Catalyst for synthesizing diphenyl carbonate in phenol oxidative carbonylation as well as preparation method and application method of catalyst

A technology of diphenyl carbonate and an application method is applied in the field of rod-shaped nano-CeO2-supported Pd catalyst and its preparation, which can solve the problems of difficult post-processing, slow reaction rate, large amount of auxiliary agents, etc., and achieves difficult recycling and low cost. , the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

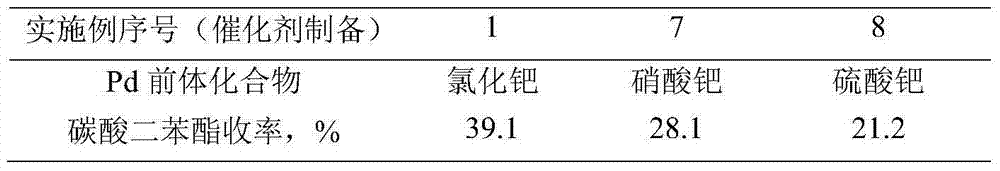

Embodiment 1

[0030] (1) Weigh out 0.064g PdCl 2 (Containing Pd0.038g), and dissolve it in 5mL 25% ammonia water;

[0031] (2) Weigh 6.0g Ce(NO 3 ) 3 ·6H 2 O, (theoretically get CeO 2 2.379g) Mix it with 84.2g NaOH (2.104mol) in solid form, add 150mL deionized water, stir to obtain a suspension;

[0032] (3) The solution obtained in step (1) is added to the suspension obtained in step (2), and then transferred to a crystallization kettle lined with polytetrafluoroethylene. Put the crystallization kettle into the oven and react at 110°C for 24 hours;

[0033] (4) After the reaction, the reaction mixture was taken out of the crystallization kettle, centrifuged, and the obtained solid was washed with deionized water, and then dried at 80°C for 20 hours;

[0034] (5) The solid material obtained after drying is calcined at 500°C for 4 hours to obtain rod-shaped nano CeO 2 Support Pd catalyst.

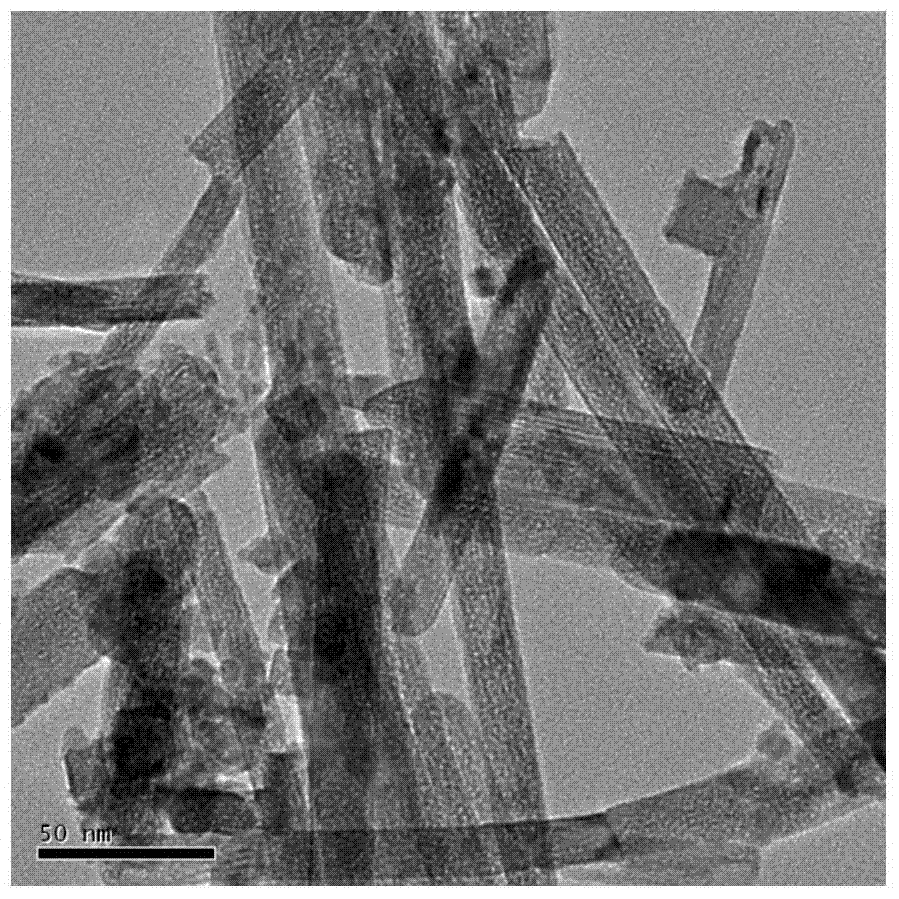

[0035] The prepared catalyst was characterized by transmission electron microscope, the results are as follows ...

Embodiment 2

[0037] The rod-shaped nano CeO prepared in Example 1 2 The supported Pd catalyst is used for the oxidative carbonylation of phenol to prepare diphenyl carbonate.

[0038] 2.4g phenol (0.0255mol), 0.5g catalyst (calculated as Pd is 6.94×10 -5 mol) and 0.55g of tetrabutylammonium bromide (0.0017mol) were added to the tank reactor, and then 4g of dehydrating agent 4A molecular sieve and 20mL of solvent dichloromethane were added to the reactor; filled with 0.6MPa oxygen and 6MPa carbon monoxide, React at 100°C for 4 hours. The reaction liquid was filtered under reduced pressure to separate the catalyst and the reaction liquid, and the reaction liquid was analyzed by liquid chromatography. The yield of diphenyl carbonate was 39.1%.

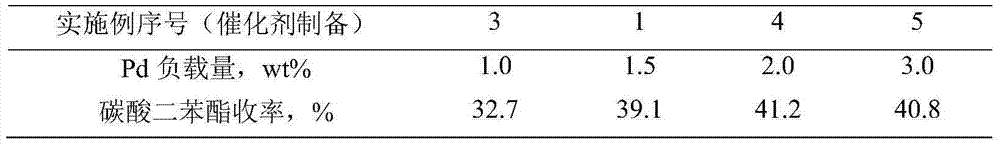

Embodiment 3~5

[0040] The preparation method is the same as in Example 1, except that the Ce(NO 3 ) 3 ·6H 2 The amount of O was 9.0g, 4.5g and 3.0g respectively, and the prepared Pd loading amount (Pd / CeO 2 Mass ratio) of rod-shaped nano CeO 2 Support Pd catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com