High-niobium Q460-grade fire-resistant steel and manufacturing method thereof

A manufacturing method and refractory technology, applied in the direction of temperature control, etc., can solve the problems of restricting the market promotion and application of refractory steel, large amount of precious alloy addition, high manufacturing cost, etc., and achieve high production efficiency, easy welding, and short production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

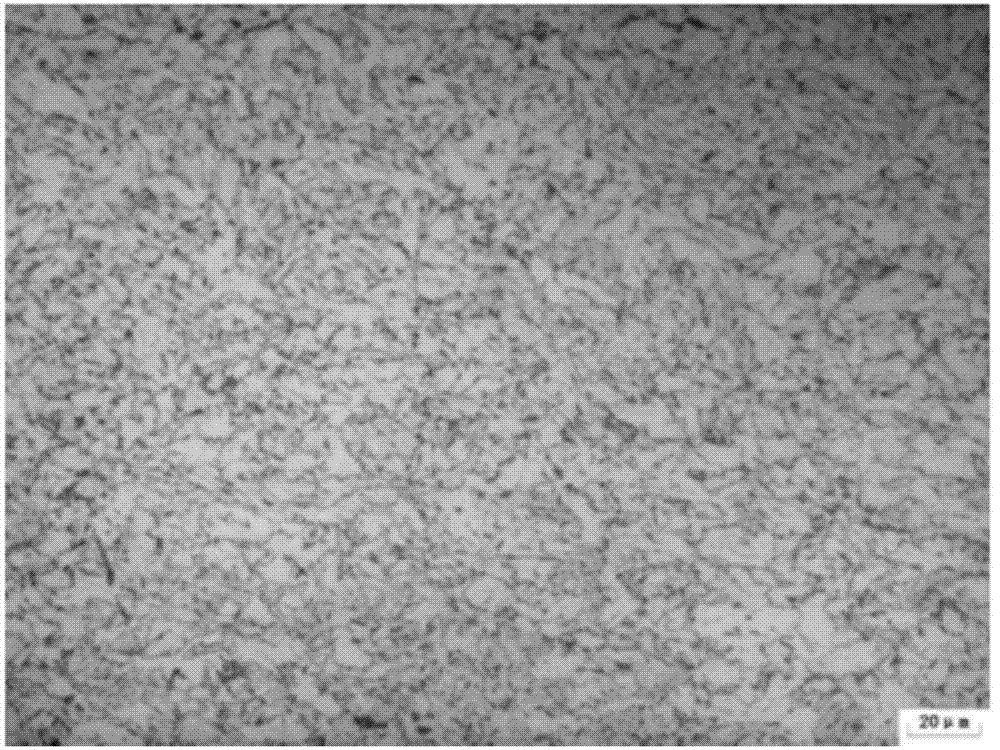

Image

Examples

Embodiment

[0035] A method for manufacturing high-niobium Q460 grade intelligent fire-resistant steel, comprising the following steps:

[0036] 1) Chemical composition by weight percentage: C: 0.01-0.20%, Si: 0.1-0.4%, Mn: 0.5-1.5%, Cr: 0.1-1.0%, Mo: 0.01-0.2%, Nb: 0.05-0.15% , Ti: 0.01~0.05%, P: ≤0.015%, S: ≤0.0020%, the balance is Fe and unavoidable impurities, and the total amount of impurity elements does not exceed 0.05%.

[0037] According to the production process of the present invention, the actual chemical composition of the smelting and rolling steel of the present invention is shown in Table 1.

[0038] Table 1 Chemical composition (wt%) of the embodiment of the present invention;

[0039] ;

[0040] 2) The rolling process is as follows: the heating temperature is 1150 ℃ ~ 1250 ℃, the heating time is 120 ~ 200min; the finishing rolling temperature of rough rolling is 1000 ~ 1050 ℃, the thickness of intermediate billet / finished product is 2 ~ 5; the starting temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com