Nickel-based alloy of nuclear power steam generator

A technology of steam generator and nickel-based alloy, applied in metallurgy field, can solve the problems of high price and high cost of steam generator, achieve the effects of improving alloy performance, enhancing high temperature oxidation resistance and corrosion resistance, and reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

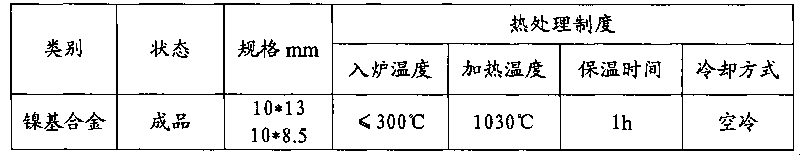

Image

Examples

Embodiment 1

[0008] A nickel-based alloy for steam generators used in nuclear power, its main components and weight percentages are: Ni: 64.8%, Cr: 19.5%, Si: 0.80%, C: 0.080%, Mn: 1.20%, RE: 0.22 %, Cu: 0.50%, Ti: 0.800%, Co: 0.10%, B: 0%, Fe: 12.0%.

[0009] Its production process is:

[0010] 1. Intermediate frequency melting:

[0011] 1.1 Preparation of raw materials: including charge, slag and deoxidizer, the charge is Ni, Cr, Fe and Mn materials, the slag is calcium agent (such as lime, fluorite), and the deoxidizer is aluminum agent (such as Aluminum lime powder), standby after baking;

[0012] 1.2 Charging: Load Ni, Cr and Fe furnace materials that have been baked in step 1.1 into the intermediate frequency melting furnace, and adjust the fluidity of the slag in time to make it good after the furnace materials are melted;

[0013] 1.3 Refining: low-power chemical material, after the material is melted by 70%, add 3% of the total amount of slag, (slag system ratio: lime: fluorite...

Embodiment 2

[0071] The same as the nickel-based alloy for nuclear power steam generators in Example 1, the difference is that the weight percentages of each component are Ni: 72.0%, Cr: 16.8%, Si: 0.50%, C: 0.10%, Mn: 0% , RE: 0.08%, Cu: 0%, Ti: 0.519%, Co: 0%, B: 0.001%, Fe: 10.0%.

Embodiment 3

[0073] A nickel-based alloy for nuclear power steam generators as in Example 1, the difference is that the weight percentages of each component are: Ni: 77.5%, Cr: 14.0%, Si: 0.20%, C: 0.495%, Mn : 0.61%, RE: 0.14%, Cu: 0.30%, Ti: 0.150%, Co: 0.05%, B: 0.0005%, Fe: 7.0%.

[0074] performance test table

[0075] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com