Control method for graded preheating of powder bed and additive manufacturing device

A technology of grading preheating and control method, which is applied in the field of additive manufacturing, can solve the problems of affecting the quality of the lower layer powder laying parts, not considering the melting section information, and the difficulty of uniform temperature field, etc., and achieves the difficulty of powder cleaning and post-processing. The effect of reducing and improving powder utilization and improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment includes the following steps:

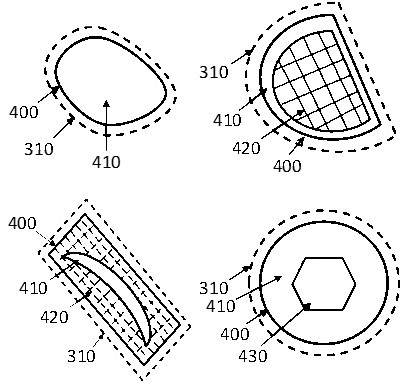

[0085] Step 1: The forming substrate 100 selects a 316L stainless steel substrate with a size of 150×150mm, imports a 3D model, the model size is 80×80×30mm, the slice thickness is 0.05mm, the scanning path is set, the surface layer is indented to 0.04mm, layer by layer The rotation angle is 90°, and the section information of each layer is obtained, and its section data is imported into the electron beam selective melting forming equipment, and the powder is added to the powder bin of the equipment at the same time, the powder is Ti 2 AlNb alloy powder, set the relevant processing parameters.

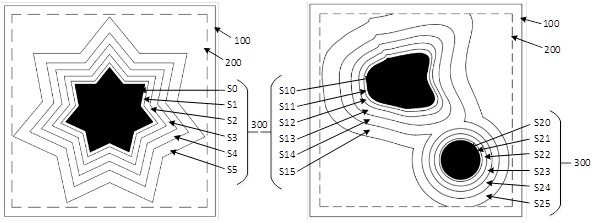

[0086] Step 2: Set the preheating area 200 to 140×140mm, identify the cross-sectional information of each layer through the computer program, and determine the preheating range S0 of the 0th grade in each layer according to the imported calculation formula and method, and the grading range S0 of the third layer in the third layer. ...

Embodiment 2

[0095] This embodiment includes the following steps:

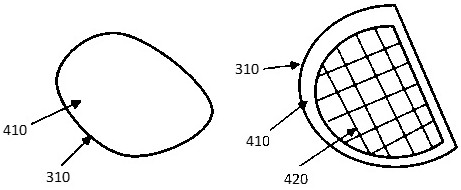

[0096] Step 1: The forming base 100 selects a molybdenum substrate with a size of Φ160mm and imports the 3D model. The cross-sectional information of one layer of the model is as follows: Figure 5 As shown, the slice thickness is 0.07mm, the scanning path is set, the indentation of the surface layer is 0.02mm, and the layer-by-layer rotation angle is 90°, the section information of each layer is obtained, and the section data is imported into the electron beam selective melting forming equipment, and at the same time Add the powder into the powder bin of the equipment, the powder is molybdenum alloy powder, and set the relevant processing parameters.

[0097] Step 2: Set the preheating area 200 to Φ150mm. The computer software first identifies all the imported cross-section information. For parts with irregular cross-sections, typical size information can be obtained. The size information is not less than 3. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com