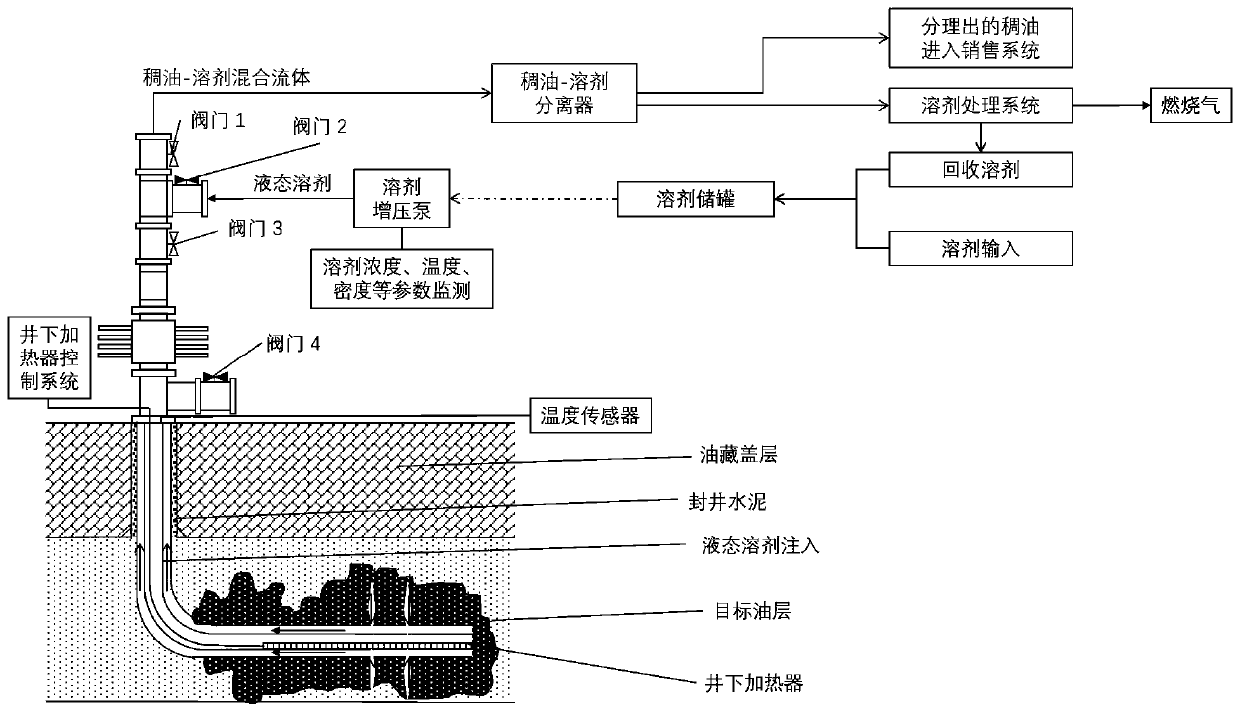

Heavy oil recovery method and system capable of being recycled and heating injection solvent underground

The invention discloses a heavy oil recovery method and system capable of being recycled and heating an injection solvent underground. The method comprises the following steps that S1, single-well production operation is carried out; S2, production separation operation is carried out, specifically, the produced fluid is injected into a gas-liquid separator, oil-gas separation is carried out, the solvent extracted along with crude oil is separated from heavy oil, the heavy oil is conveyed into a sales link through pipelines, and the separated solvent is treated, recycled and input into a solvent storage tank for cyclic utilization; and S3, adjacent well cooperative operation is carried out, specifically, a plurality of wells are arranged to form a well group. The method has the advantages that solvent is injected into the stratum at normal temperature, and due to the fact that the saturation pressure of the solvent rises along with the increase of the temperature, when the liquid solvent is injected into the stratum under the high-temperature condition, energy consumption is large; and under the normal temperature condition, the solvent can be compressed into a liquid state under the low pressure, and the solvent is injected into the stratum to the maximum extent in a liquid state mode.

Owner:SOUTHWEST PETROLEUM UNIV

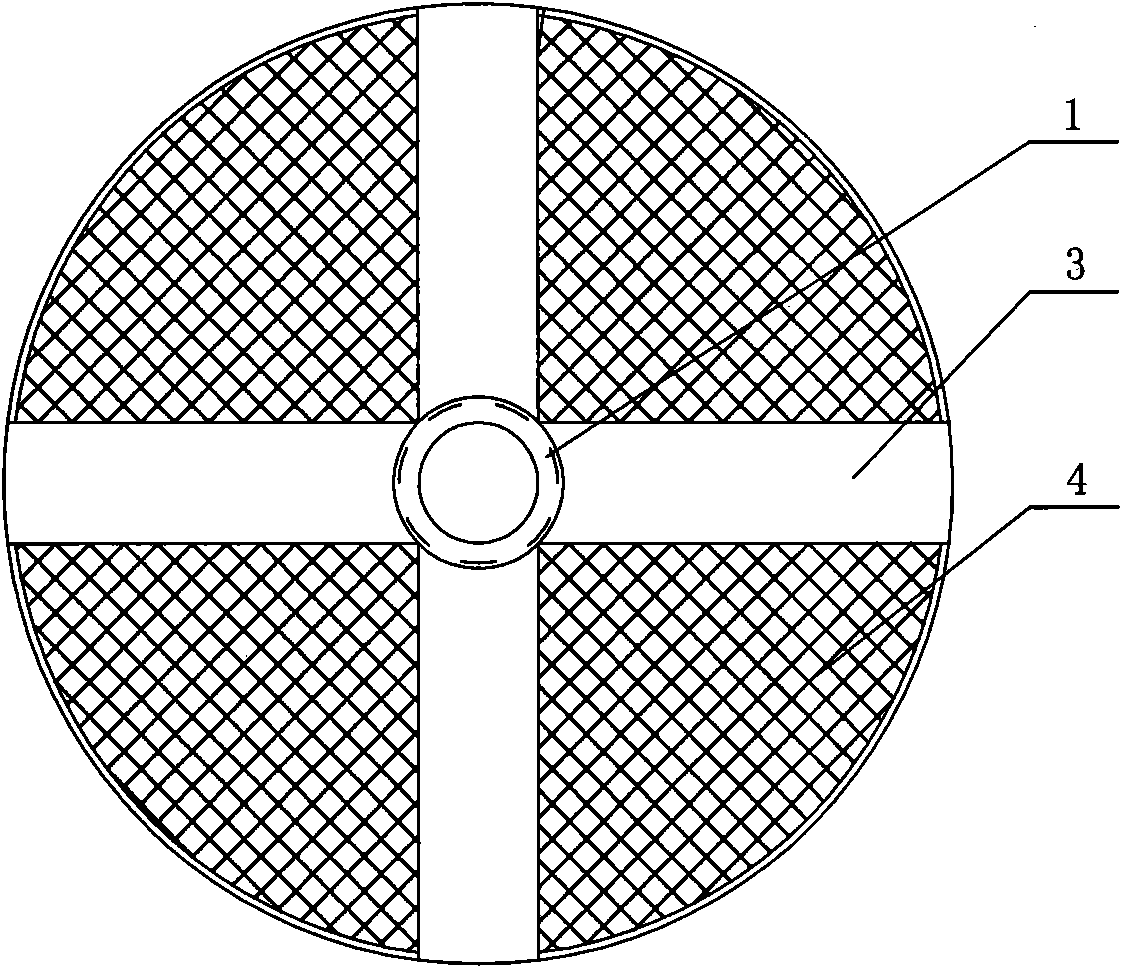

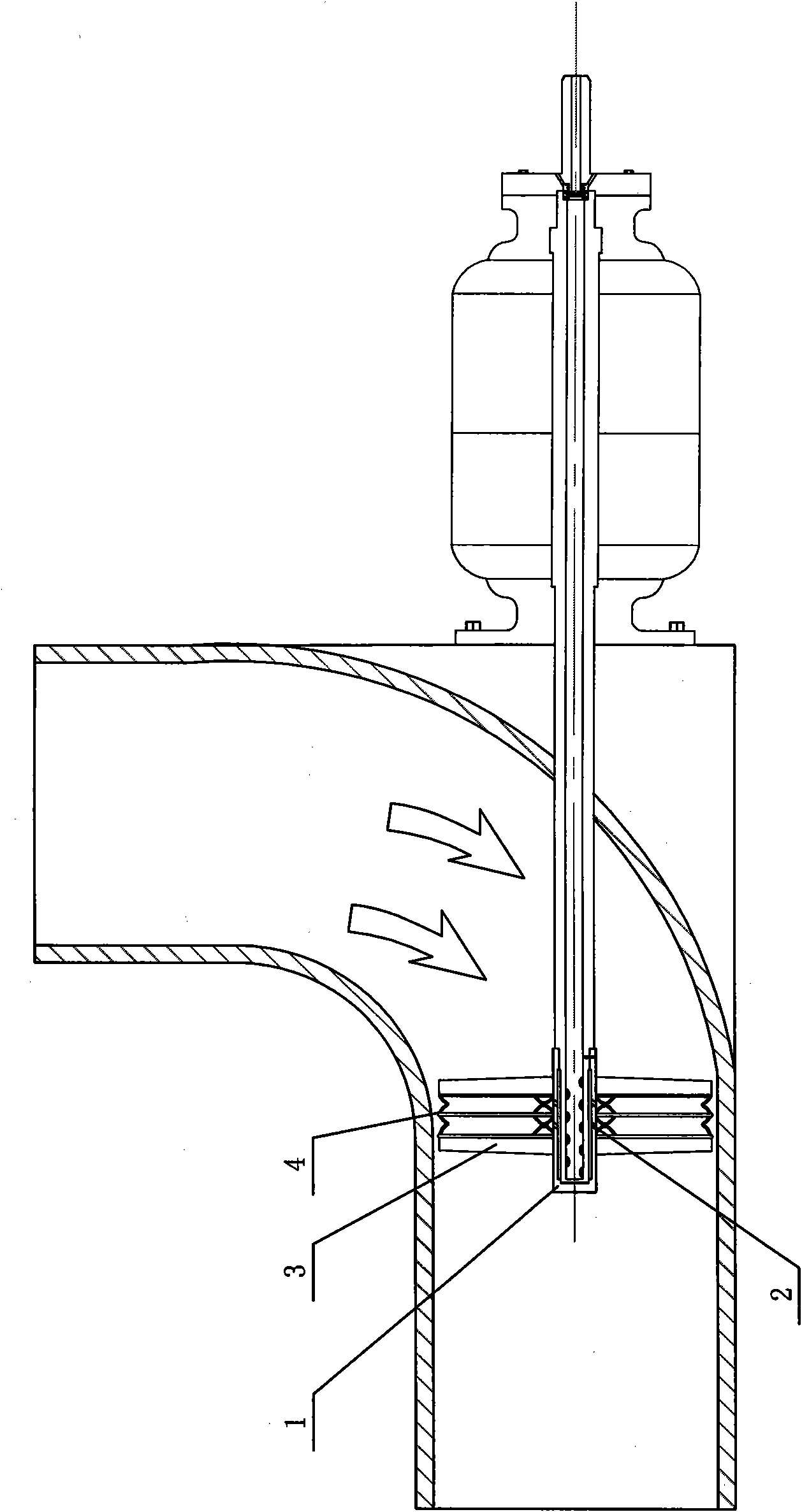

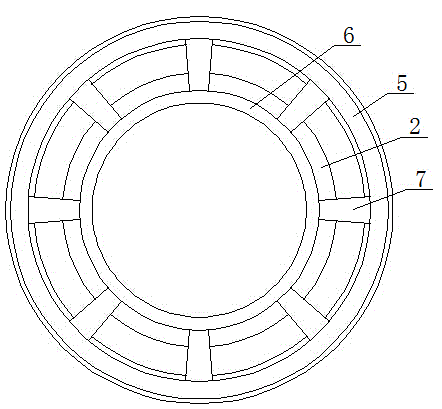

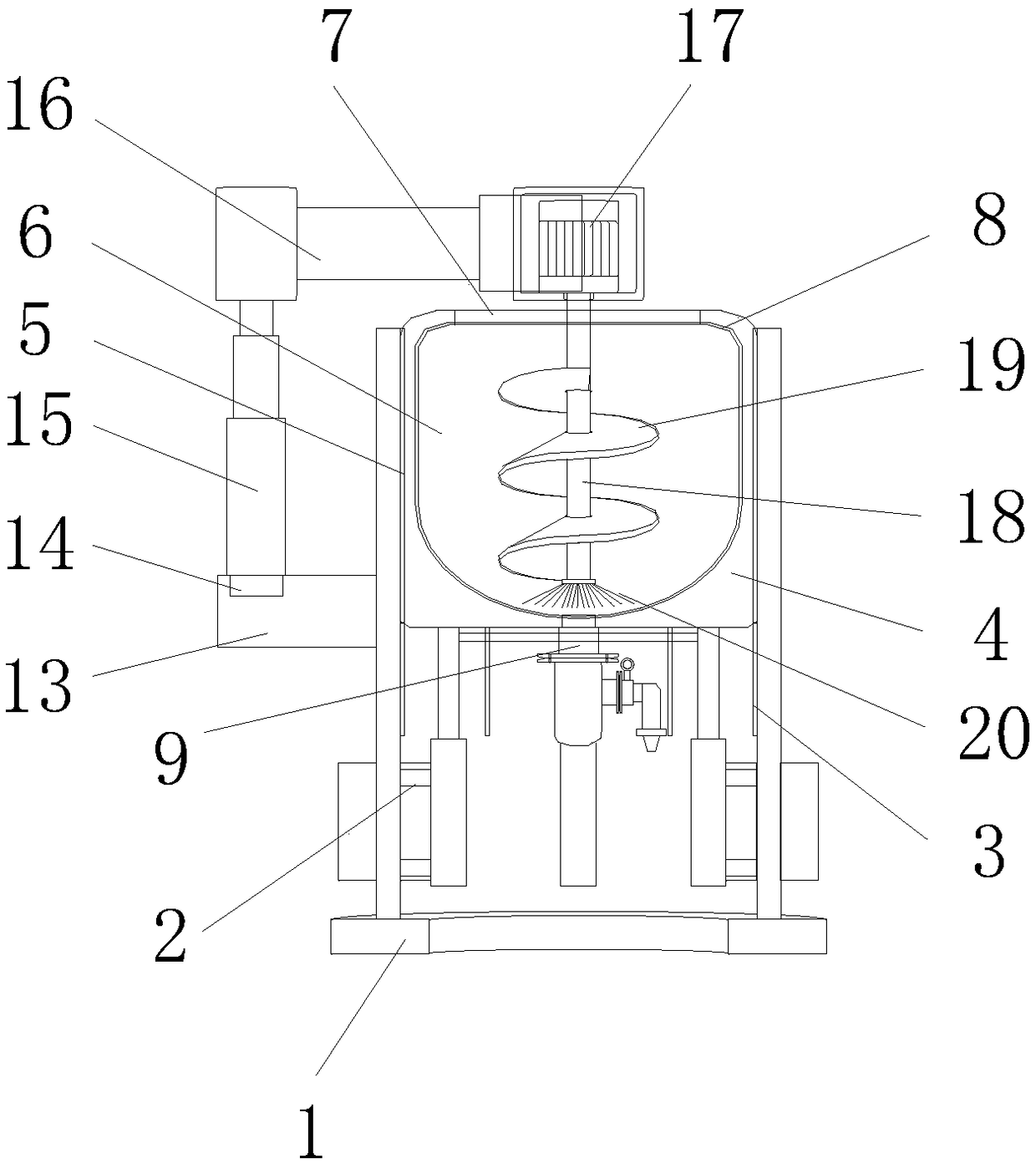

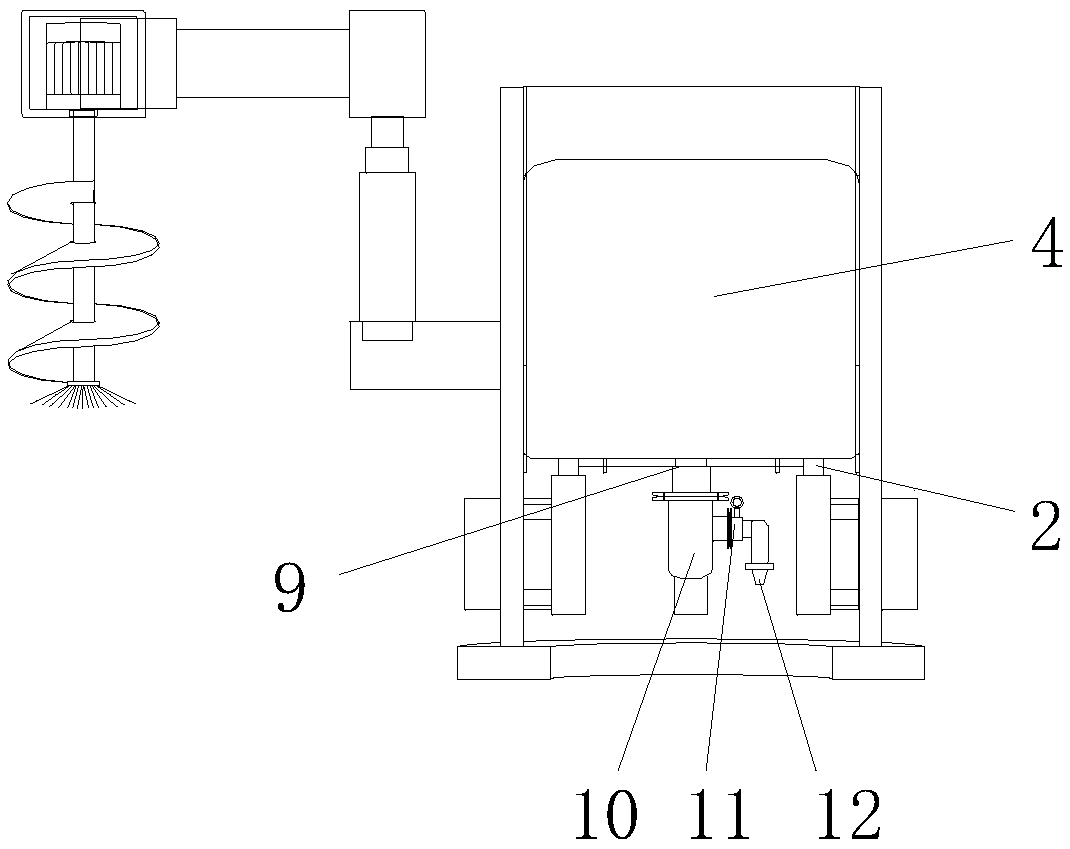

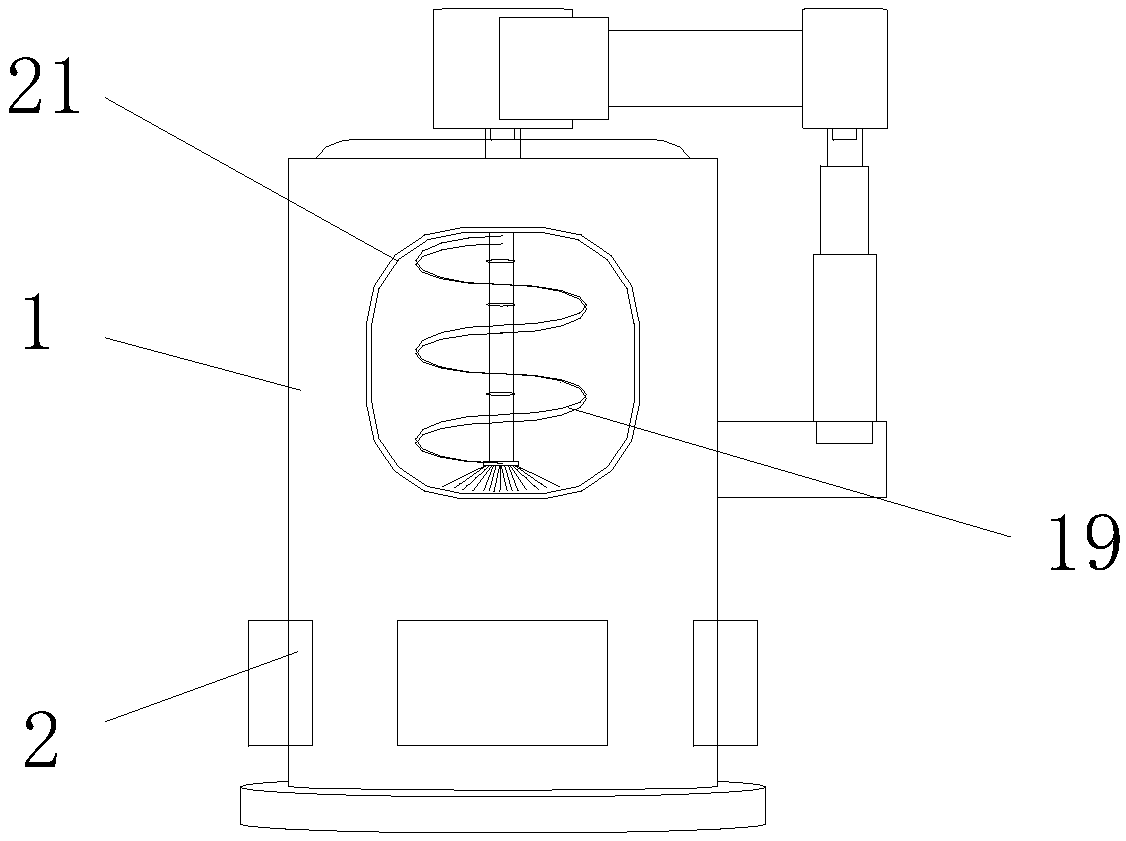

Spiral jet aerator

InactiveCN104909478ADissolve quicklyImprove the efficiency of dissolved airWater aerationSustainable biological treatmentSewage treatmentNozzle

The invention belongs to the technical field of sewage treatment equipment and discloses a spiral jet aerator. The spiral jet aerator is used for solving the problem that the air dissolution efficiency is low in the conventional aerator. The spiral jet aerator disclosed by the invention comprises a water pump, wherein the water pump is connected with an aerator; the aerator comprises an air suction chamber and a nozzle; the nozzle is sleeved by one end of the air suction chamber; the other end of the air suction chamber is connected with a throat tube; the air suction chamber is further communicated with an air suction tube; spiral guide plates are arranged inside the nozzle; multiple through holes are formed in nozzles between adjacent spiral guide plates; the air suction tube is connected with at least two air inlet branch tubes; the air inlet branch tubes sleeve the periphery of the nozzle; the air inlet branch tubes are uniformly provided with air inlets of which the number is the same as that of the through holes; and the air inlets are communicated with the through holes by virtue of pipelines. The spiral guide plates are arranged inside the nozzle, and the air inlet branch tubes are arranged at the periphery of the nozzle, so that air is introduced into the nozzle, and the air can be rapidly dissolved in water. Therefore, the air dissolution efficiency of air is improved, and the sewage treatment effect is improved.

Owner:SICHUAN KAIMING MACHINERY MFG

Health-preserving health-care wine

InactiveCN101130736ADissolve fully and quicklyDissolve quicklyAlcoholic beverage preparationEngineeringCell wall

The invention provides a health preserving wine and the preparing method. The preparing method comprises the following steps: putting matrimony vine, jujube in the vacuum bulking device after picking and cleaning; discharging the steam after adding the steam for 10-30 minutes; keeping heating the vacuum bulking device for 5-15 minutes; reducing the pressure to negative 0. 04-0. 06MPa at once; drying in the vacuum; getting matrimony vine and jujube with the broken wall; immersing matrimony vine and jujube with the broken wall in the white spirit for 70-90 days; filtering in order to remove the solid material; getting the health preserving wine. Breaking the wall of matrimony vine and jujube can dissolve the plant polysaccharide and flavone in the wine quickly and abundantly, generally immersing for 70-90 days can dissolves more than 90%, what's more, breaking the wall of the immersing material and opening the cell wall with the nutrient substance in the material in order to immerse the nutrient substance in the cell out by the wine liquid shorten the production cycle of the health preserving wine and increase the nutrient component in the wine. The preparing technology is fit for the production of the health care wine of the other Chinese herbal medicine and nourishing diet.

Owner:王铁岩

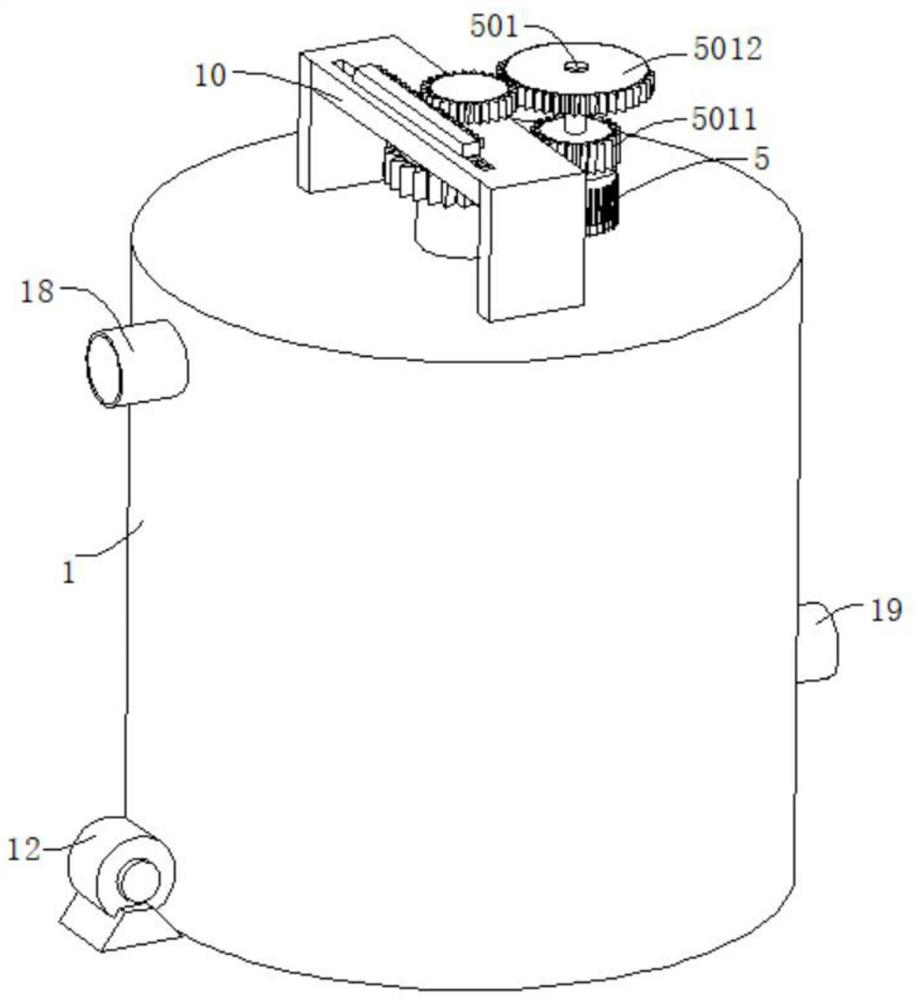

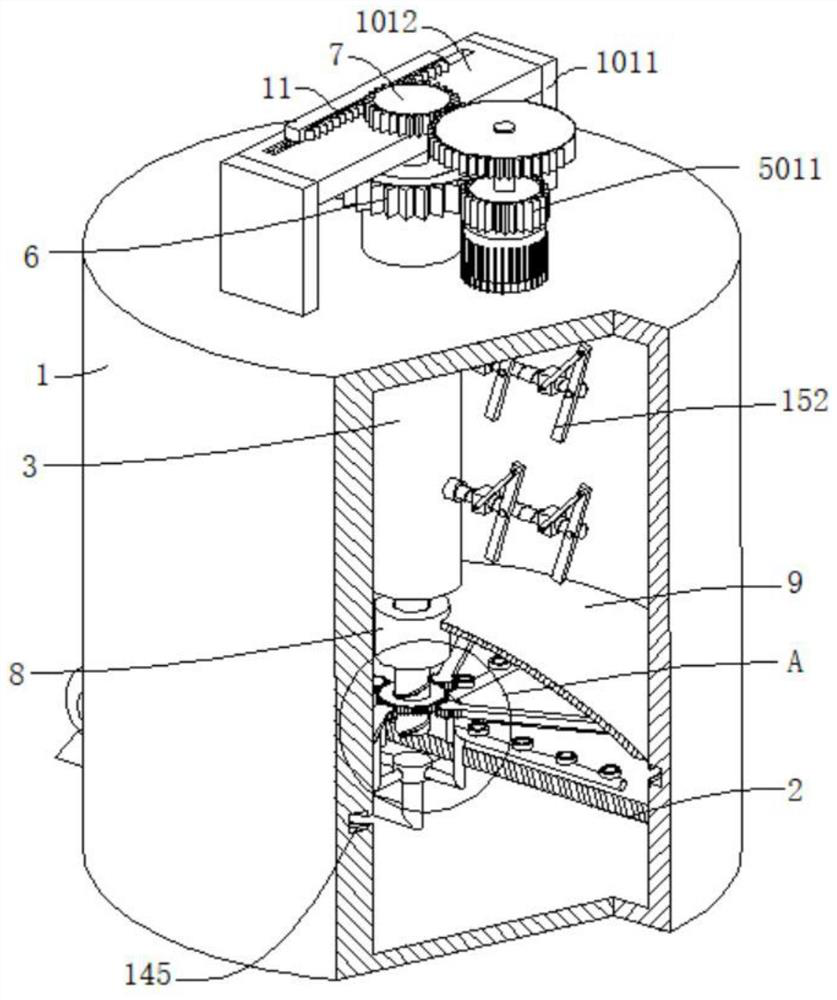

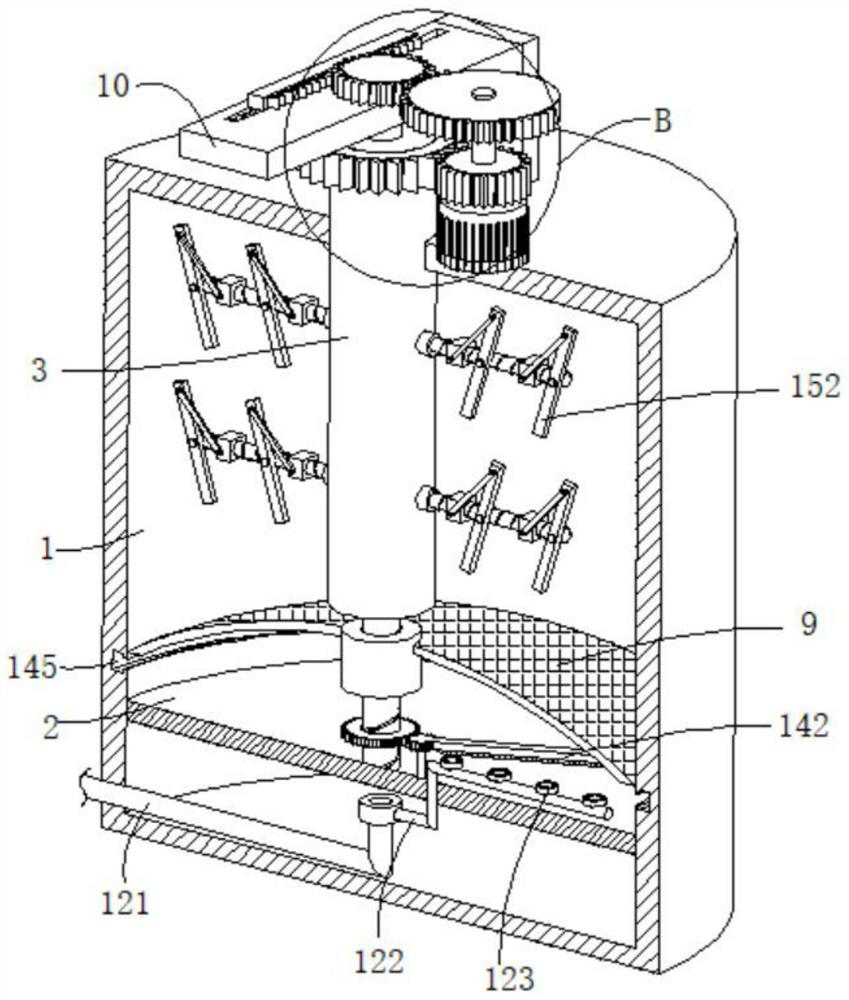

Combined aeration treatment device for chemical sewage

InactiveCN112174347AImprove aeration efficiencyImprove the aeration effectWater aerationSustainable biological treatmentUpflow velocityWastewater

The invention provides a combined aeration treatment device for chemical sewage, which comprises a tank body, an aeration mechanism is arranged in the tank body, a bottom plate is connected to the inner wall of the tank body, a sleeve is rotatably connected to the inner wall of the top of the tank body, a stirring mechanism is connected to the outer wall of the sleeve, a threaded rod is rotatablyconnected into the sleeve through a first bearing, the bottom of the threaded rod is rotationally connected into the bottom plate, the outer wall of the top of the tank body is connected with a motor,the output end of the motor is connected with a rotating shaft, the outer wall of the rotating shaft is connected with a first gear and a second gear, and the second gear is a half gear. According tothe invention, large bubbles can be conveniently divided into small bubbles, the rising speed of the bubbles in the wastewater is slowed down, the mixing efficiency of the bubbles and the wastewaterin the same time is increased, and the small bubbles can more quickly dissolve oxygen into the water so as to improve the concentration of dissolved oxygen, so that the sewage treatment effect is improved, and the cost is lower.

Owner:杭州海科杭环科技有限公司

Pigment mixing device with anti-seepage structure for garment dyeing and printing

InactiveCN109395651ADissolve quicklyAvoid LeakageRotary stirring mixersTransportation and packagingHydraulic cylinderEngineering

The invention discloses a pigment mixing device with an anti-seepage structure for garment dyeing and printing. The pigment mixing device comprises a machine seat, a material mixing tank, an extensionrod and a filter screen element, wherein hydraulic cylinders are arranged in the center positions of the back end and the two sides of the machine seat, and convex blocks are fixed on the inner sidewall surface of the machine seat at equal intervals; grooves are formed in the outer side surface of the material mixing tank at equal intervals, and a cavity is formed inside the material mixing tank, and the upper end surface of the material mixing tank is provided with a material feeding opening; the extending rod is welded on the left side surface of the machine seat, and a rotating shaft is fixed inside the upper end of the extending rod; the back end surface of the material mixing tank and the back end surface of the machine seat are both fixedly provided with observation windows; the filter screen element and a reserved cavity are mutually connected to each other through a support element. The pigment mixing device with the anti-seepage structure for garment dyeing and printing hasthe advantages that a filter element is used for filtering pigment water through the filter screen element; by using the structure, residue inside the device can be well filtered out; and the pigmentseepage condition due to the accumulation of the residue in the pigment precipitated and adsorbed inside a valve can be avoided.

Owner:嘉兴铭皓服装有限公司

Compound disinfectant product and preparation thereof

InactiveCN107318886ADestroy surface protectionDissolve quicklyBiocideDisinfectantsDisinfectantCorrosion

The invention relates to a compound disinfectant product and preparation thereof. The compound disinfectant product is prepared from the following components in percentage by mass: 1 percent to 7 percent of hydrogen peroxide, 1 percent to 10 percent of ethanol and the balance of water; the compound disinfectant product is prepared by the following method: adding the hydrogen peroxide and the ethanol into the water and uniformly stirring to obtain a target product. Compared with the prior art, the compound disinfectant product has the advantages of rapid sterilization speed, broad spectrum and high effect, wide application range, small corrosion, no residue and no need of cleaning, no danger and no generation of waste liquid in a production process and the like.

Owner:SHANGHAI HABO CHEM TECH

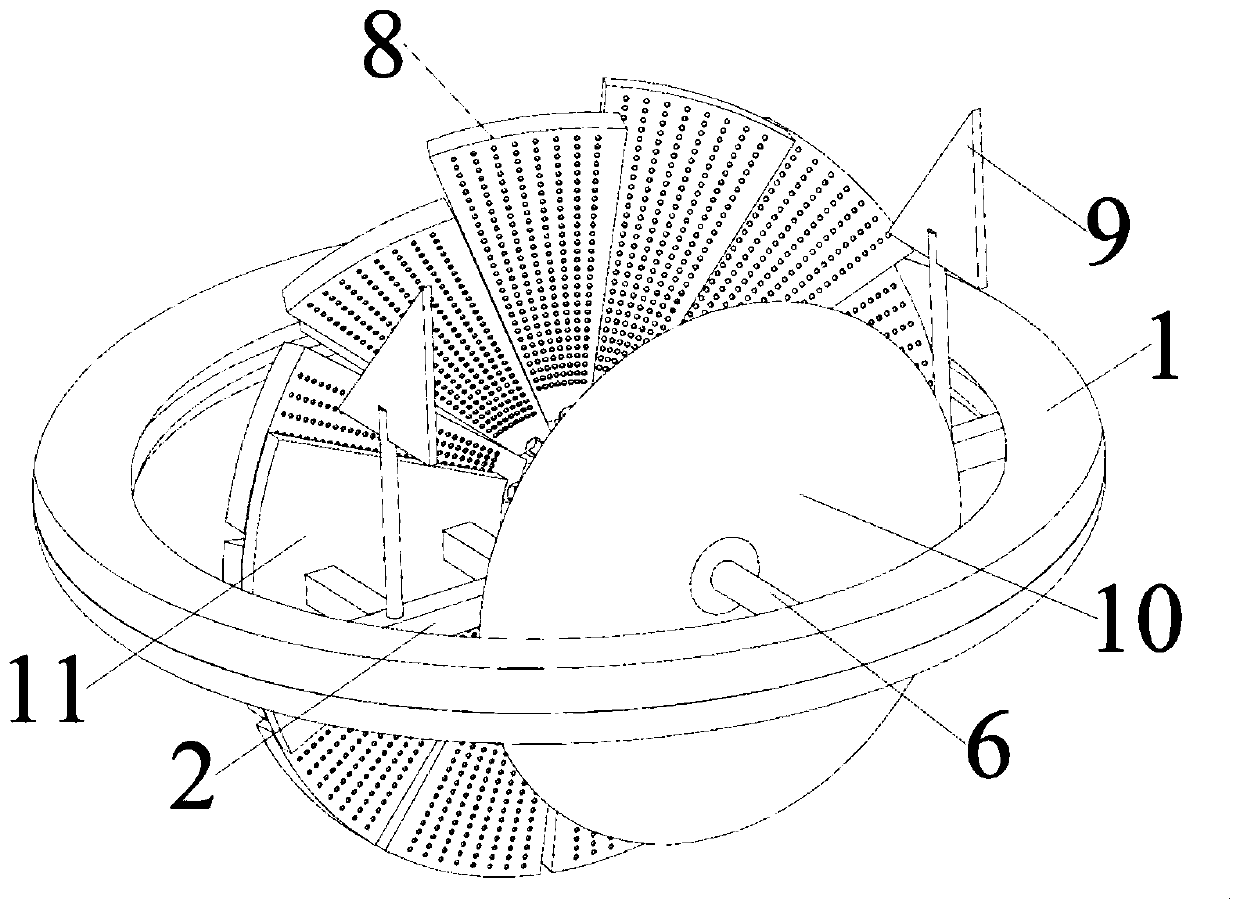

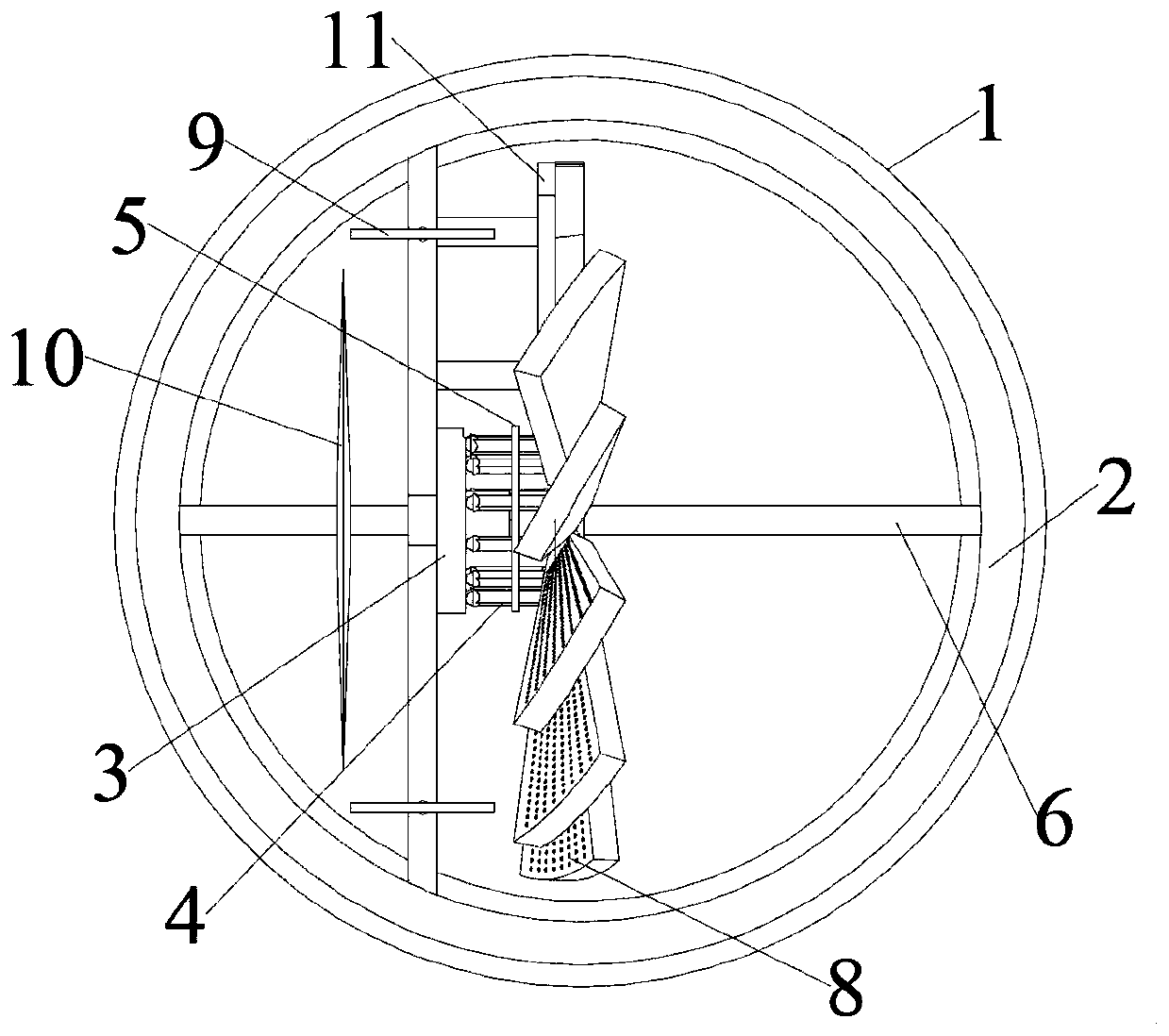

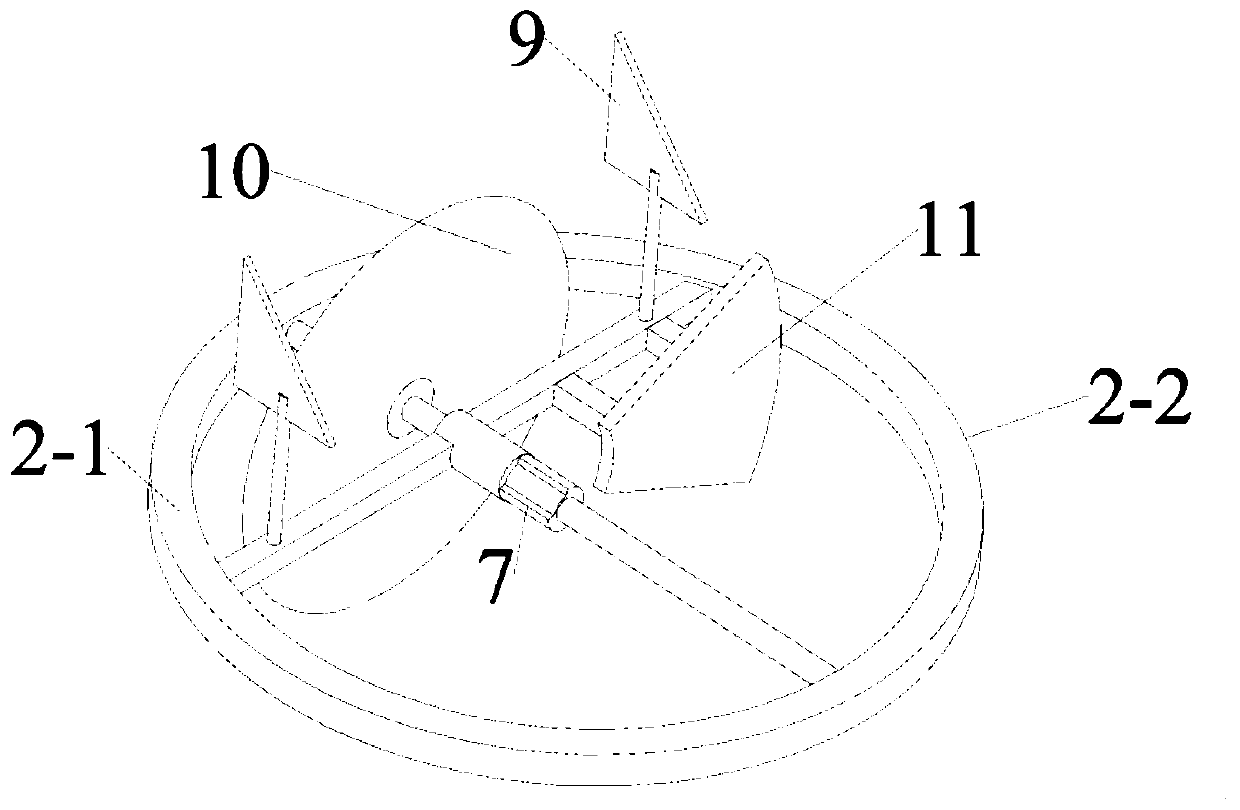

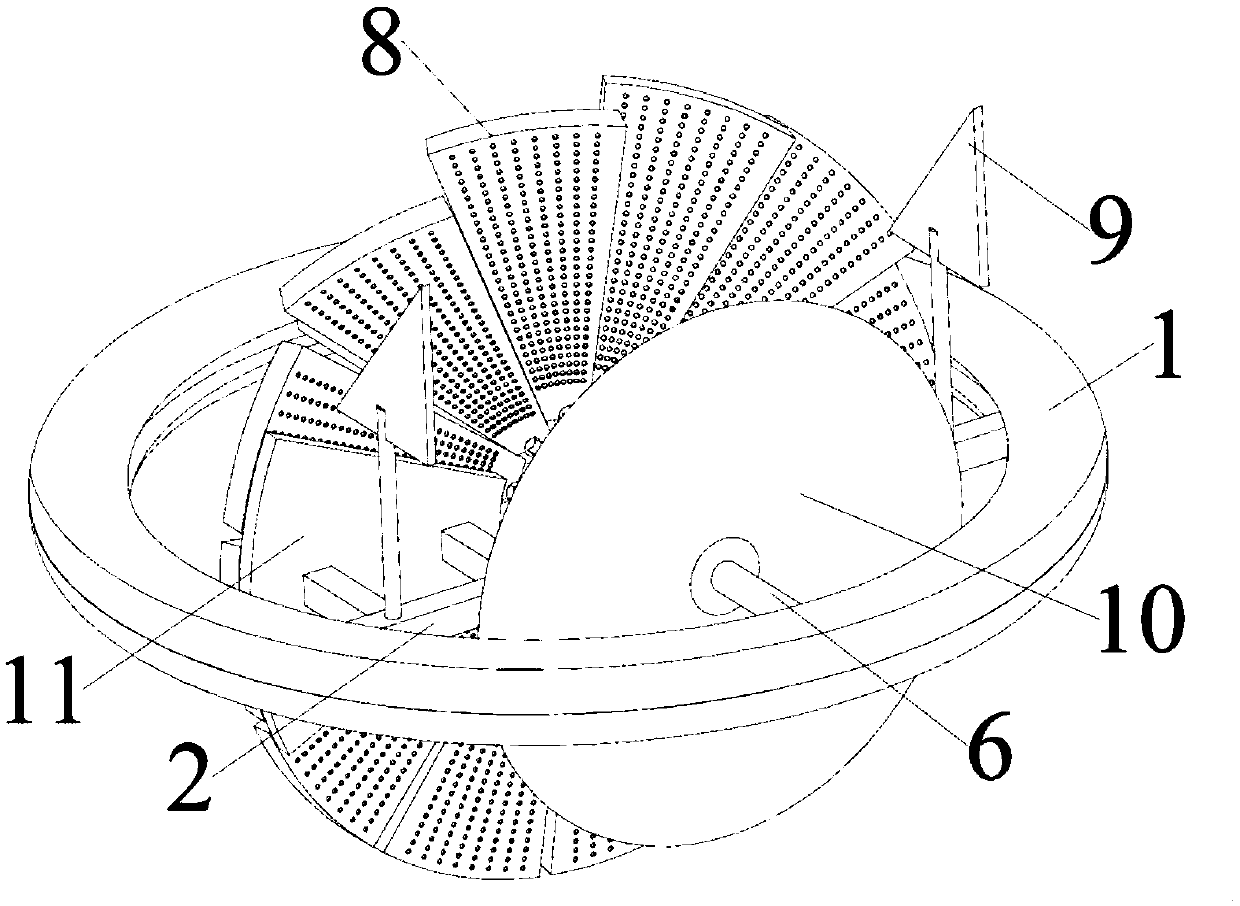

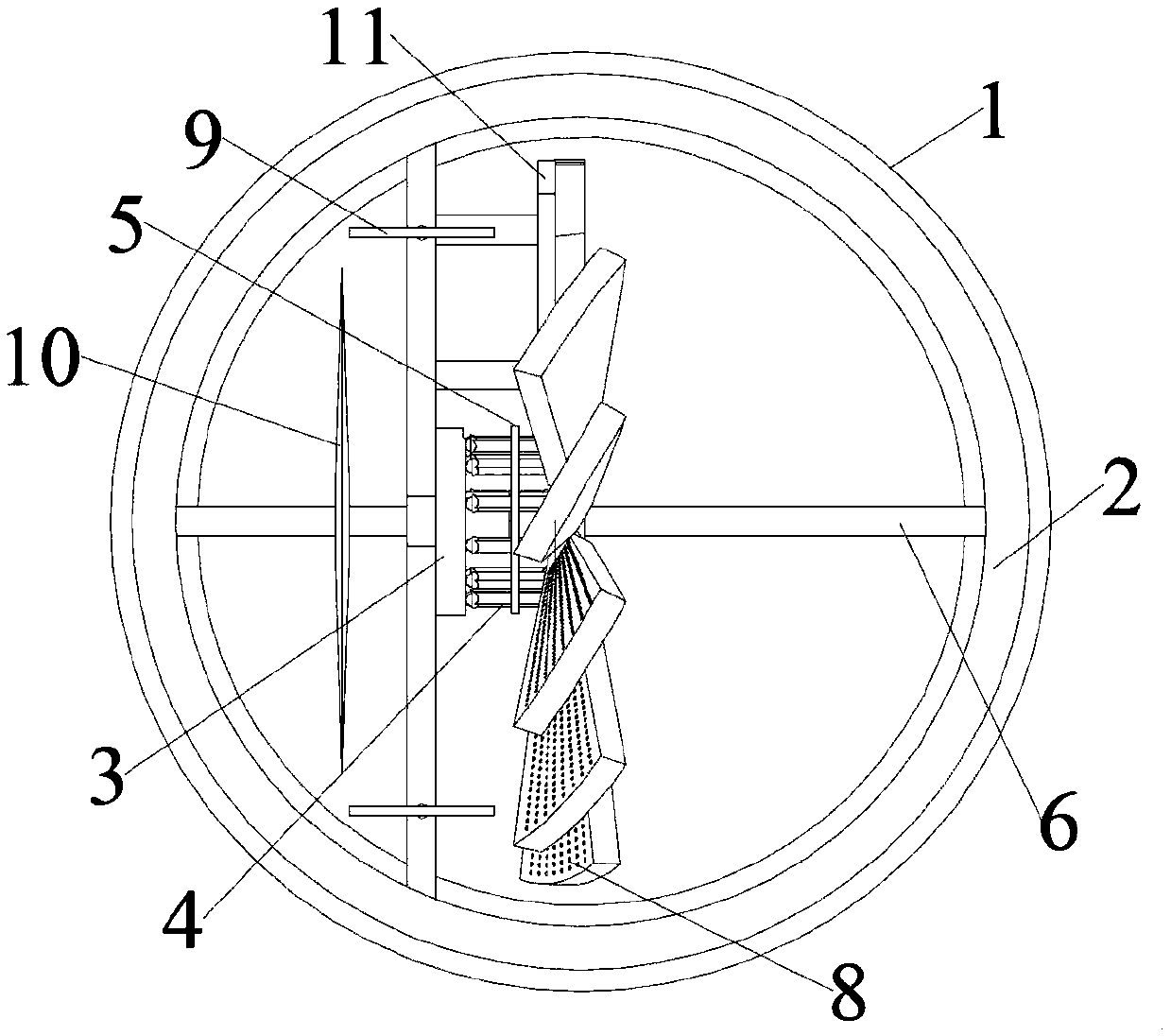

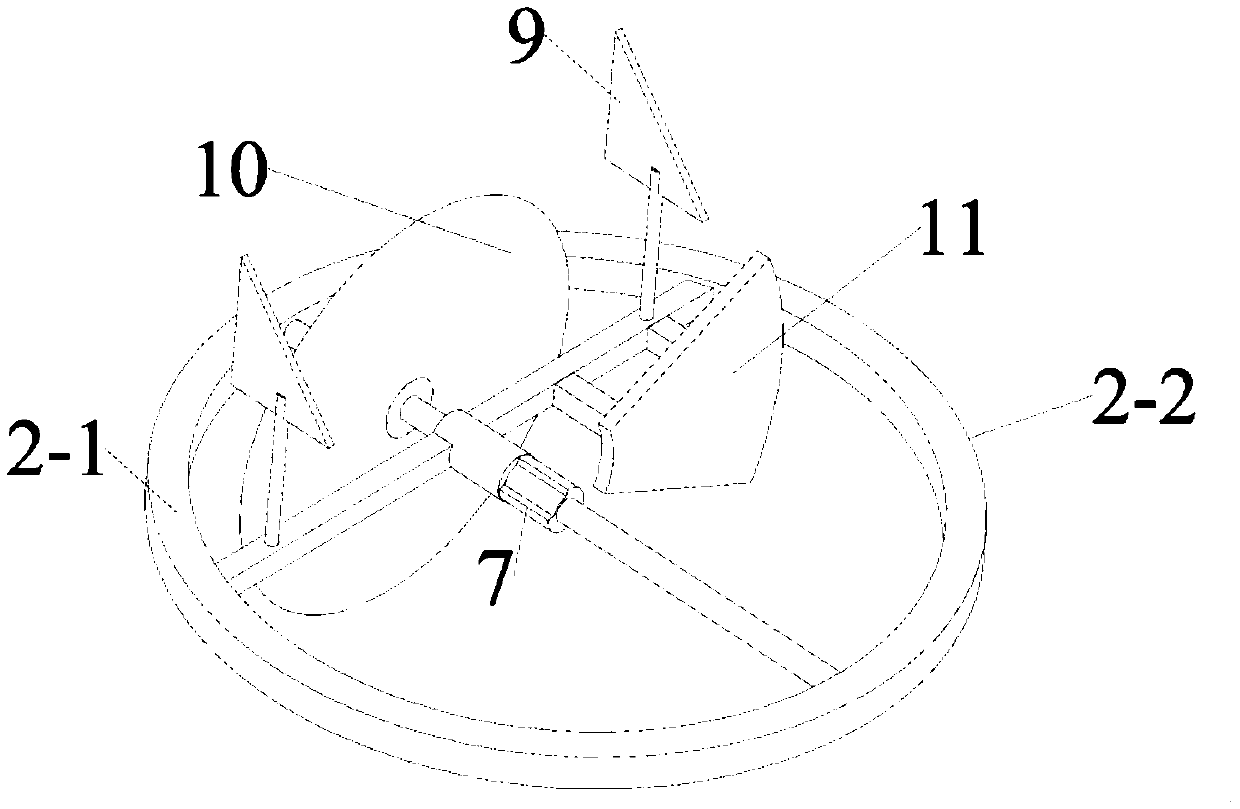

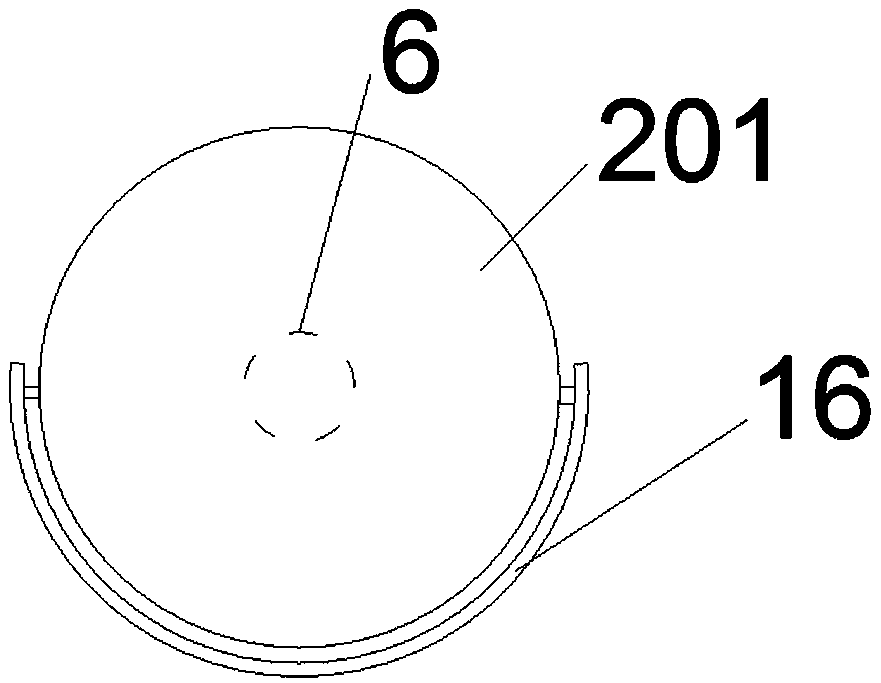

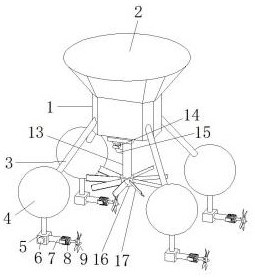

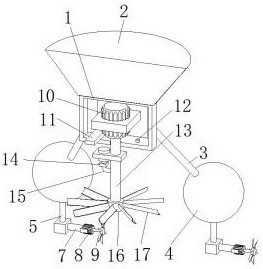

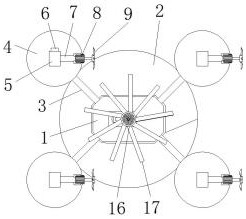

River nitrogen removal promoting device without external air source

ActiveCN109892282AReduce consumption costPromote nitrogen removalPisciculture and aquariaNitrogen removalBogie

The invention discloses a river nitrogen removal promoting device without an external air source. An existing aeration device has the problems of high cost, continuous consumption of electrical energyand low service life. The device comprises a floating ring, a bogie, an end cam, a sliding rod, a rotating disc, a main rotating shaft, an air sealing block, aeration blades, a wind chasing plate andan air blocking block. The bogie includes a rotating ring and a support frame. The rotating ring and the floating ring constitute a rotating pair. The main rotating shaft is supported on the rotatingring. The wind chasing plate is fixed on the support frame. The rotating disc includes a blade base column and a sliding rod disc. The n aeration blades are arranged on the blade base column. The aeration blades are hollow. A plurality of aeration holes are formed in the aeration blades. The working profile of the end cam is composed of a push-out section, a transition section and a retraction section. The sliding rod disc is provided with n sliding rod through grooves uniformly formed in the circumference direction of the sliding rod disc. The device is driven by the wind, and the continuousaeration of the water in the river can be achieved without external power.

Owner:DONGGUAN DINGMAO SPRAY PURIFICATION SYST

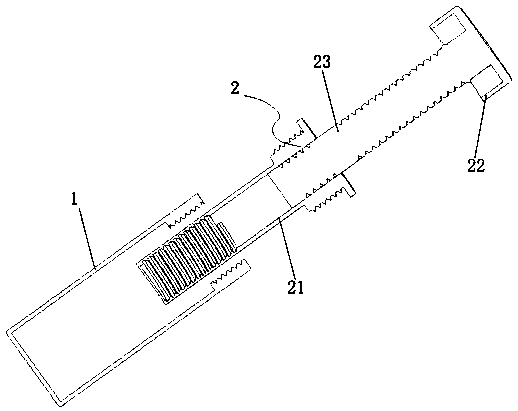

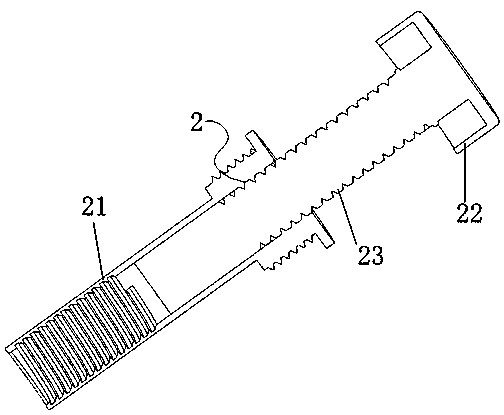

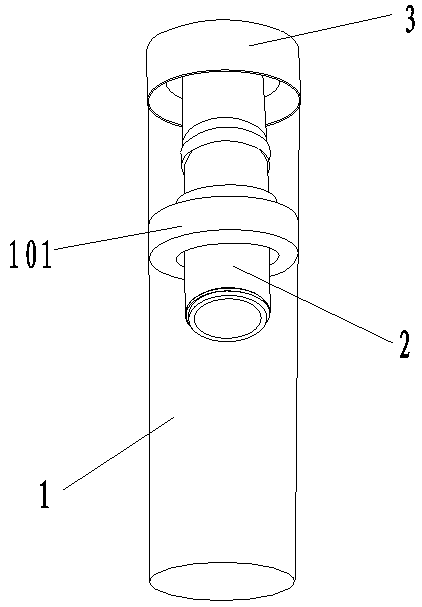

A feces sampling device

The invention relates to the technical field of medical instruments, specifically to a feces sampling device. The feces sampling device comprises a collector and a sampler, wherein the sampler is placed in the collector in a nestable way, the collector is detachably and hermetically connected with the sampler, a sample pushing device is arranged in the sampler and can carry out relative displacement of a certain distance in the sampler, the sampler is hermetically connected with the collector while the sample pushing device is pushing a sample out from the interior of the sampler, and the sampler is detachably disconnected with the collector while the sample pushing device is moving from a sampling mouth to the interior of the sampler to expose a sampling chamber. The feces sampling device is simple in structure and convenient to use, facilitates a user in effective controlling of a sampling amount during feces sampling and enables the feces sample to be conveniently and rapidly dissolved into a buffer, thereby obtaining more accurate examination results.

Owner:CREATIVE BIOSCIENCES (GUANGZHOU) CO LTD

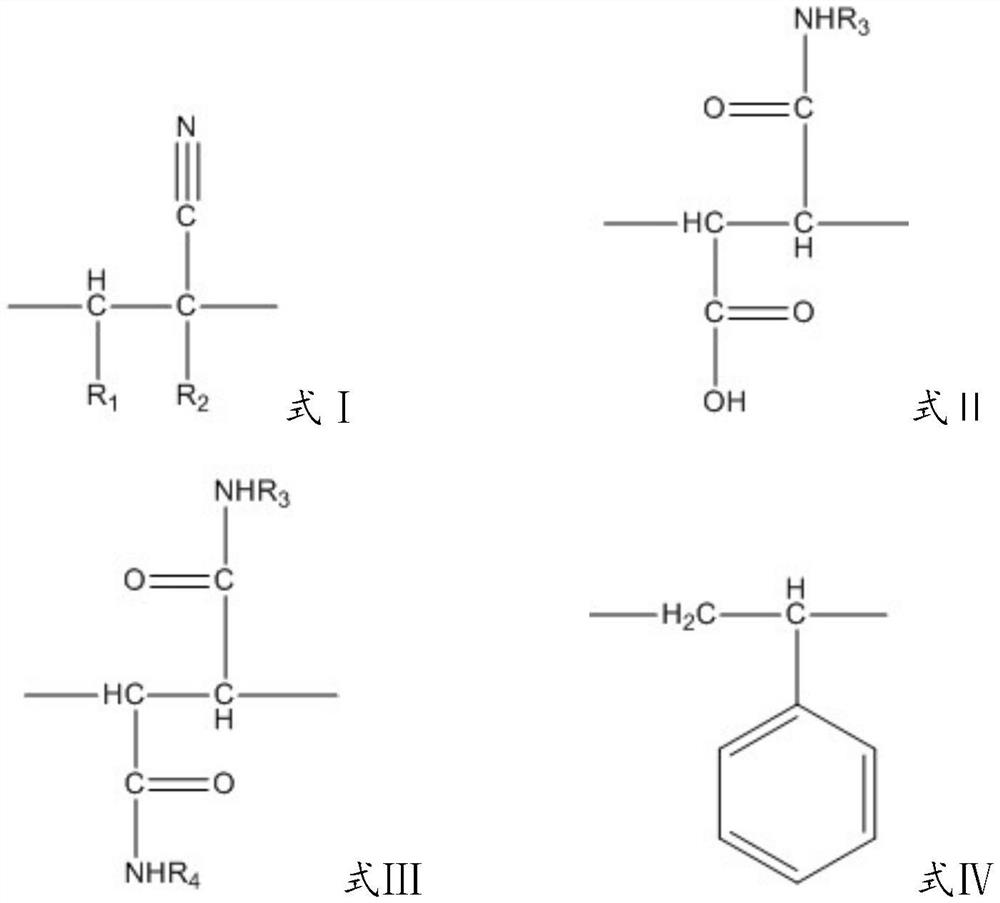

Polymer for crude oil pour point depressing and preparation method and application thereof

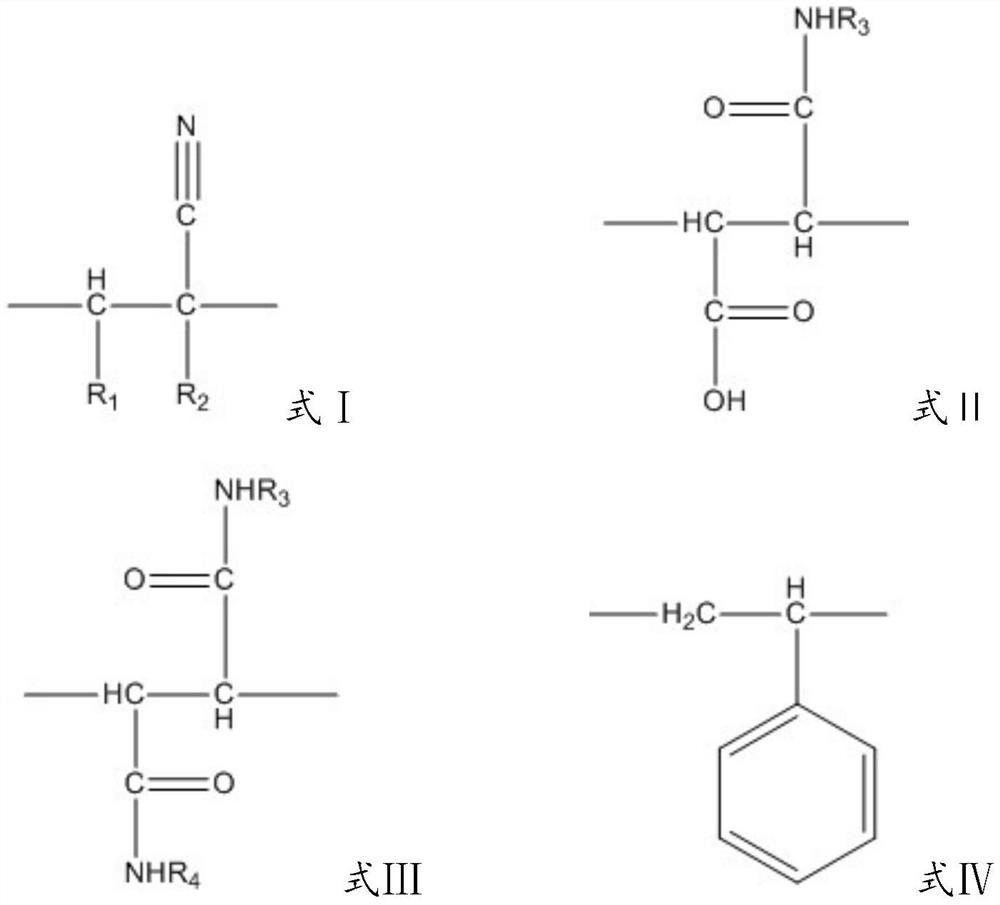

ActiveCN113444190AIncrease the degree of branchingLowering the freezing pointDrilling compositionPolymer scienceStructural unit

The invention discloses a polymer for crude oil pour point depressing and a preparation method and application thereof. The polymer comprises a structural unit A, a structural unit B and a structural unit C, wherein the structural unit A is a structural unit with the structure represented by a formula I, the structural unit B is a structural unit with the structure represented by a formula II or a formula III, and the structural unit C is a structural unit with the structure represented by a formula IV; and on the basis of the weight of the polymer, the weight percentage content of the structural unit A is 5%-25%, the weight percentage content of the structural unit B is 40%-85%, and the weight percentage content of the structural unit C is 10%-35%. The fumaric acid polymer in the polymer is good in rigidity and uniform in polar part distribution, and the long-chain structure of the fumaric acid polymer can act with wax crystals in the high-solidification-point crude oil; the amide structure is high in polarity, and the wax crystal structure can be better adjusted; and polar groups act with colloid and asphaltene in the high-solidification-point crude oil, and the solidification point of the crude oil is reduced.

Owner:DESHI ENERGY TECH GRP CO LTD +1

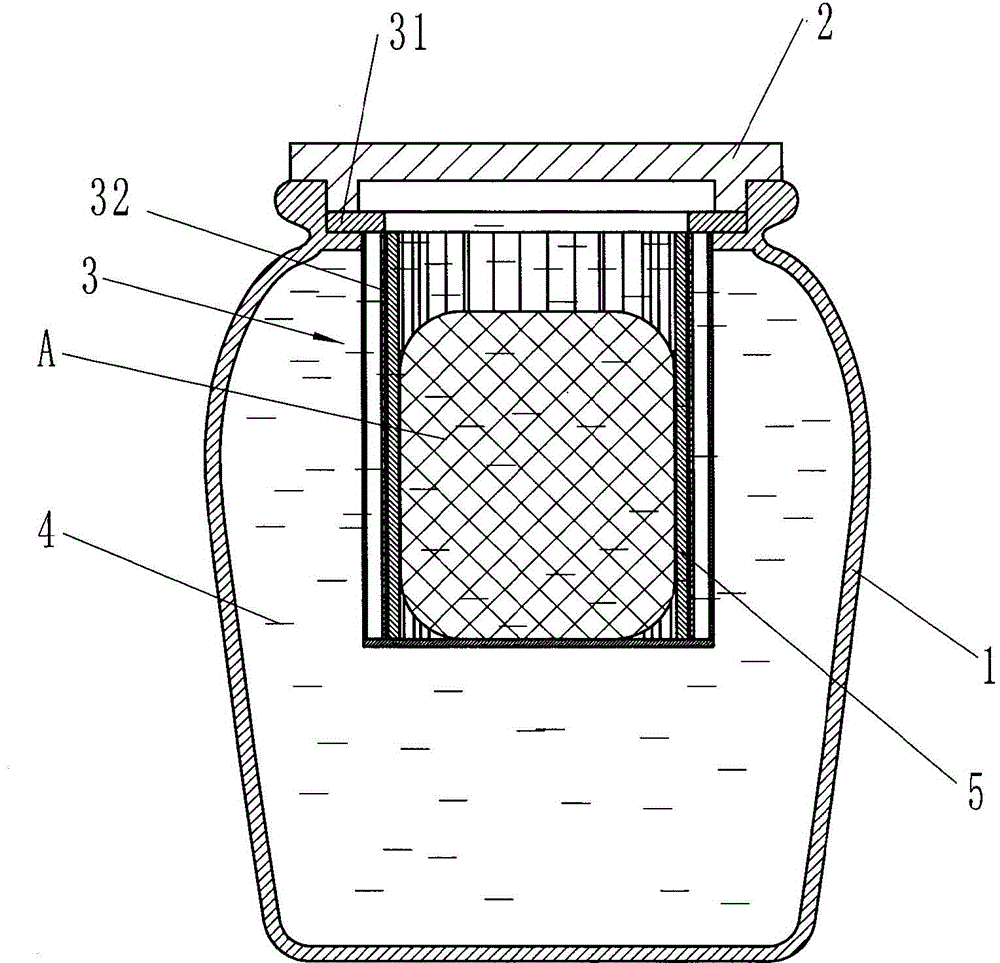

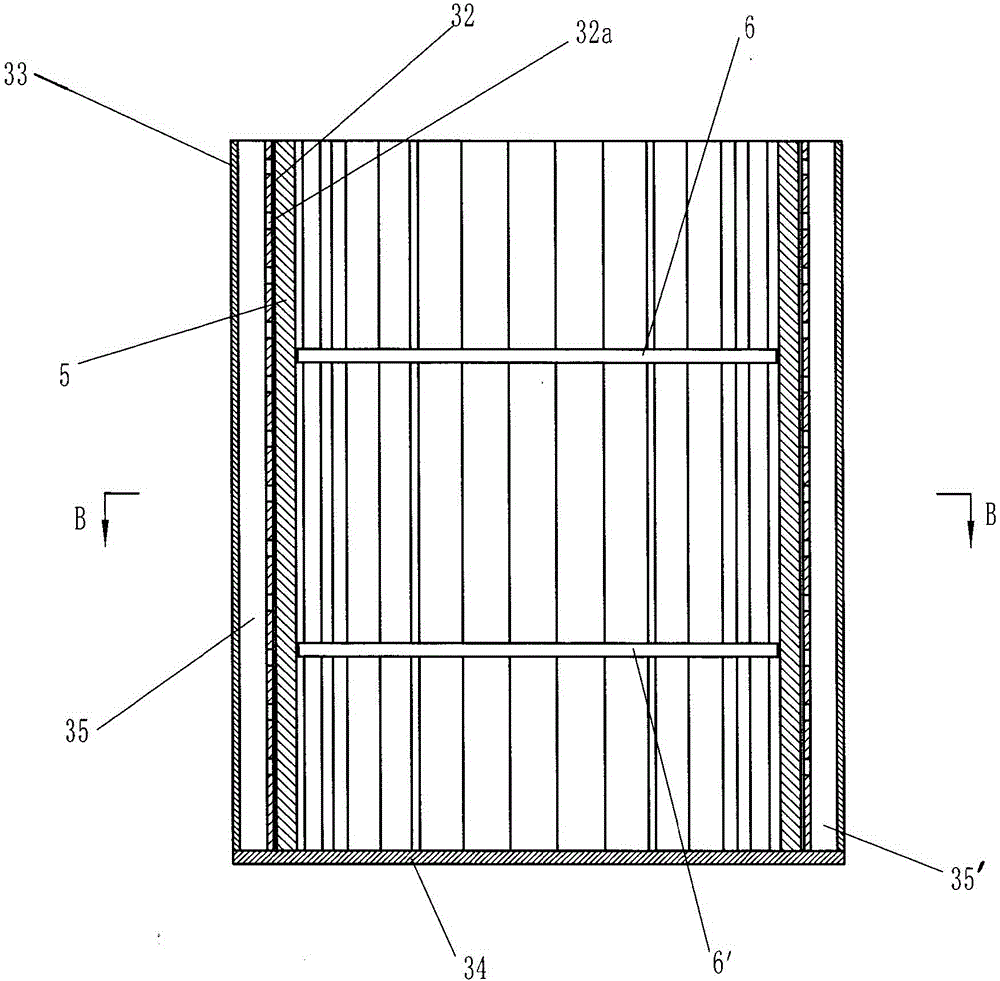

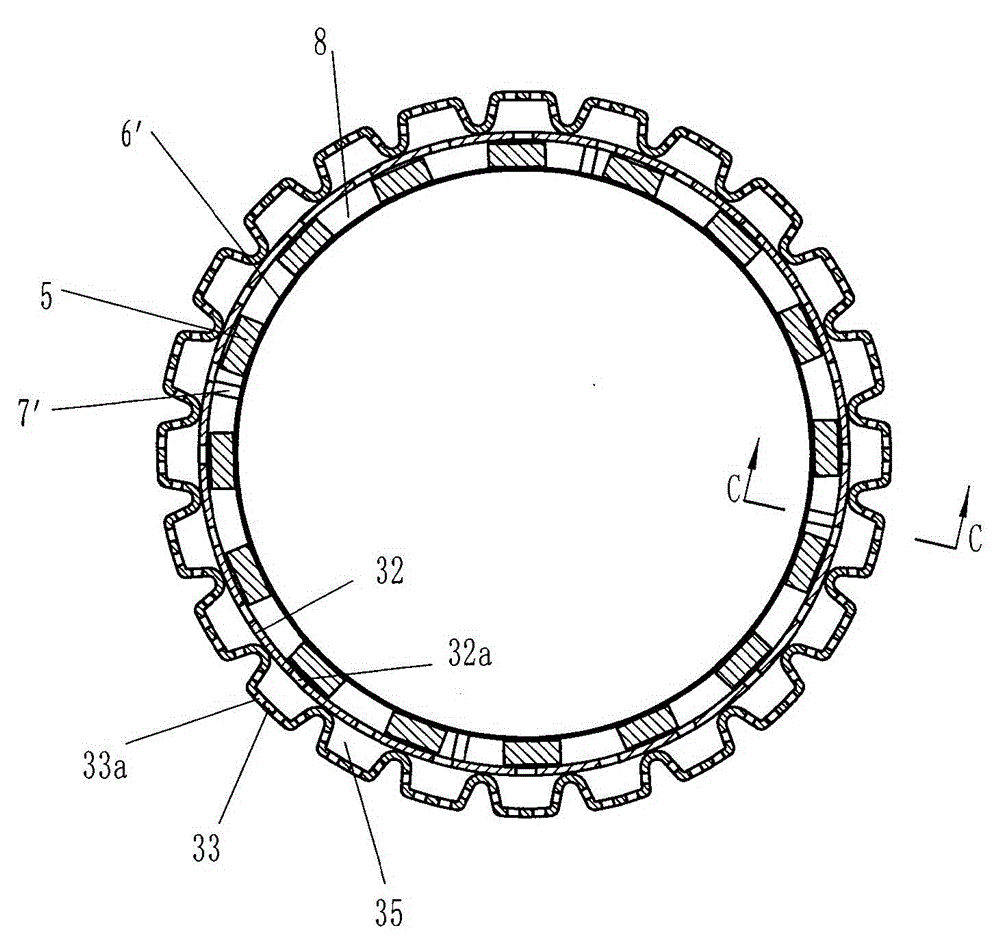

Spirit jar used for preparing white spirit with oak fragrance

ActiveCN104859918AEasy to collectImprove the extraction effectRigid containersInternal fittingsLiquid mediumEngineering

A spirit jar used for preparing a white spirit with an oak fragrance is provided with a ceramic jar body for containing the white spirit, a jar lid and multiple oak strips, and a feed liquid medium generator is arranged in the ceramic jar body and is provided with a boss, a cylinder, multiple protrusive bumps, a bottom plate, an upper check ring, a lower check ring, an upper connecting body and a lower connecting body. The oak strips are inserted into gaps formed by the upper check ring, the lower check ring and the inner wall of the cylinder, the oak strips are arranged on the bottom plate and limited by the upper check ring, the lower check ring and the inner wall of the cylinder. In this way, the soaking mode belongs to jar-in-jar soaking modes, according to the structure, the oak strips are arranged in the feed liquid medium generator and are completely soaked in the white spirit, the soaking mode of soaking in regions through the cylinder and the multiple protrusive bumps is adopted in the feed liquid medium generator, soaking is uniform, and the digestion effect is better; an operator can take out the oak strips out of an end opening of the jar body, the oak strips are easy to replace, and the spirit jar is simple and practical in structure and reduces cost.

Owner:李红军

Pond aerator without external power source

InactiveCN109588365AAchieve continuous oxygenationReduce consumption costPisciculture and aquariaBogieCam

The invention discloses a pond aerator without an external power source and aims to solve the problems that existing aeration devices are higher in cost and lower in service life and need continuous electric energy consumption. The device comprises a floating ring, a bogie, an end cam, a sliding rod, a rotating disc, a main rotating shaft, an air sealing block, aeration blades, an air following plate and an air stopping block. The bogie comprises a rotating ring and a support frame; the rotating ring and the floating ring constitute a revolute pair; the main rotating shaft is supported on therotating ring; the air following plate is fixed on the support frame; the rotating disc comprises a blade pillar and a sliding rod disc; n aeration blades are arranged on the blade pillar in a hollowmanner; multiple aeration holes are formed in the aeration blades; the work contour of the end cam comprises a push-out section, a transition section and a retraction section; n sliding rod through grooves circumferentially and uniformly distributed on the sliding rod disc are formed in the sliding rod disc. The device can realize continuous aeration of pond water under drive of wind instead of external electric power.

Owner:尚钰翔

Manufacturing method of molybdenum or vanadium oxide briquetting for steelmaking alloying

Owner:SHIJIAZHUANG IRON & STEEL +1

Control method for steel tapping slag condition of high-carbon and high-alloy steel 90t converter

ActiveCN113699314AIncrease temperatureGuaranteed to meltProcess efficiency improvementSlagMolten steel

The invention discloses a control method for the steel tapping slag condition of a high-carbon and high-alloy steel 90t converter. The control method comprises the following steps that (1) during steel tapping alloying, a deoxidizing agent, slag charge, carbon powder, alloy and slag charge are added in sequence; (2) alloy baking is performed, specifically, the alloy is added into an alloy baking furnace to be baked in advance before converter smelting, it is guaranteed that the alloy becomes red during steel tapping, and the alloy temperature is 400+ / -50 DEG C; (3) steel tapping slag charge is processed, specifically, the alloy and the slag charge are added in batches according to different time periods; the amount of slag added in the steel tapping process is 4.5 kg / t-5.0 kg / t; (4) bottom blowing system control of a steel tapping steel ladle is performed, specifically, at least two bottom blowing ventilation chambers are opened in the steel tapping process, and bottom blowing is conducted through the single ventilation chamber after steel tapping is finished; and (5) the slag charge is supplemented when the temperature is increased to 1520-1550 DEG C after LF refined molten steel arrives at the station, and the dosage of the slag charge is 4.0 kg / t-4.5 kg / t. According to the method, fluorite does not need to be added for slagging, the dosage of a slagging agent and the power consumption are reduced, the refining time is shortened, and meanwhile, the cost is saved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Making method of pork stick with unique flavor

The invention discloses a making method of a pork stick with a unique flavor. The making method comprises the following production steps of: mixing to prepare a seasoning for later use; mixing to prepare auxiliary materials for later use; removing skin and fat of fresh pork ham, eliminating bones, trimming and shaping; mincing the pork ham after trimming into minced meat through a meat mincing machine; adding the seasoning into the minced meat, rolling and kneading in a vacuum rolling and kneading machine, then increasing the temperature for continuing rolling and kneading, and then rapidly cooling; adding the auxiliary materials into the minced meat, and continuing rolling and kneading in the vacuum rolling and kneading machine; loading the minced meat after well rolling and kneading into a sausage filler, and extruding the pork stick through a shaping head; placing the extruded pork stick into a drying room for drying till the water content is 23-28%; placing the pork stick after drying into a far-infrared dried meat slice roasting machine for roasting; and cooling the pork stick to normal temperature, then packaging through an automatic packaging machine, and further performingconventional microwave sterilization to prepare a product disclosed by the invention. The pork stick made by the making method disclosed by the invention has the advantages of aromatic flavor, abundant nutrition, good product elasticity, excellent taste and broad market prospects.

Owner:广东真美食品股份有限公司

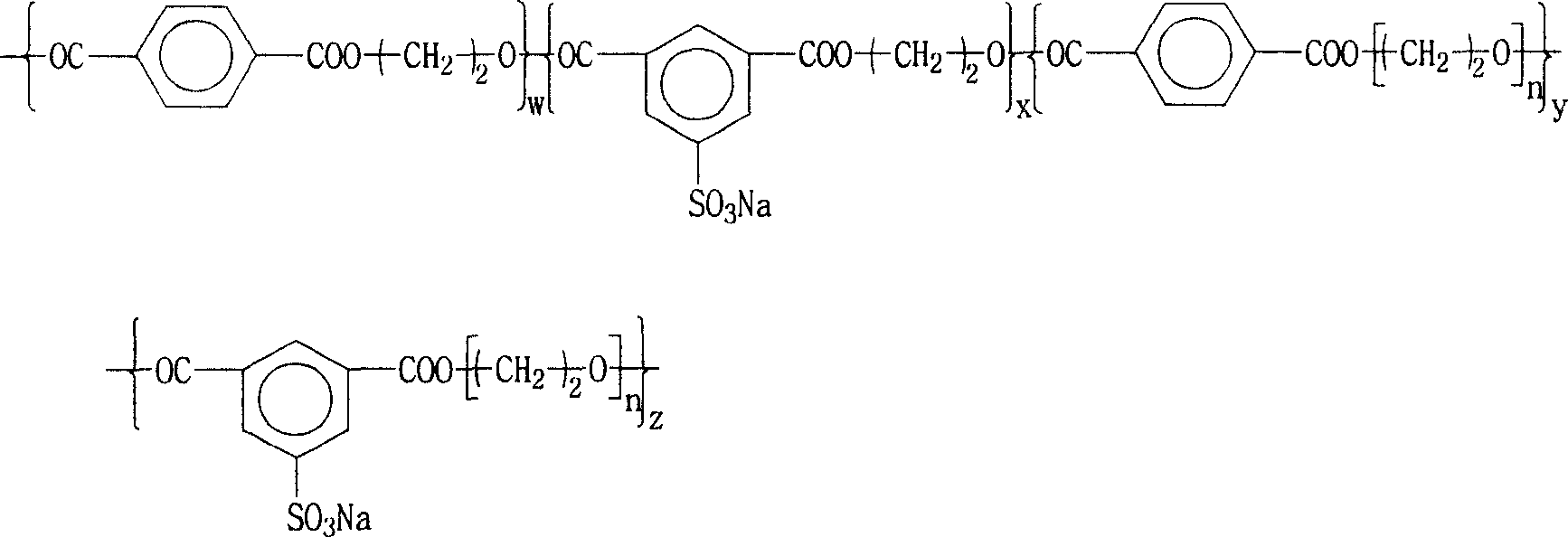

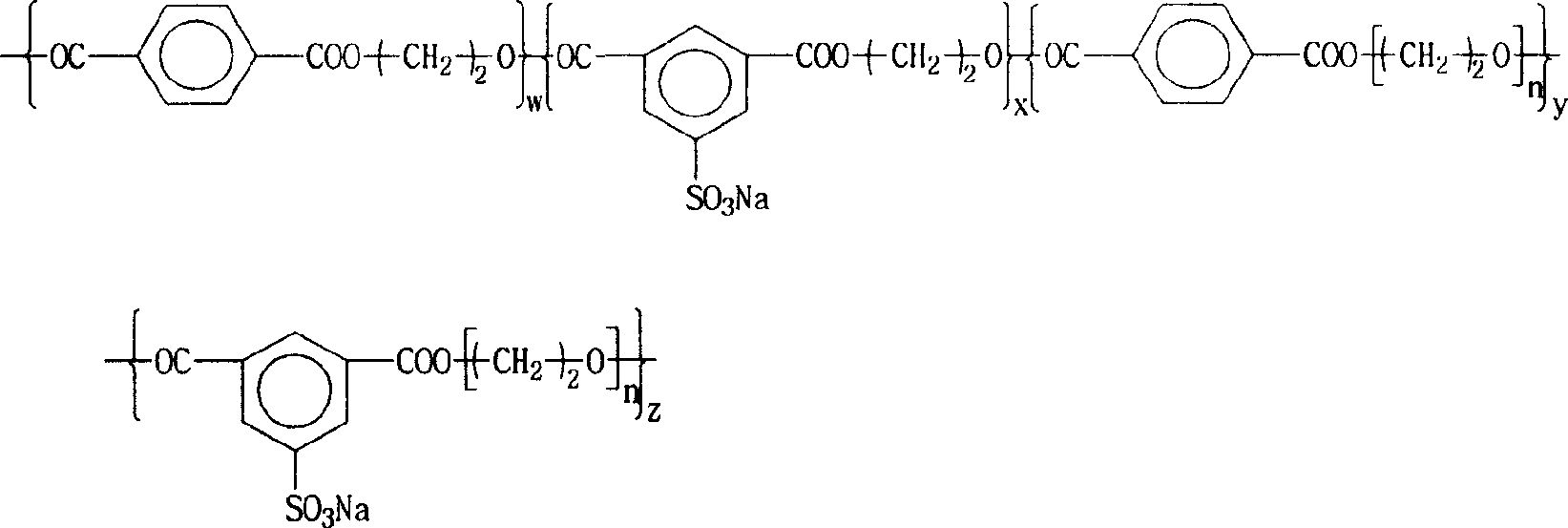

Modified polyester and preparing method thereof

Owner:浙江工程学院

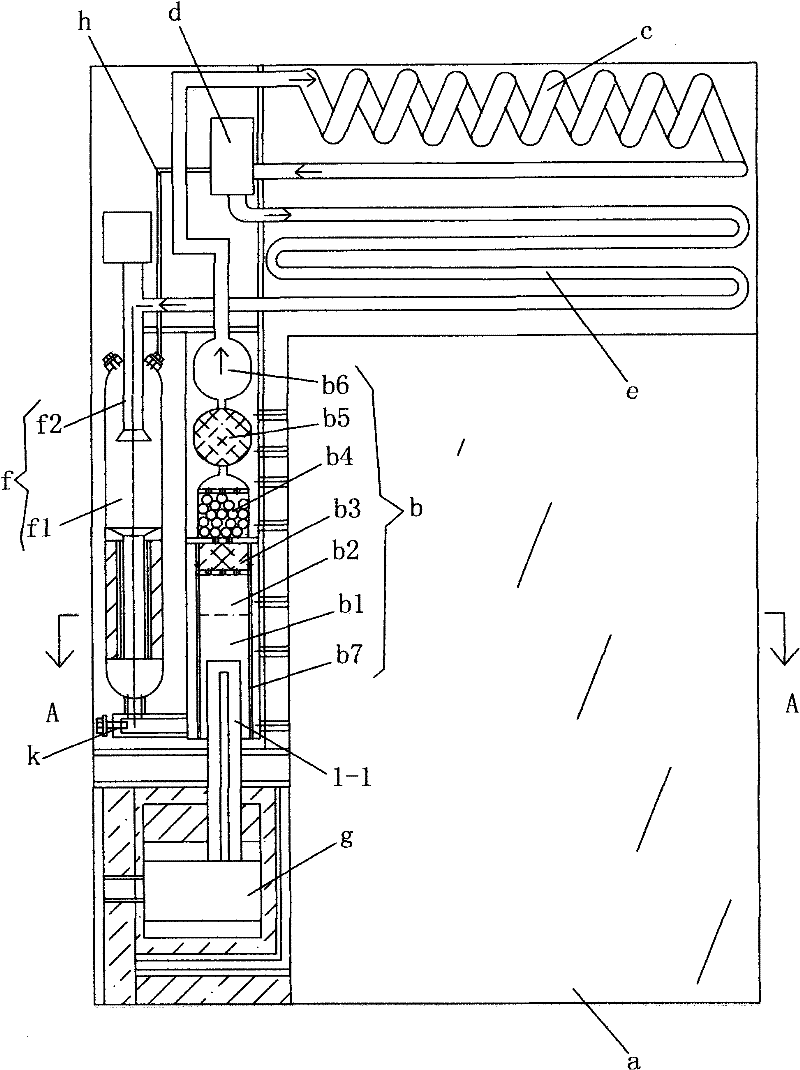

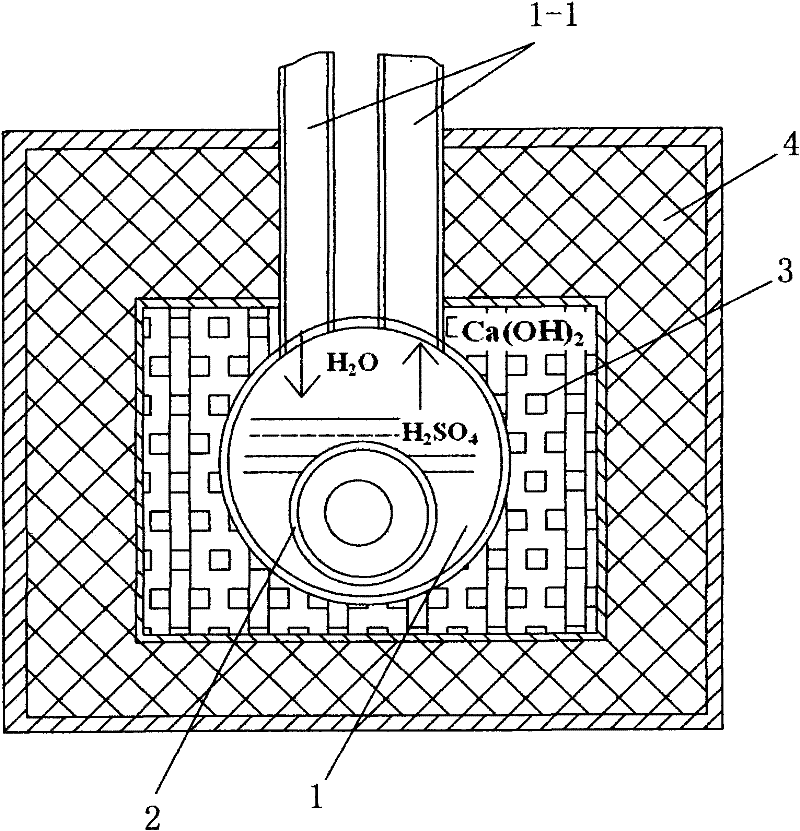

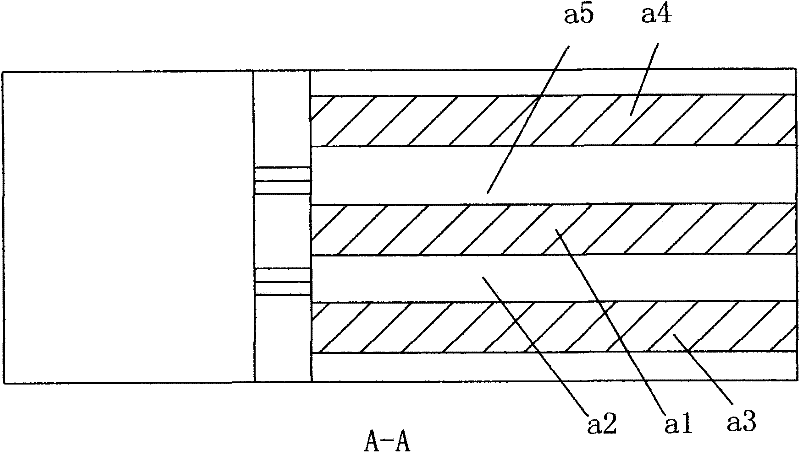

Energy-saving air conditioner

InactiveCN101749818ADissolve quicklySimple structureLighting and heating apparatusAir conditioning systemsEvaporationEngineering

The invention relates to an energy-saving air conditioner which has the characteristics of simple structure, energy saving, long service life, no noise and low using cost. The energy-saving air conditioner comprises an infrared heat absorption device, an ammonia water separating device, a cooling pipe, an expansion valve, a refrigerating pipe and an ammonia water mixing device. The ammonia water separating device is used for utilizing solar heat energy absorbed by the infrared heat absorption device to lead ammonia water solution to be washed by high-valence alcohol after heating evaporation, so as to obtain high-pressure ammonia gas; the cooling pipe is connected with the high-pressure ammonia gas output end of the ammonia water separating device, the expansion valve is connected with the high-pressure ammonia gas output end of the cooling pipe, the refrigerating pipe is connected with a pressure reduction outlet of the expansion valve, the ammonia water mixing device used for dissolving the ammonia gas in water is connected with an outlet of the refrigerating pipe, and an ammonia water solution delivery outlet of the ammonia water mixing device is connected with an ammonia water solution inlet of the ammonia water separating device. When in need of warm getting, the cooling pipe is arranged indoors and the refrigerating pipe is arranged outdoors.

Owner:林奇新

Self-regulation type ink box based on annular crushing

ActiveCN110561917AImprove the rotation effectReduce resistancePrintingEngineeringMechanical engineering

Owner:诸暨市凯腾广告设计有限公司

A method to improve the efficiency of anaerobic sludge granulation

ActiveCN107352647BClear relationshipPromote formationWater treatment compoundsBiological treatment regulationHomoserineOrganic synthesis

The invention discloses a method for improving the anaerobic sludge granulation efficiency, and belongs to the field of organic waste water treatment. The method for improving the anaerobic sludge granulation efficiency is provided for the problems that the anaerobic granular sludge culture circle is long, the granule stability is poor, and the culture cost is high in the prior art. The method comprises the steps that an appropriate number of organically synthesized acyl-homoserine lactone (AHL) signal molecules are added into the bottom of an EGSB reactor used for anaerobic sludge granulation culture periodically and mixed with anaerobic sludge, the addition cycle is the same as the hydraulic retention time, and the advantages that the anaerobic sludge granulation efficiency is high, the cost is low, the needed granulation time is greatly shortened, the formed granular sludge is good in stability, the structure is simple, and operation is convenient can be achieved.

Owner:NANJING UNIV

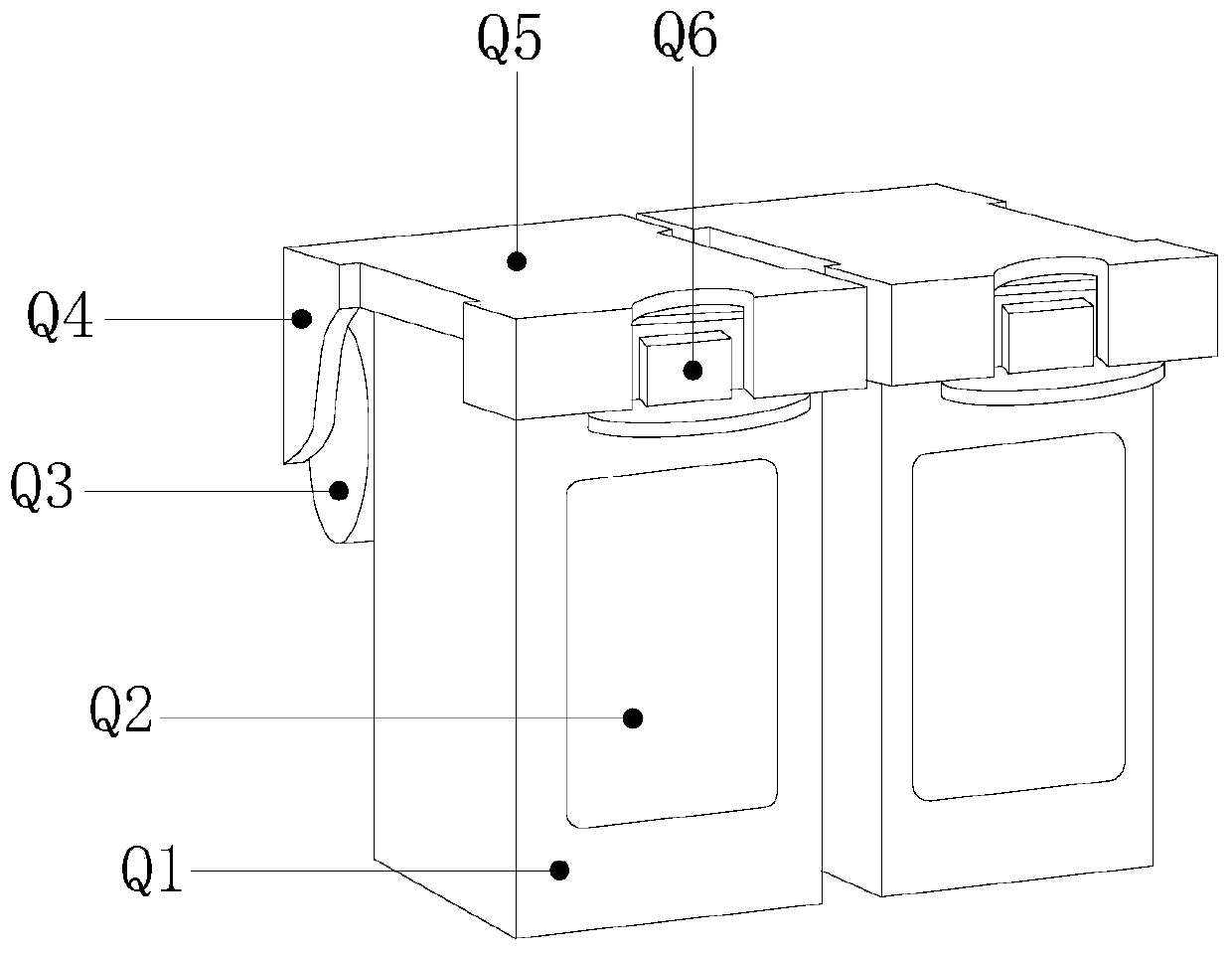

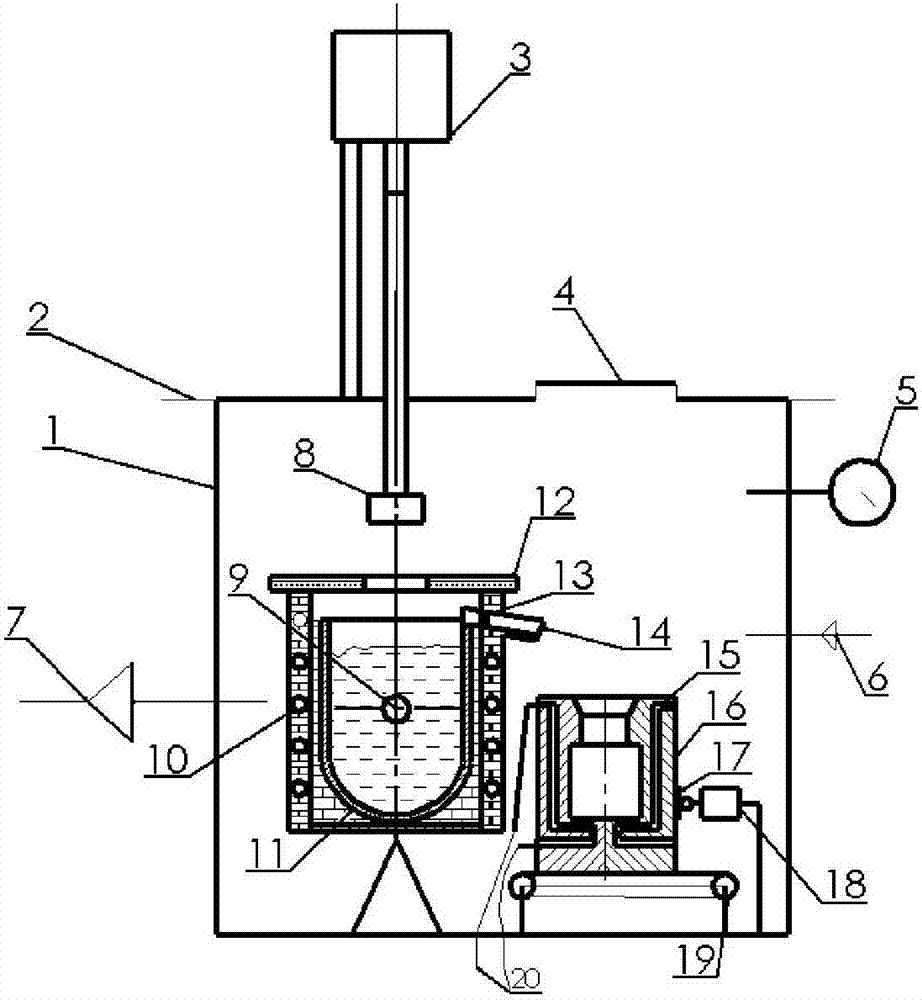

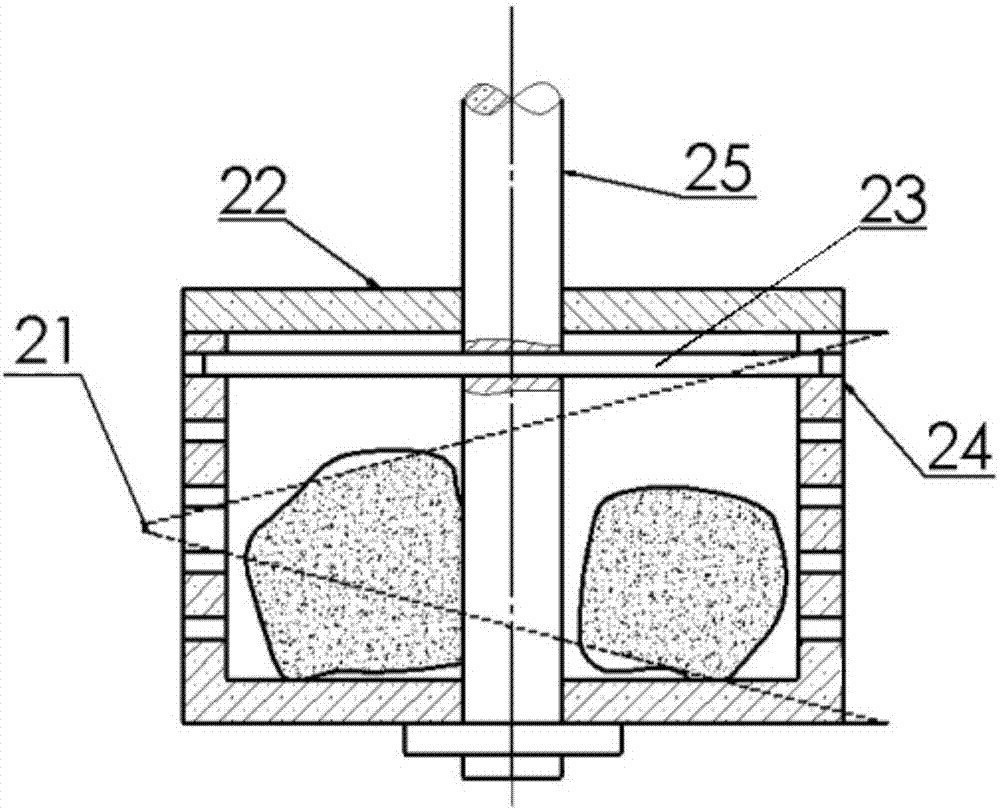

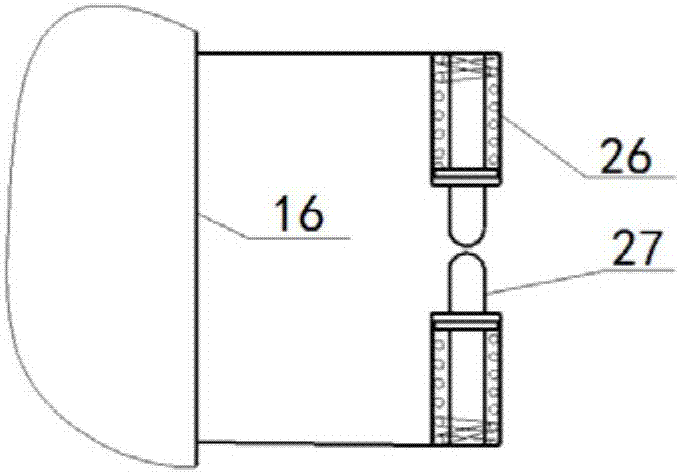

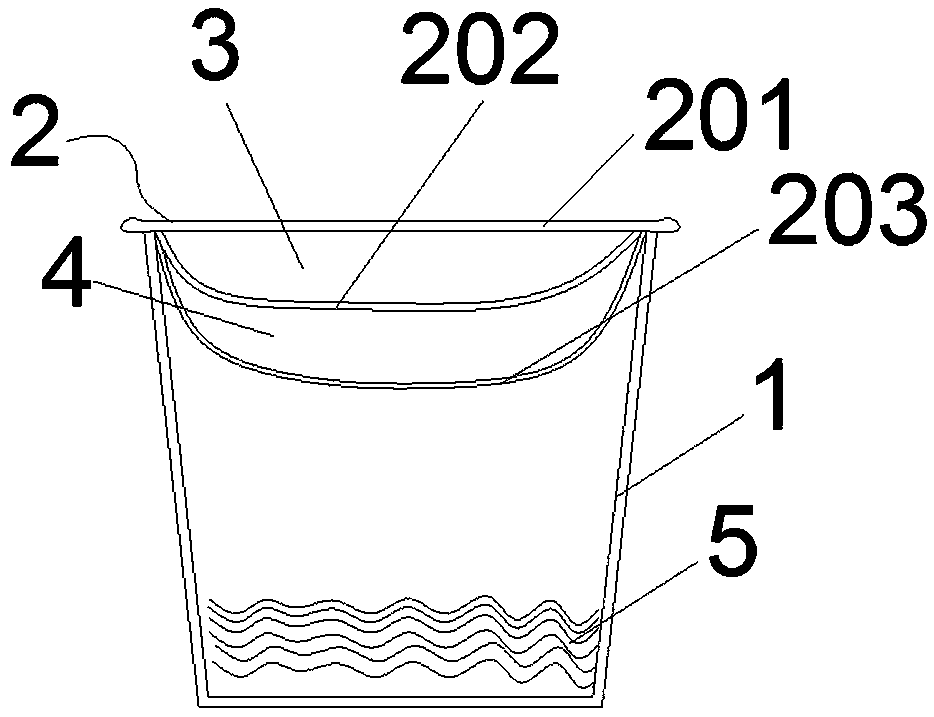

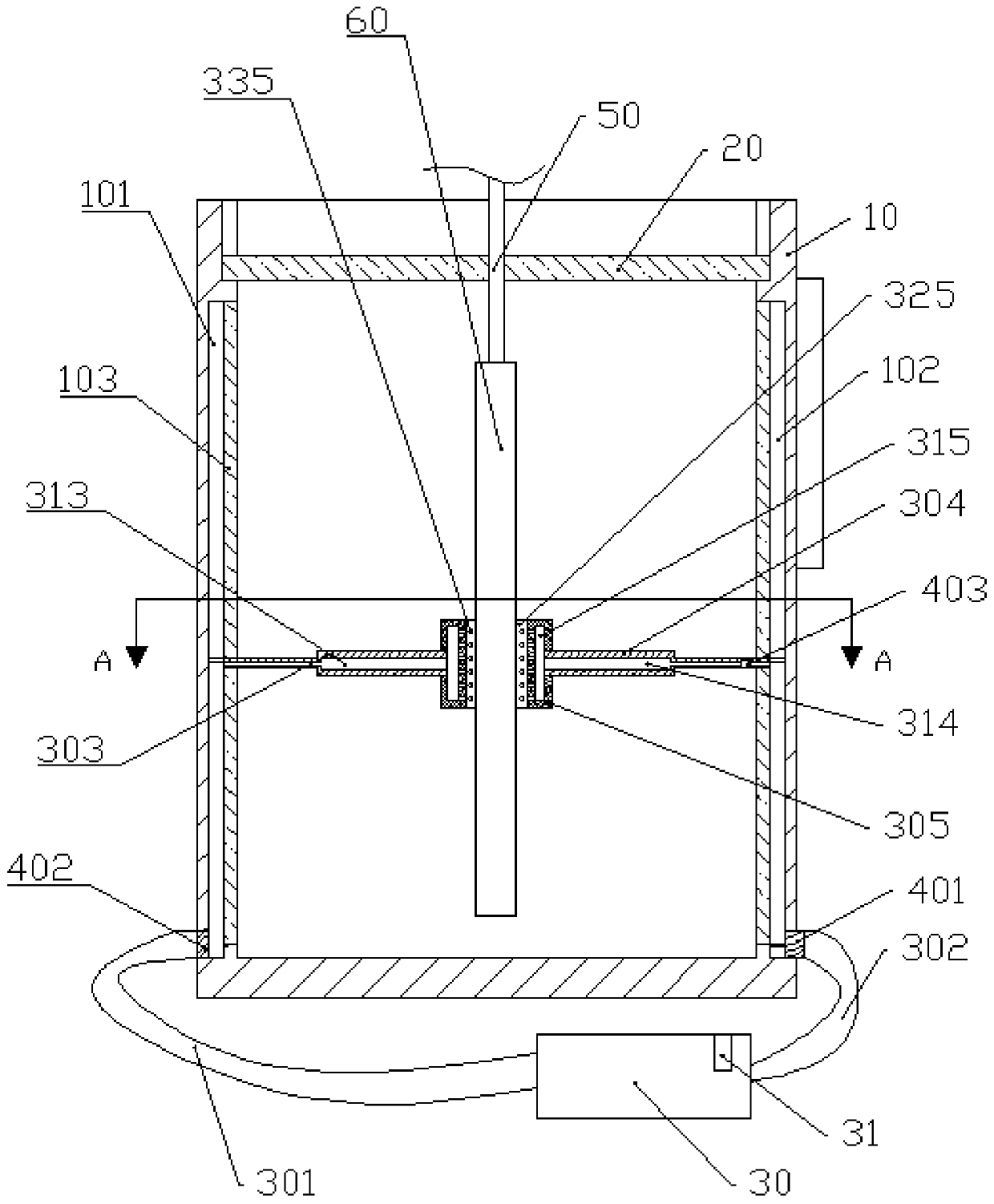

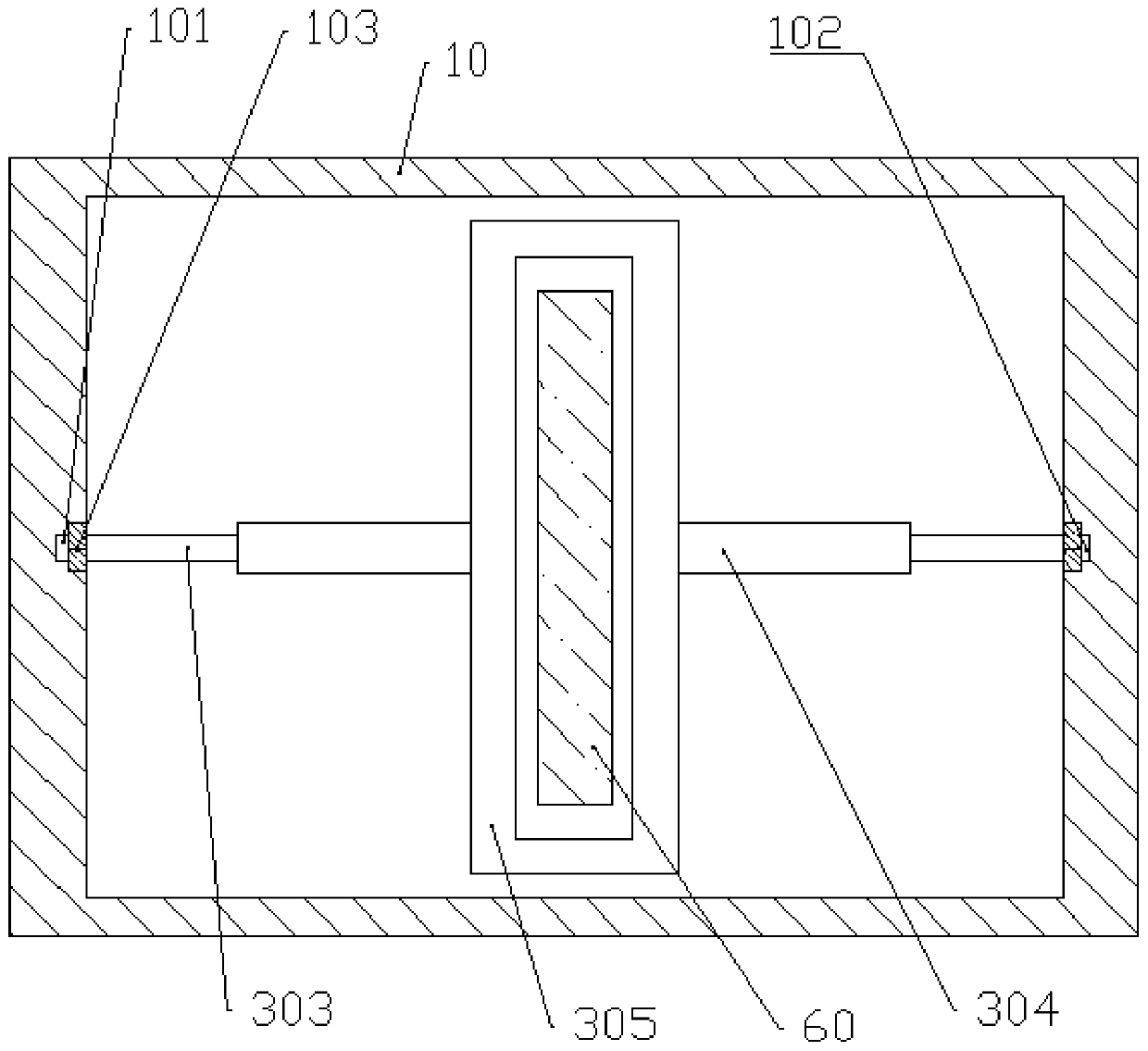

A kind of preparation and forming method of nickel-based hydrogen storage alloy containing rare earth magnesium boron

The invention relates to equipment and a method for preparing a nickel-base hydrogen storage alloy containing rare-earth, magnesium and boron and belongs to the field of smelted alloys. The equipment comprises a smelting-pouring tank, a lifting-stirring mechanism, an induction smelting furnace, a crucible, a pouring mold, a pouring mold driving device, a slide and a cooling water circulating system, wherein the smelting-pouring tank communicates with a shielding gas injection device and a vacuum pumping device. After an alloy is smelted, shielding gas is injected into the smelting-pouring tank under the vacuum condition and is pressurized, magnesium blocks are added under the high pressure and are quickly stirred, after melt is prepared, the pouring mold is cooled, and pouring is performed. The alloy prepared with the equipment and the method is stable in quality, compact in structure and small in composition segregation, requirements of further processing are met, the equipment is easy to popularize and suitable for large-scale production of the nickel-base hydrogen storage alloy containing rare-earth, magnesium and boron, and the material yield is high.

Owner:HENAN POLYTECHNIC UNIV

Thin soup rich in fungus polysaccharide and fruit polysaccharide

InactiveCN108157801AImprove solubilityLow absorption rateNatural extract food ingredientsSolubilityVegetable oil

The invention belongs to the field of preparation of thin soup products, and particularly relates to thin soup rich in fungus polysaccharide and fruit polysaccharide. The thin soup is prepared from the following raw materials in percentage by weight of 10-15% of pholiota nameko enzymolysis extracting solution freeze-dried powder, 2-5% of shiitake mushroom enzymolysis extracting solution freeze-dried powder, 3-6% of hericium erinaceus enzymolysis extracting solution freeze-dried powder, 5-8% of coix seed water extract freeze-dried powder, 2-5% of passion fruit water extract freeze-dried powder,1.5-3% of table salt, 1.0-2.0% of vegetable oil and the balance of concentrated bone soup. The made thin soup is rich in fungus polysaccharide and fruit polysaccharide, is good in solubility in waterand is good in digestive absorption effect.

Owner:张可池

Novel intelligent solar energy storage electric aerator

InactiveCN112806316AHigh degree of automationIncrease dissolved oxygenPisciculture and aquariaImpellerSolar energy storage

The invention discloses a novel intelligent solar energy storage electric aerator. The novel intelligent solar energy storage electric aerator comprises a shell, a photovoltaic panel, a steering engine, a first motor, a second motor, an air pump and an impeller, the photovoltaic panel is fixedly installed at the top of the shell, the side wall of the shell is fixedly connected with one end of a connecting rod, the other end of the connecting rod is fixedly installed on a floating ball, the bottom of the floating ball is fixedly connected with an output shaft of the steering engine, a dissolved oxygen sensor and a fixing frame are fixedly connected to the side wall of the steering engine, a first motor is fixedly installed at the end of the fixing frame, and a propeller is fixedly installed on an output shaft of the first motor. The novel intelligent solar energy storage electric aerator is high in automation degree, can flexibly move and can solve the problems that people need to be on duty for a long time and the aeration area is not uniform; the labor cost is effectively reduced, the aeration efficiency is improved, the self-generating capacity is achieved, the power consumption is small, and the endurance time is longer.

Owner:GUANGDONG OCEAN UNIVERSITY

Multifunctional reversed-phase suspension resistance reducing agent system for shale gas factory-like sand fracturing fluid

PendingCN114686197AThe effect of reducing friction is goodHigh kinematic viscosityDrilling compositionHexamethylenetetramineActive agent

The invention relates to the technical field of resistance reducing agents, and discloses a multifunctional reversed-phase suspension resistance reducing agent system for shale gas factory-like sand fracturing fluid, which comprises an oil phase, a water-soluble monomer, a suspending agent, an initiator, a surfactant A, a surfactant B, a cleanup additive, an anti-swelling agent and clear water, the surfactant A is one or a composition of more of nonylphenol polyoxyethylene ether, span 80 and Tween; the surfactant B is one or a composition of more of alkylaryl polyoxyethylene ether and 12-hydroxystearic acid-polyoxyethylene ether; the surfactant B is one or a composition of more of alkylaryl polyoxyethylene ether and 12-hydroxystearic acid-polyoxyethylene ether; the discharge aiding agent is organic fluorocarbon; the anti-swelling agent is hexamethylenetetramine ammonium chloride. The scheme has the beneficial effects that the resistance reducing agent prepared by adopting a reversed-phase suspension polymerization method is quick in dispersion and dissolution time in water, high in viscosity and low in friction resistance, and can effectively reduce the friction resistance of fracturing construction, reduce the pumping pressure of construction and reduce the safety risk of construction at the same time; the system has discharge aiding and anti-swelling performance, and a discharge aiding agent and an anti-swelling agent do not need to be additionally pumped through a fracturing blender truck during construction.

Owner:四川川庆井下科技有限公司

A kind of tin plating leveling method for circuit board

ActiveCN107937972BUniform thicknessImprove immersionCellsPrinted circuit manufactureTin platingEngineering

The invention relates to the field of circuit board machining methods, and particularly discloses a tin plating leveling method for a circuit board. According to the tin plating leveling method for the circuit board, a tin plating device is adopted, a spraying mechanism in the tin plating device can be used for enhancing the liquidity of an electroplating solution in an electroplating box in the tin plating process, and the electroplating solution on the two sides of the circuit board can be exchanged, so that the electroplating solution in the whole electroplating box is uniform and stable and the electroplating efficiency of the circuit board can be effectively improved.

Owner:重庆市志益鑫电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com