Self-regulation type ink box based on annular crushing

A self-adjusting, ink cartridge technology, applied in printing and other directions, can solve problems such as water evaporation, ink residue, and ink residue content differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

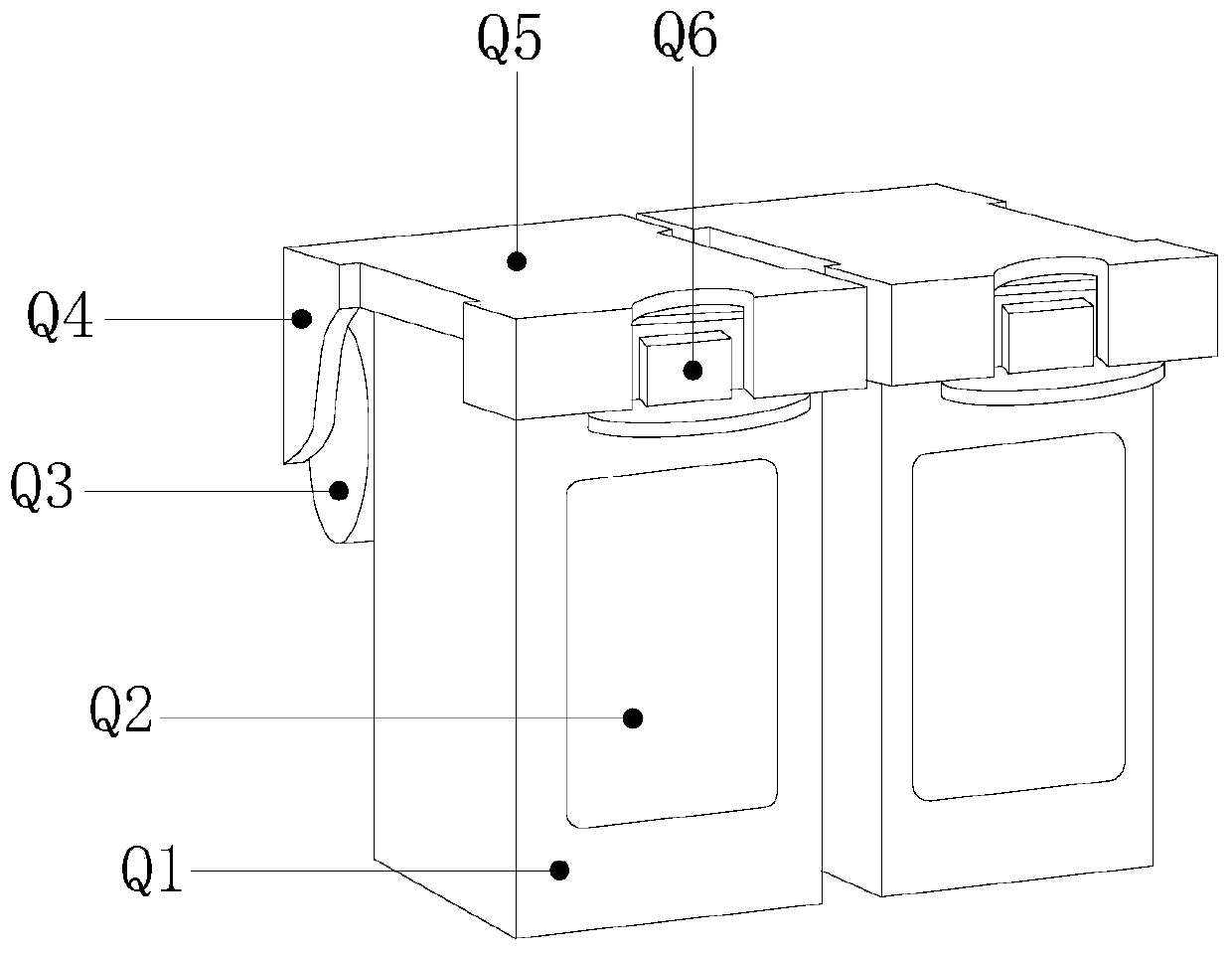

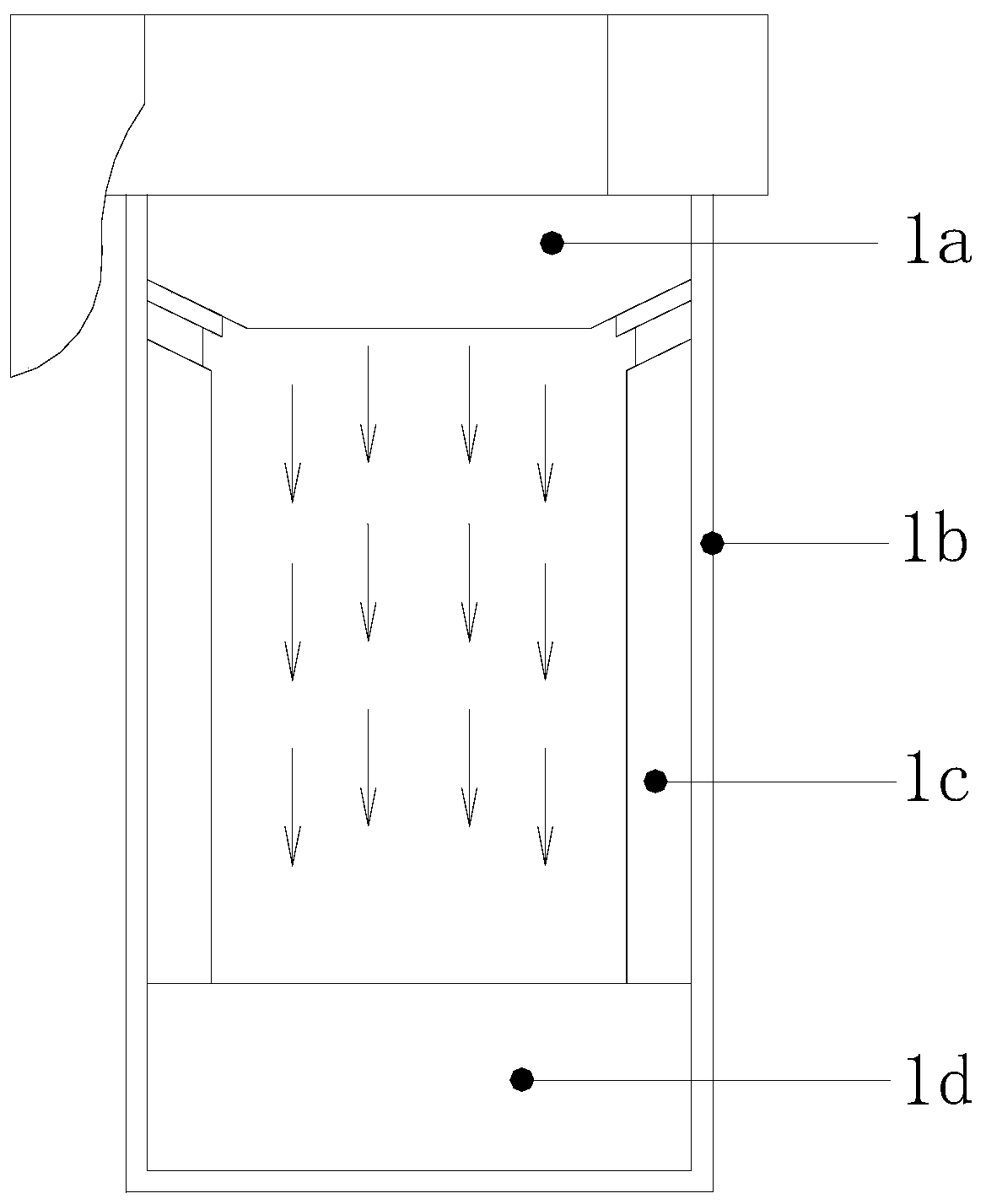

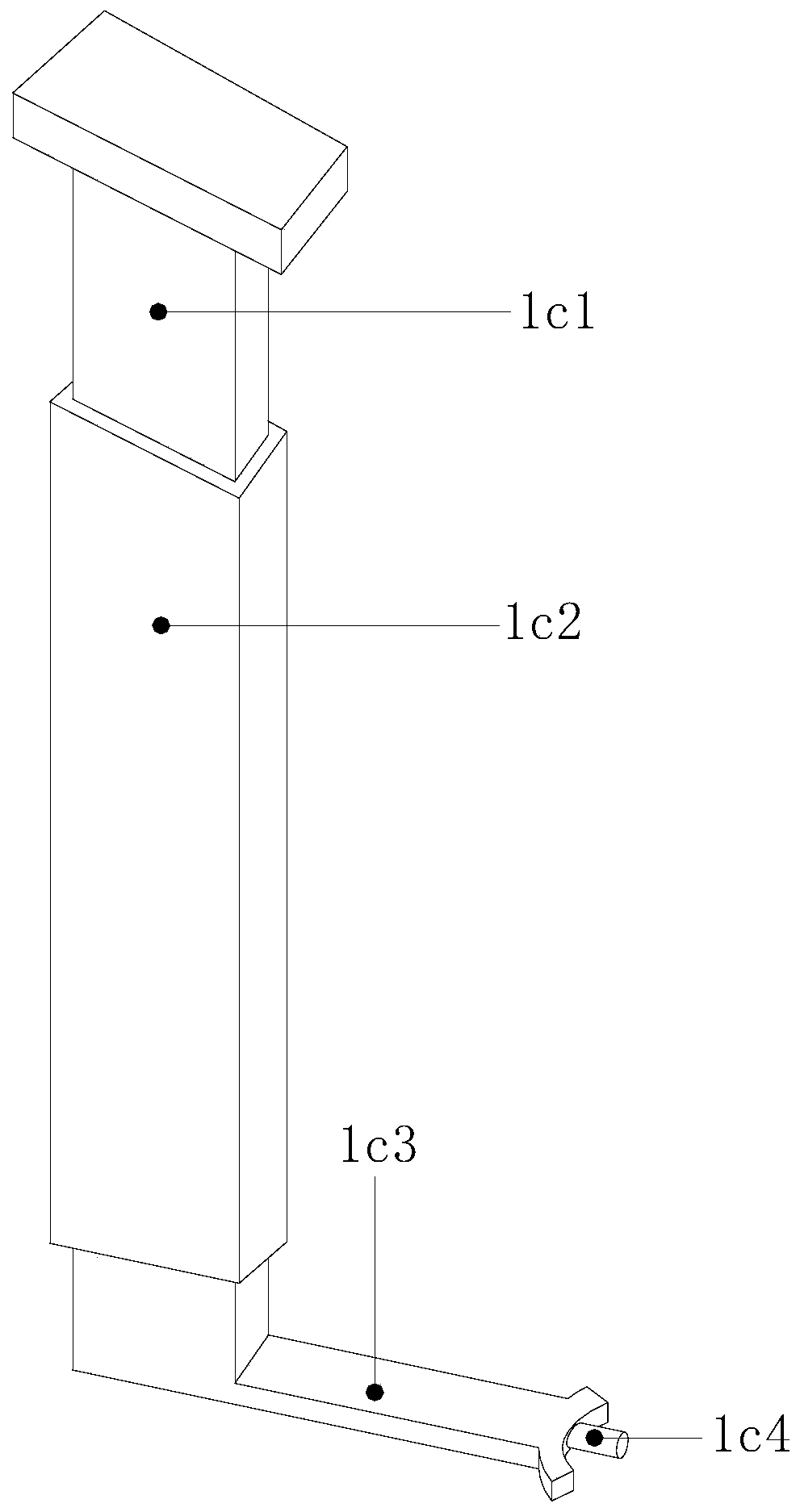

[0029] see Figure 1-Figure 6 , the present invention provides a self-adjusting ink cartridge based on circumferential crushing, its structure includes an ink cartridge main body Q1, a logo groove Q2, an assembly buckle Q3, a flip cover seat Q4, an ink cartridge top cover Q5, and a positioning foot Q6. The feet Q6 are arranged on the top of the front end of the ink cartridge main body Q1 and are of an integrated structure. The top of the rear end of the ink cartridge main body Q1 is provided with an assembly buckle Q3 and are of an integrated structure. The top cover of the ink cartridge Q5 is installed on the On the top of the main body Q1 of the ink cartridge, the flip cover seat Q4 is arranged at the rear end of the top cover Q5 of the ink cartridge, and is an integrated structure. The identification groove Q2 is installed on the front side of the main body Q1 of the ink cartridge by embedding. The front end of the top cover Q5 is connected by buckling, and the ink cartridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com