Process for preparing trioctyl phosphate by sodium alkoxide method

A technology for the preparation of trioctyl phosphate, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of increased separation difficulty, environmental pollution, and high production costs. Achieve the effect of improving the utilization rate of raw materials, reducing production costs, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

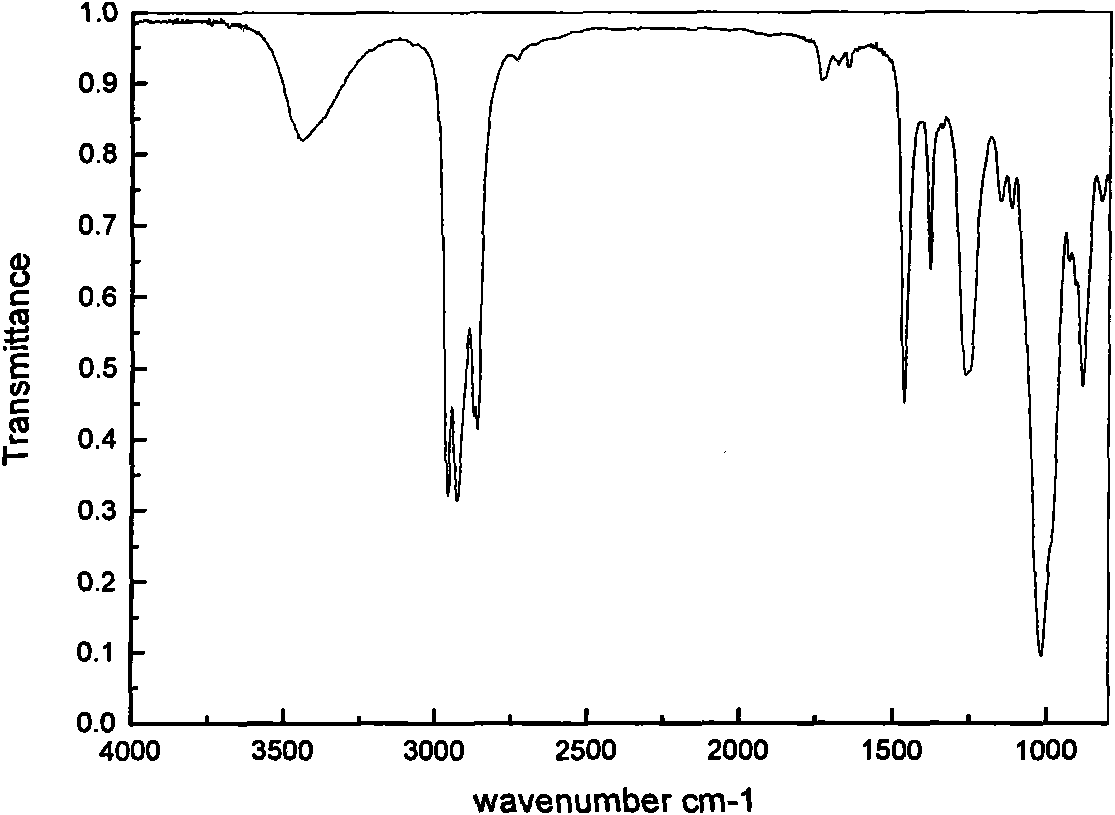

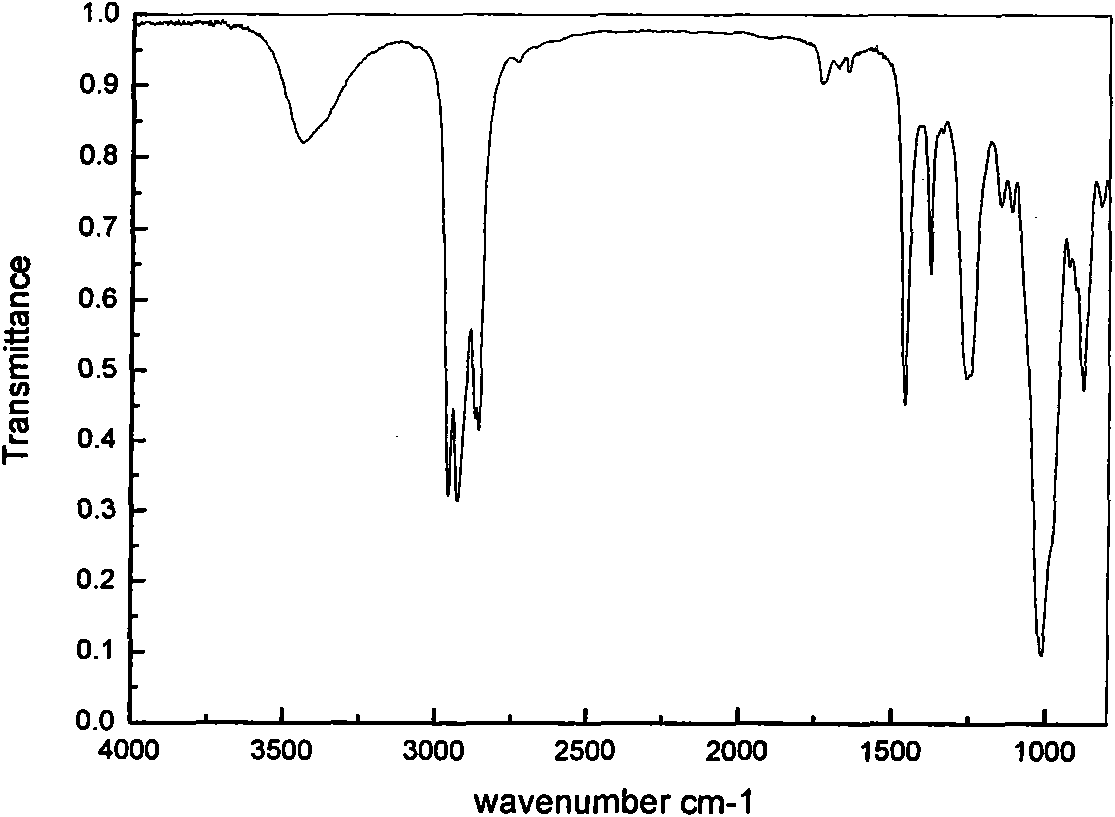

Image

Examples

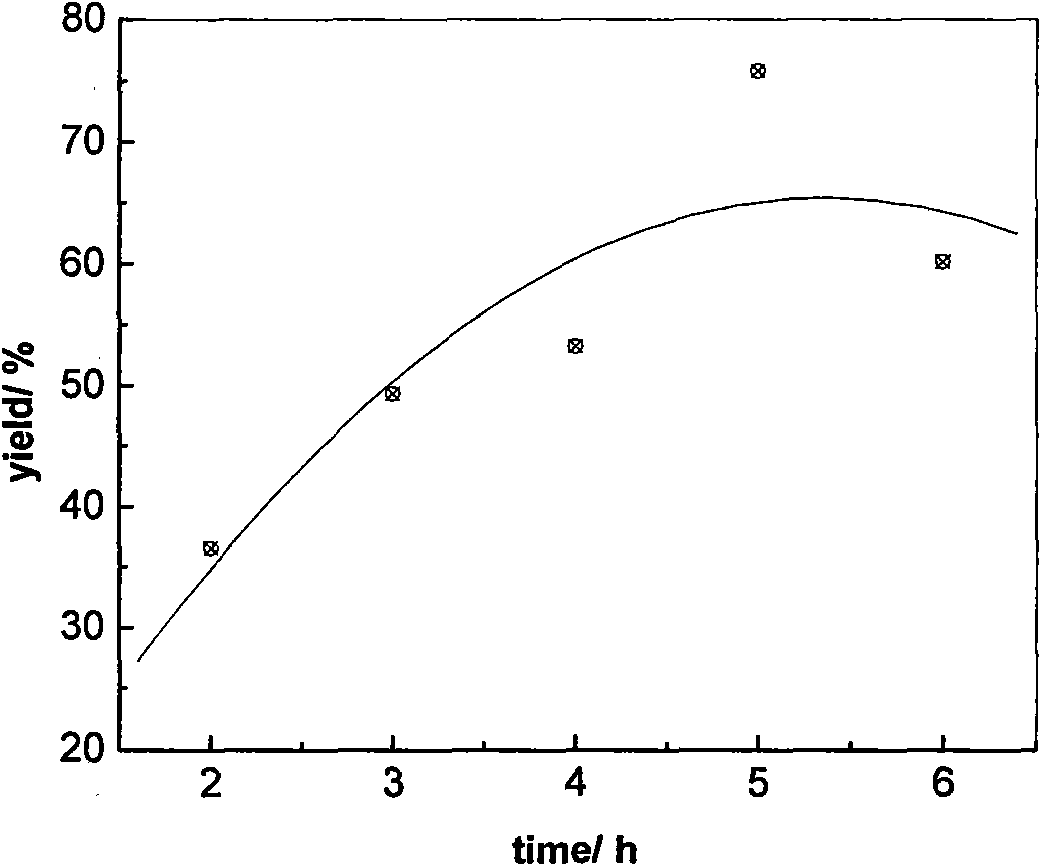

Embodiment 1

[0017] Weigh 250g of octanol and pour it into a four-necked reaction flask (500ml), weigh 11.06g of sodium metal, the molar fraction of sodium alkoxide is 25%, cut the sodium into pieces and put it into the reaction flask. Start the electric stirrer, heat with an electric heating mantle, and control the temperature to about 90°C. Weigh the corresponding stoichiometric amount of phosphorus oxychloride and place it in a constant pressure dropping funnel, and insert the funnel into a four-necked bottle. When the temperature of the reaction solution in the four-necked bottle is lower than 40°C, start to add phosphorus oxychloride dropwise, and control the dropping rate of phosphorus oxychloride (40-50 drops / min). Do not exceed 90°C. After the dropwise addition, the electric heating mantle was turned on to heat the reaction solution. The temperature was raised to 130°C over a period of 40 minutes, and the reaction was carried out at this temperature for 3 hours. Slowly lower the...

Embodiment 2

[0019] Weigh 250g of octanol and pour it into a four-necked reaction flask (500ml), weigh 6.64g of sodium metal, the molar fraction of sodium alkoxide is 15%, cut the sodium into pieces and put it into the reaction flask. Start the electric stirrer, heat with an electric heating mantle, and control the temperature to about 90°C. Weigh the corresponding stoichiometric amount of phosphorus oxychloride and place it in a constant pressure dropping funnel, and insert the funnel into a four-necked bottle. When the temperature of the reaction solution in the four-necked bottle is lower than 40°C, start to add phosphorus oxychloride dropwise, and control the dropping rate of phosphorus oxychloride (40-50 drops / min). Do not exceed 90°C. After the dropwise addition, the electric heating mantle was turned on to heat the reaction solution. The temperature was raised to 140°C over a period of 40 minutes, and the reaction was carried out at this temperature for 4 hours. Slowly lower the ...

Embodiment 3

[0021] Weigh 250g of octanol and pour it into a four-necked reaction flask (500ml), weigh 13.27g of sodium metal, the molar fraction of sodium alkoxide is 30%, cut the sodium into pieces and put it into the reaction flask. Start the electric stirrer, heat with an electric heating mantle, and control the temperature to about 90°C. Weigh the corresponding stoichiometric amount of phosphorus oxychloride and place it in a constant pressure dropping funnel, and insert the funnel into a four-necked bottle. When the temperature of the reaction solution in the four-necked bottle is lower than 40°C, start to add phosphorus oxychloride dropwise, and control the dropping rate of phosphorus oxychloride (40-50 drops / min). Do not exceed 90°C. After the dropwise addition, the electric heating mantle was turned on to heat the reaction solution. The temperature was raised to 130°C over a period of 40 minutes, and the reaction was carried out at this temperature for 5 hours. Slowly lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com