Novel centrifugal misting fan blade

A centrifugal atomization and fan blade technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory atomization effect, slow atomization speed, low separation efficiency of toxic substances and smoke, etc. To achieve the effect of good atomization effect, fast atomization speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

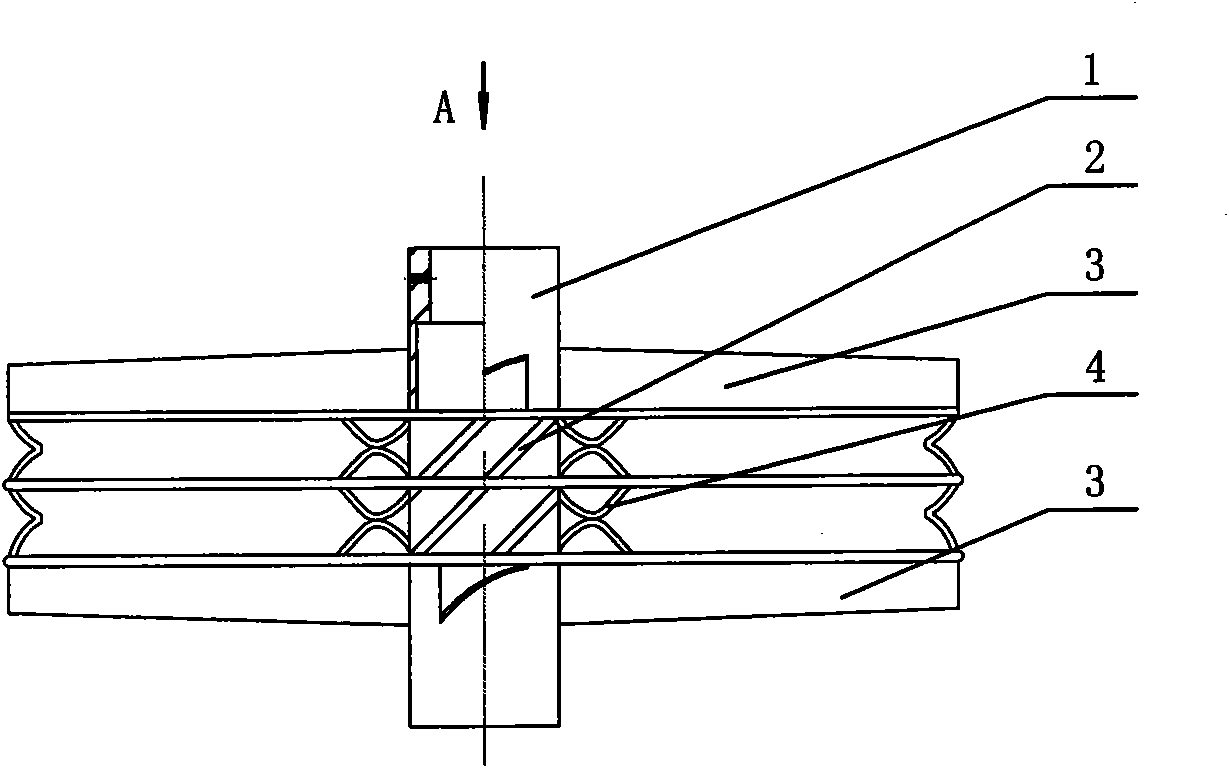

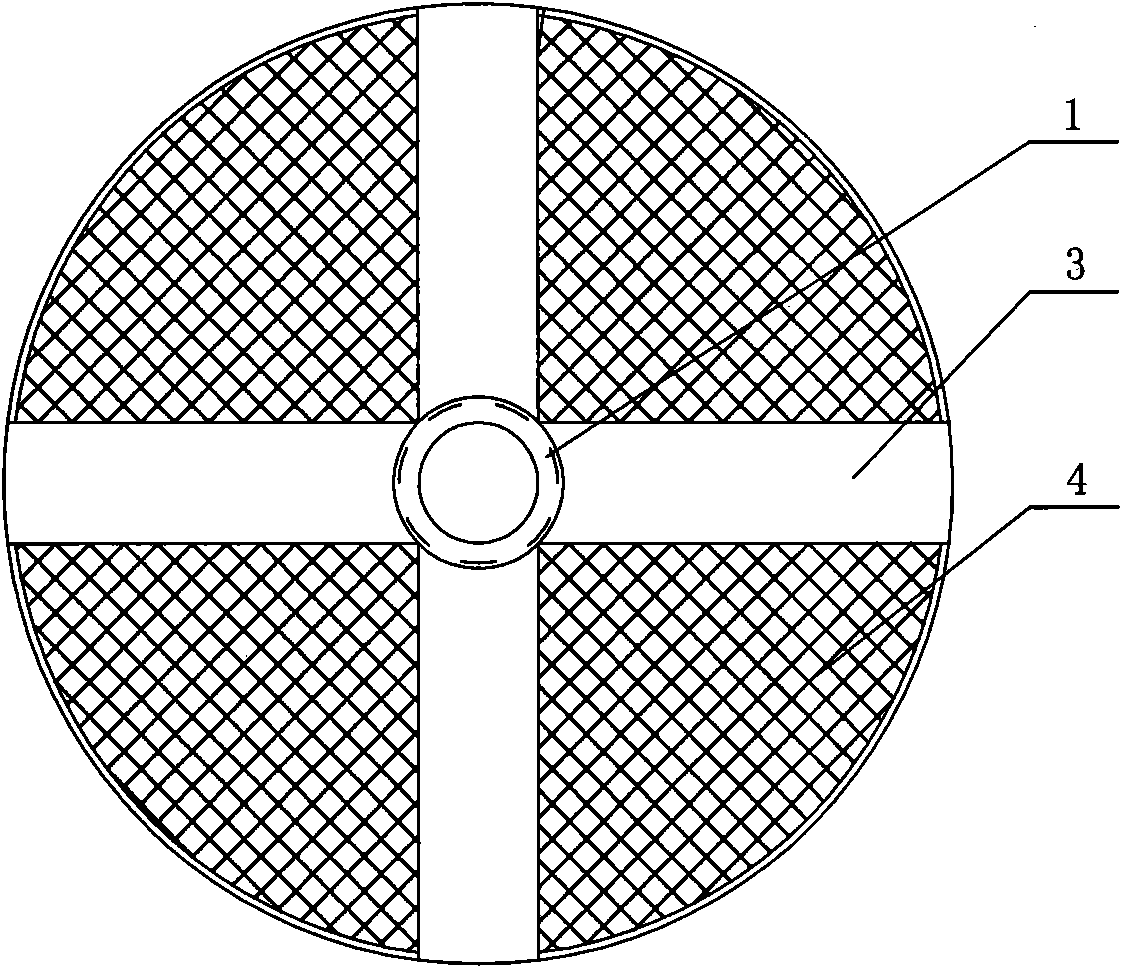

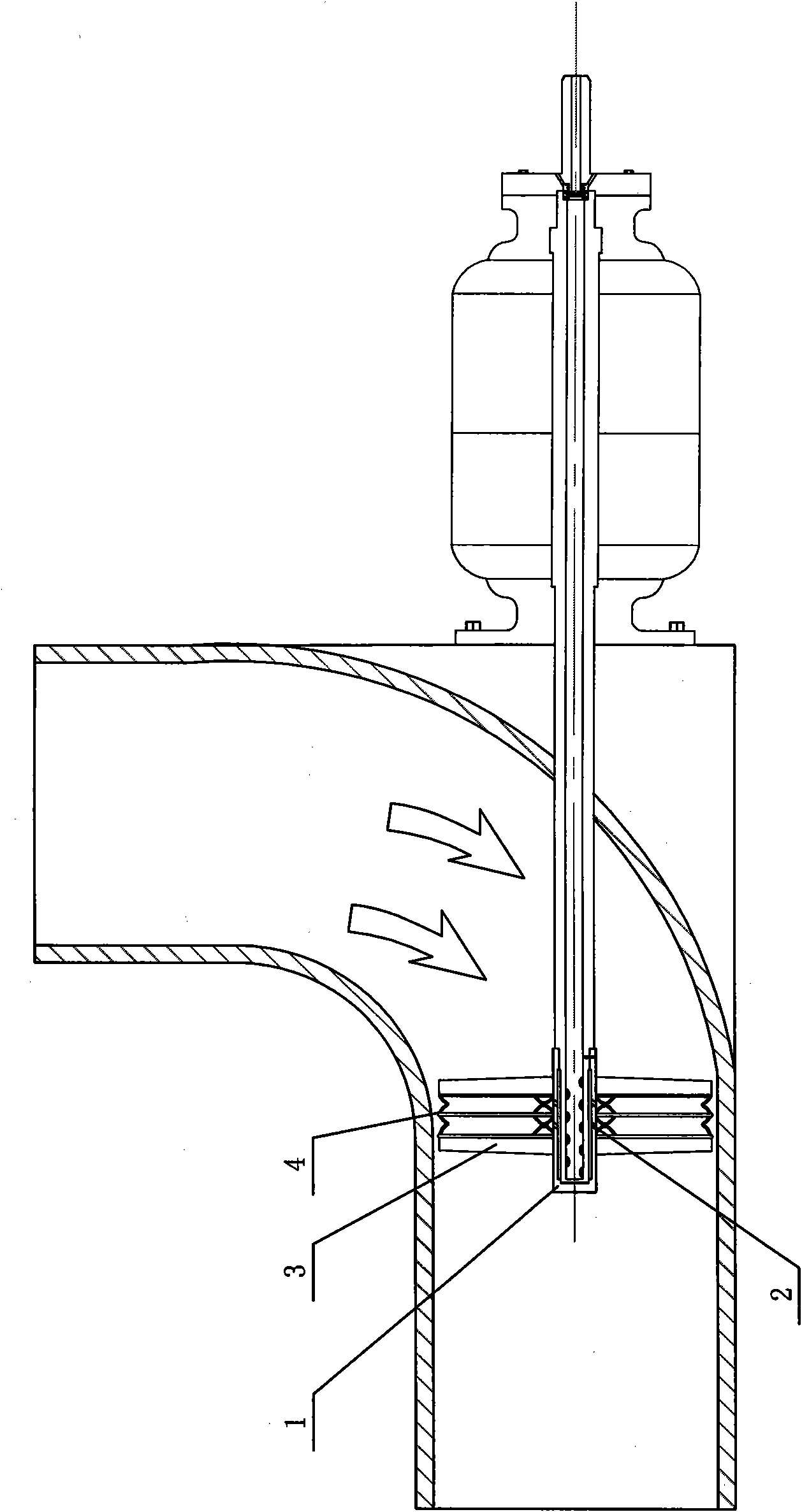

[0013] Such as figure 1 , figure 2 As shown, the present invention is a new type of centrifugal atomizing fan blade, which is mainly installed in the exhaust gas exhaust pipe, including the shaft sleeve 1 connected with the water inlet pipe and the fan blade 3 fixed on the shaft sleeve 1, and the fan blade 3 There are two front and rear sets on the shaft sleeve 1, and the fan blade 3 includes 3 or 4 inclined blades uniformly distributed along the shaft sleeve. An atomizing net 4 is installed between the two blades 3, and the atomizing net 4 is a disc-shaped steel wire net, which is made by kneading one or more steel wires into a ball and then pressing them into a disc shape. The water inlet pipe is driven by a motor and can rotate at a high speed, and a plurality of water spray holes are opened on the front side wall of the water inlet pipe. The shaft sleeve 1 is socketed with the front end of the water inlet pipe, and is fixed with the water inlet pipe by positioning pins,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com