A kind of preparation and forming method of nickel-based hydrogen storage alloy containing rare earth magnesium boron

A technology for hydrogen storage alloy and rare earth magnesium, which is applied in the field of alloy smelting, can solve the problems of easy volatilization of magnesium and high vapor pressure of magnesium, and achieve the effects of controllable magnesium composition, small composition segregation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

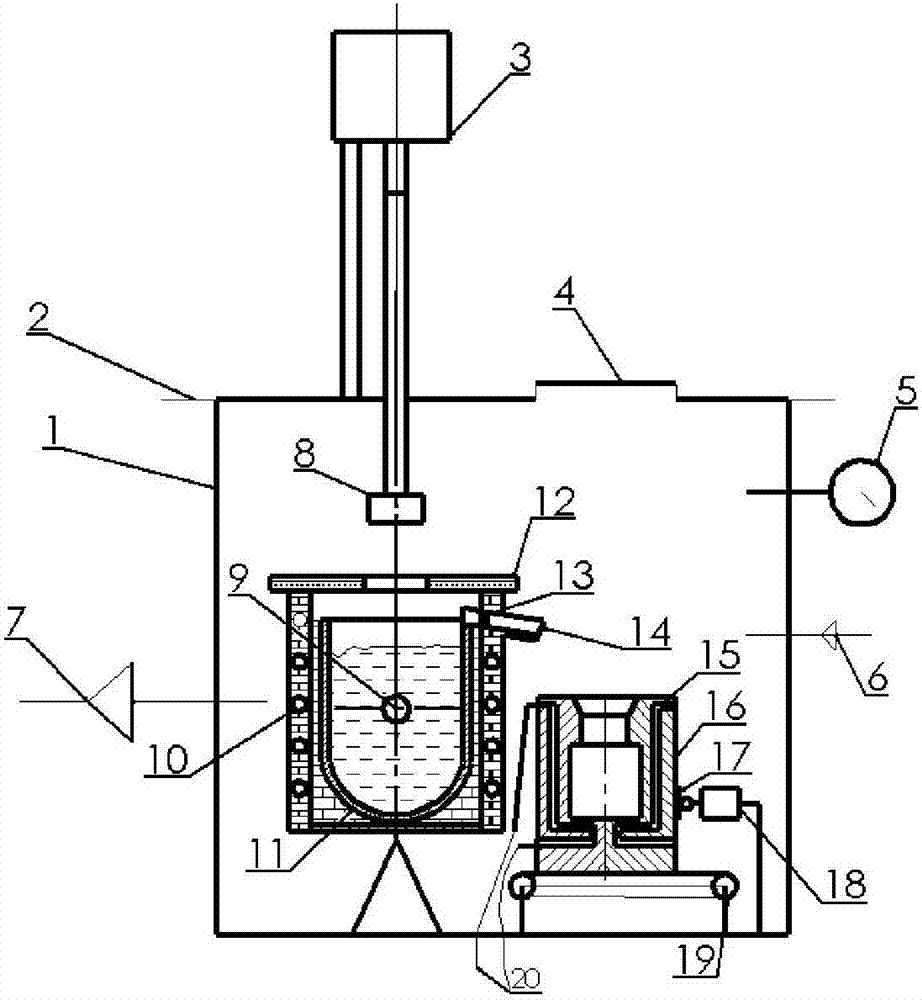

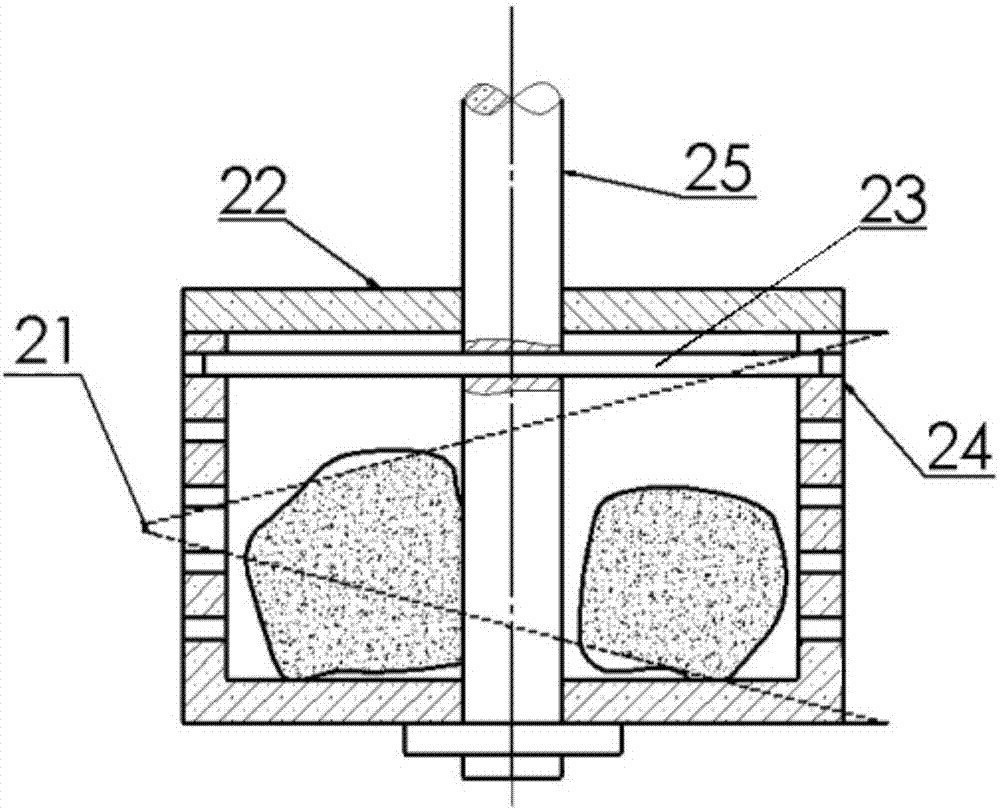

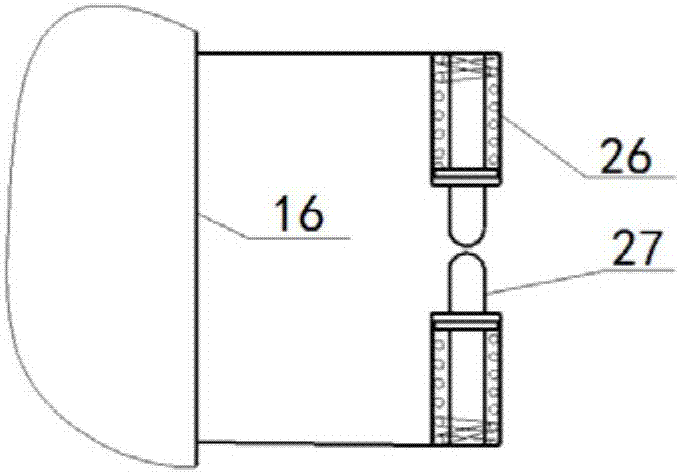

Method used

Image

Examples

Embodiment 2

[0046] In this example, the same equipment as in Example 1 was used to prepare the nickel-hydrogen alloy. Only in this example, press La 4-x RE x MgNi y-z B z For batching, RE is Ce, Pr, B is Zn, x=1.7, y=17.1, z=3.5, and the ingredients are energized and melted to obtain the corresponding melt; after the added ingredients are completely melted, the melt is evacuated; When the vacuum degree reaches 7.8Pa, inject protective gas, the pressure rises to 1670Pa, and at the same time, the temperature of the melt drops to 1305°C; add magnesium blocks to the melt, and reversely stir the melt at a speed of 170 rpm Minutes, forward stirring at intervals of 3 minutes, and reciprocating for 13 minutes; increase the speed to 350 rpm, reverse stirring at intervals of 5 minutes, reciprocating for 30 minutes, and the melt preparation is completed; keep the obtained melt at 1370 ° C and wait for pouring ; Cool the pouring mold and pour it. The alloy prepared after pouring has compact stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com