Pile casing and water-rich strata shield pile casing receiving method

A technology of water-rich layer and casing, applied in wellbore lining, underground chamber, tunnel lining, etc., can solve the problems of low work efficiency, hidden safety hazards of shield tunneling, long construction period, etc., and achieve short installation time and fast filling speed. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

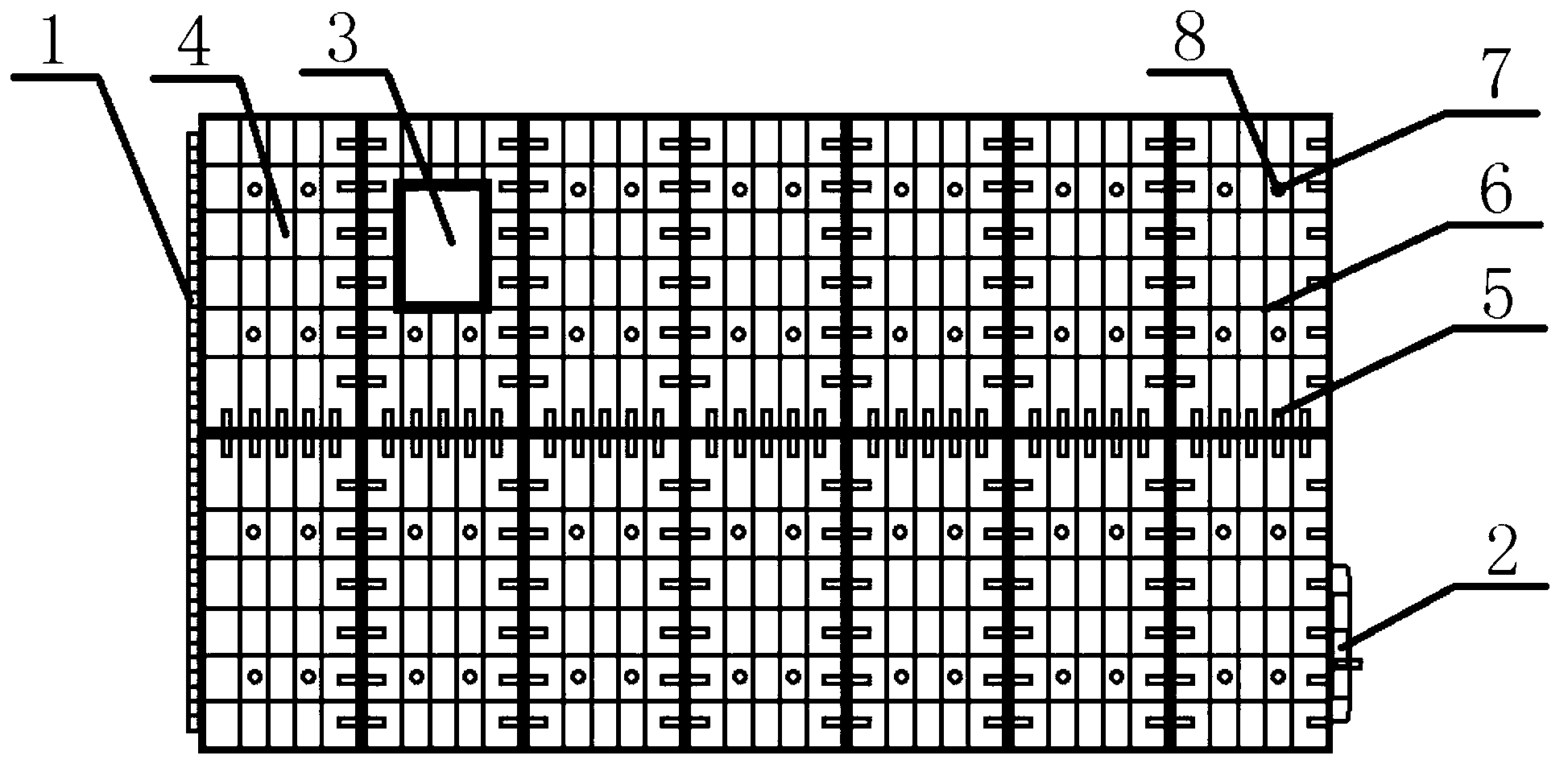

[0016] In the figure, 1-inner flange, 2-access manhole, 3-inspection manhole, 4-tube plate, 5-high-strength bolt, 6-reinforcing rib, 7-valve, 8-grouting hole.

[0017] Such as figure 1 As shown, the inner flange 1 is located on one side of the cylinder, the access manhole 2 is located on the other side of the cylinder, and the inspection manhole 3 is located on the cylinder. The cylinder is composed of multiple cylinder plates 4, and the cylinder plate 4 is 16mm thick Made of steel plates, the 4 tube plates are connected by high-strength bolts 5 , multiple horizontal and vertical reinforcing ribs 6 are installed on the tube plate 4 , and four grouting holes 8 are opened, and valves 7 are installed on the grouting holes 8 .

[0018] Reinforce the soil of the well at the receiving end of the shield, build a concrete base on the soil and pre-embed the steel ring of the door f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com