Method for preparing fibroin nanofiber yarn with high degree of orientation by waste silks

A nanofiber, highly oriented technology, applied in spinning solution preparation, fiber processing, fiber chemical characteristics, etc., can solve the problems of difficult to control the size of oriented yarn, reduce production efficiency, limit promotion and application, etc., and achieve excellent biological Compatibility and biodegradability, good mechanical properties, improved low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

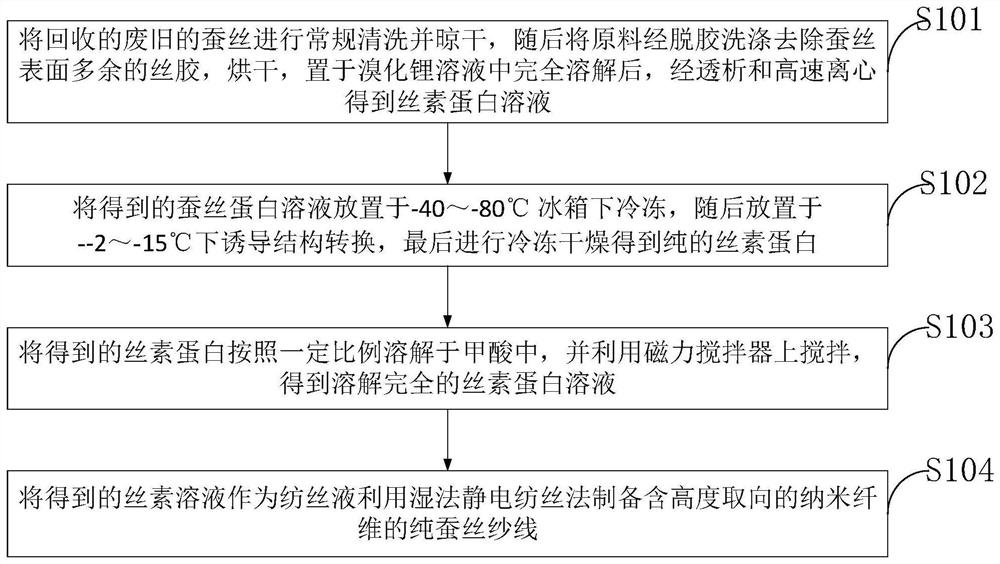

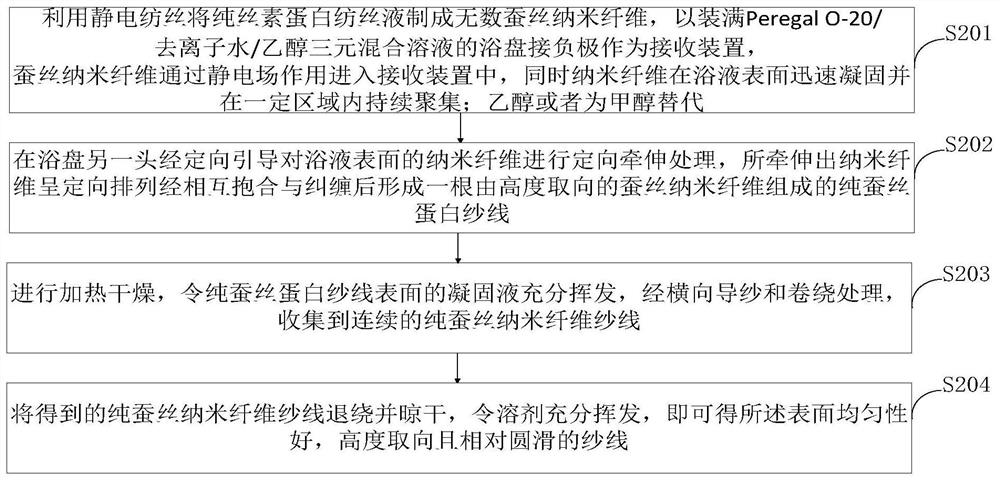

[0065] The waste silk raw materials are degummed and washed to remove excess sericin on the surface of the silk, dried, placed in lithium bromide solution to dissolve completely, and then obtained by dialysis and high-speed centrifugation to obtain a silk protein solution, and then the solution is placed in a refrigerator at -40°C to freeze. After completion, freeze-dry to obtain pure silk fibroin, and then dissolve it in formic acid in a certain proportion. Since silk fibroin dissolves faster in formic acid, it can be dissolved by stirring on a magnetic stirrer for half an hour under normal circumstances. The complete silk fibroin solution, and then the spinning solution with a certain concentration will be used for wet electrospinning. In the process of wet electrospinning, the positive electrode is connected to the needle of the syringe, and the negative electrode is connected to the bath plate collector (the bottom of the bath plate is a circular copper plate), and the bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com