High-strength long-fatigue life wheel steel used for heavy truck and manufacturing method thereof

A fatigue-life and high-strength technology, applied in the field of high-strength stamped heavy-duty truck wheel steel, can solve the problems of low strength and thick steel plate fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

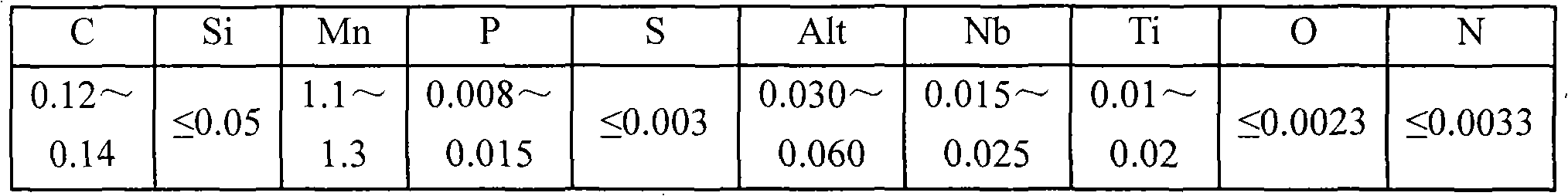

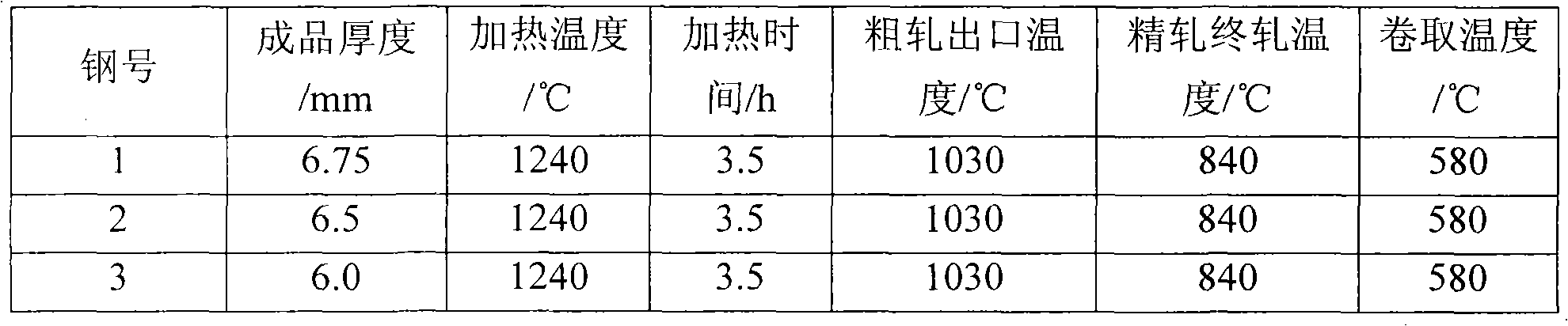

[0019] According to the production process of wheel steel for heavy-duty trucks with high strength and high fatigue life, the wheel steel is trial-manufactured on site.

[0020] The smelting process is as follows: firstly carry out pretreatment and desulfurization of molten iron, then carry out converter smelting, the target temperature at the end point is 1640°C, use Al-Fe alloy for deoxidation, the amount of Al added is 4kg / t, use Mn-Fe alloy with Mn, and use Nb-Fe alloy Nb blending; followed by LF furnace refining treatment, maintaining a reducing atmosphere in the furnace, strong stirring for desulfurization, using Mn-Fe alloy to adjust Mn, using Ti-Fe alloy to adjust Ti, the temperature at the end of refining is controlled at 1560 ° C, and the furnace remains reduced Strong agitation and desulfurization; the last stage is continuous casting, using argon full-protection casting, and the liquid level fluctuation of the crystallizer is within ± 3mm. Strictly control the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com