Ketone oxime ester photoinitiator green synthetic method

A photoinitiator and green synthesis technology, applied in the preparation of sulfides, organic chemistry, etc., can solve the problems of increased use of acid chlorides and catalysts, increased costs, waste of raw materials, etc., to reduce post-processing operations, low production costs, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

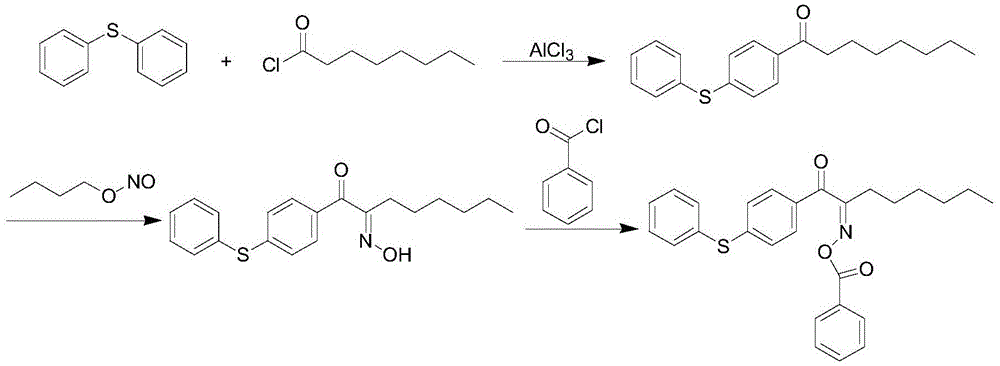

Method used

Image

Examples

Embodiment 1

[0032] a. Preparation of diphenyl sulfide cyclopentyl acetone

[0033] Add 111.8g of diphenyl sulfide (0.6mol), 1mol of zirconium catalyst and 600ml of dichloromethane into a four-necked flask equipped with an electric stirrer and a thermometer, pass through nitrogen protection, and reduce the temperature of the reaction solution to -5~ 0°C, then dropwise added a mixed solution of 126.9g octanoyl chloride (0.78mol) and 150g of dichloromethane, after the dropwise addition was completed, the temperature was raised to 15°C and stirring was continued for 2 hours. After the reaction was completed, the reaction solution was poured into 2000ml of 1mol / L dilute sulfuric acid, and the lower organic phase was separated. The aqueous phase was extracted with 300 ml of dichloromethane. The organic phases were combined, washed once with 500ml of saturated sodium bicarbonate solution, and then washed three times with 500ml of water until neutral, added 200g of anhydrous magnesium sulfate fo...

Embodiment 2

[0039] a. Preparation of diphenyl sulfide cyclopentyl acetone

[0040] Add 111.8 g of diphenyl sulfide (0.6 mol), 2 mol of zirconium catalyst and 500 ml of chloroform into a four-necked flask equipped with an electric stirrer and a thermometer, pass through nitrogen protection, and lower the temperature of the reaction solution to 0-5°C. Then, a mixed solution of 146.4 g of octanoyl chloride (0.9 mol) and 200 g of chloroform was added dropwise, and after the dropwise addition, the temperature was raised to 15° C. and stirring was continued for 2 hours. After the reaction was completed, the reaction solution was poured into 2000ml of 2mol / L dilute hydrochloric acid, and the lower organic phase was separated. The aqueous phase was extracted with 300 ml of chloroform. Combine the organic phases, wash once with 500ml of saturated sodium bicarbonate solution, then wash three times with 500ml of water until neutral, add 200g of anhydrous magnesium sulfate to dry, and distill off ch...

Embodiment 3

[0046] a. Preparation of diphenyl sulfide cyclopentyl acetone

[0047] Add 111.8g of diphenyl sulfide (0.6mol), 3mol of zirconium catalyst and 700ml of dichloroethane into a four-necked flask equipped with an electric stirrer and a thermometer, pass through nitrogen protection, and reduce the temperature of the reaction solution to 0~ 5°C, and then dropwise added a mixed solution of 107.4g octanoyl chloride (0.66mol) and 200g of dichloroethane, and after the dropwise addition was completed, the temperature was raised to 15°C and stirring was continued for 2 hours. After the reaction was completed, the reaction solution was poured into 2000ml of 2mol / L dilute hydrochloric acid, and the lower organic phase was separated. The aqueous phase was extracted with 300 ml dichloroethane. Combine the organic phases, wash once with 500ml of saturated sodium bicarbonate solution, then wash three times with 500ml of water until neutral, add 200g of anhydrous magnesium sulfate to dry, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com