Combined aeration treatment device for chemical sewage

A technology for chemical sewage and treatment devices, applied in water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problems of large air bubbles, poor sewage treatment effect, and insufficient gas-liquid mixing, etc. Achieve uniform mixing, provide aeration efficiency and aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

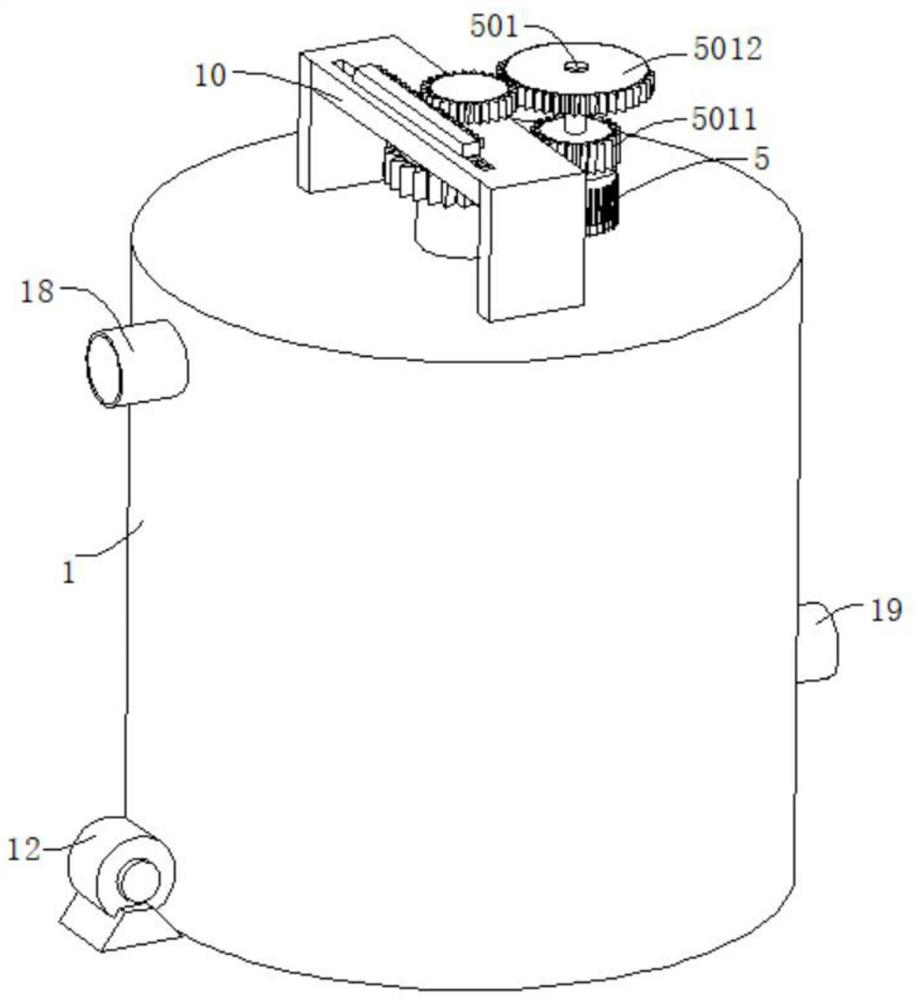

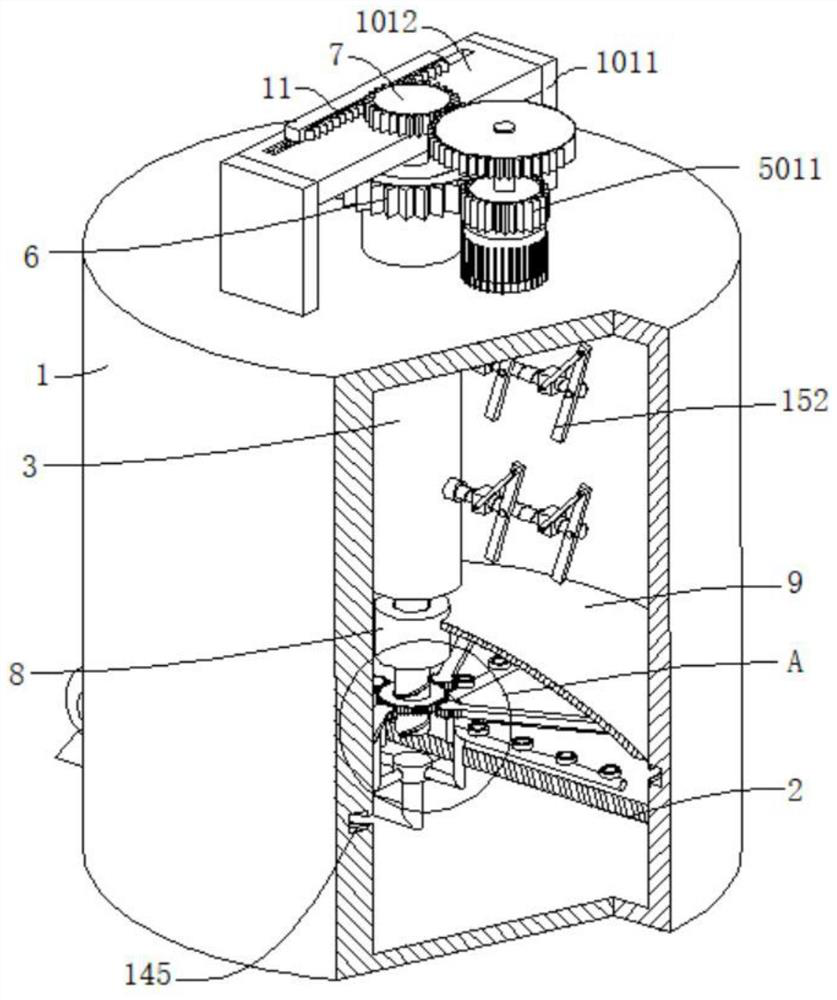

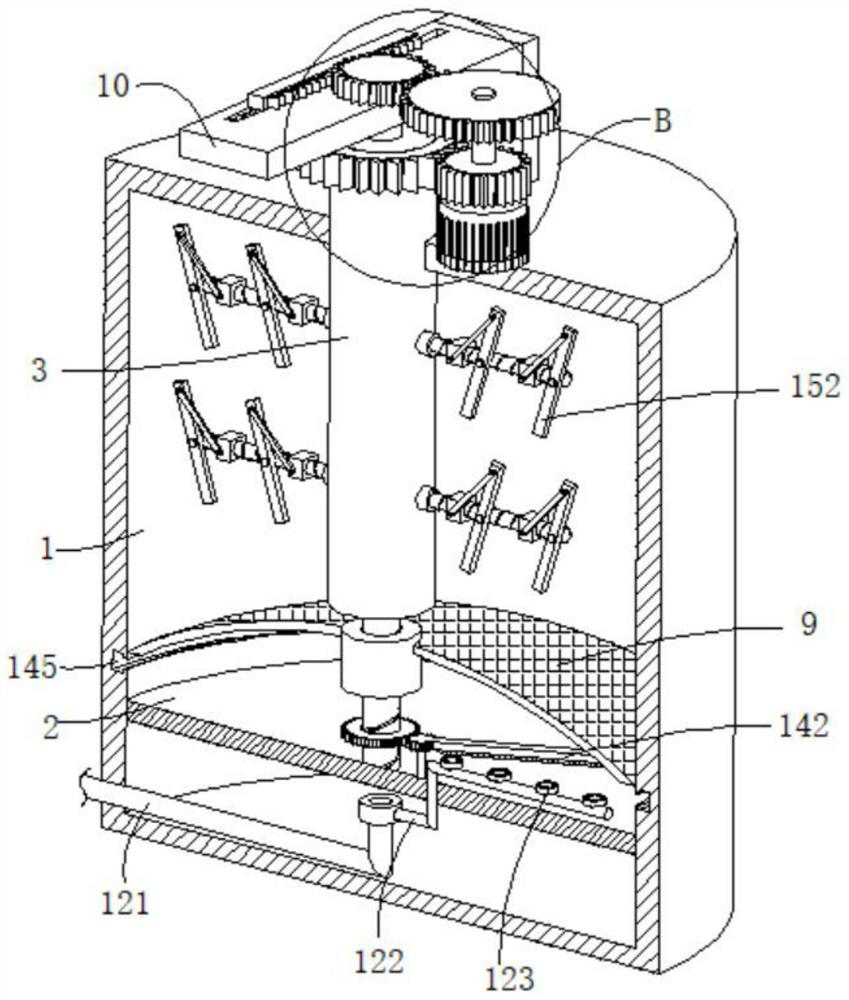

[0036] refer to figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 and Figure 8 , a combined aeration treatment device for chemical sewage, comprising a tank body 1, an aeration mechanism is arranged in the tank body 1, a bottom plate 2 is connected to the inner wall of the tank body 1, and a casing 3 is connected to the top inner wall of the tank body 1 in rotation, The outer wall of the casing 3 is connected with a stirring mechanism, and the inside of the casing 3 is connected with a threaded rod 4 through the first bearing. The output end is connected with a rotating shaft 501, the outer wall of the rotating shaft 501 is connected with a first gear 5011 and a second gear 5012, and the second gear 5012 is a half gear, and the outer wall of the casing 3 is connected with a third gear that meshes with the first gear 5011 6. The outer wall of the threaded rod 4 is connected with the fourth gear 7 which meshes with the second gear 5012, the outer wall of the tank bod...

Embodiment 2

[0042] refer to Figure 2-4 , a combined aeration treatment device for chemical sewage, which is basically the same as in Example 1, furthermore, the aeration mechanism includes a blower 12, the blower 12 is connected to the outer wall of the tank body 1, and the air outlet end of the blower 12 is connected with The exhaust pipe 121, the end of the exhaust pipe 121 away from the blower 12 passes through the tank body 1 and is connected with four air distribution pipes 122, the four air distribution pipes 122 are evenly distributed on the outside of the threaded rod 4 in a circle, and the outer wall of each air distribution pipe 122 Both are connected with an aeration head 123.

[0043] Control the operation of the blower 12, so that the air enters the four air distribution pipes 122 through the exhaust pipe 121, and then enters the aeration head 123, so that the air is converted into air bubbles in the aeration head 123 and enters the sewage, so that the oxygen dissolves into ...

Embodiment 3

[0045] refer to figure 2 , image 3 , Figure 4 and Figure 8 , a combined aeration treatment device for chemical sewage, which is basically the same as that of Embodiment 1, furthermore, the outer wall of the threaded rod 4 is connected with a fifth gear 13, and the outer wall of the fifth gear 13 is meshed with a sixth gear 141, The outer wall of the sixth gear 141 is connected with a fixed rod 14, and the fixed rod 14 is connected to the outer wall of the base plate 2 in rotation. The gas head 123 activities offset.

[0046] The end of the connecting plate 142 away from the sixth gear 141 is connected with a moving block 144 , and the inner wall of the tank body 1 is dug with an annular groove 145 matching with the moving block 144 .

[0047] During the rotation of the threaded rod 4, the fifth gear 13 and the sixth gear 141 will mesh with each other, so that the sixth gear 141 drives the connecting plate 142 to rotate with the fixed rod 14 as the center of circle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com