Multi-platform efficient material extrusion additive manufacturing equipment and block printing method

An additive manufacturing, multi-platform technology, applied in the field of additive manufacturing, can solve the problems of rising equipment costs, poor equipment positioning accuracy, and rising material costs, to save materials and costs, increase printing speed, and improve printing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make objects and technical solutions of the present invention more clear and easy to understand. In conjunction with the accompanying drawings and the following embodiments, the present invention will be further described in detail, specific embodiments described herein are merely for explaining the present invention and are not intended to limit the present invention.

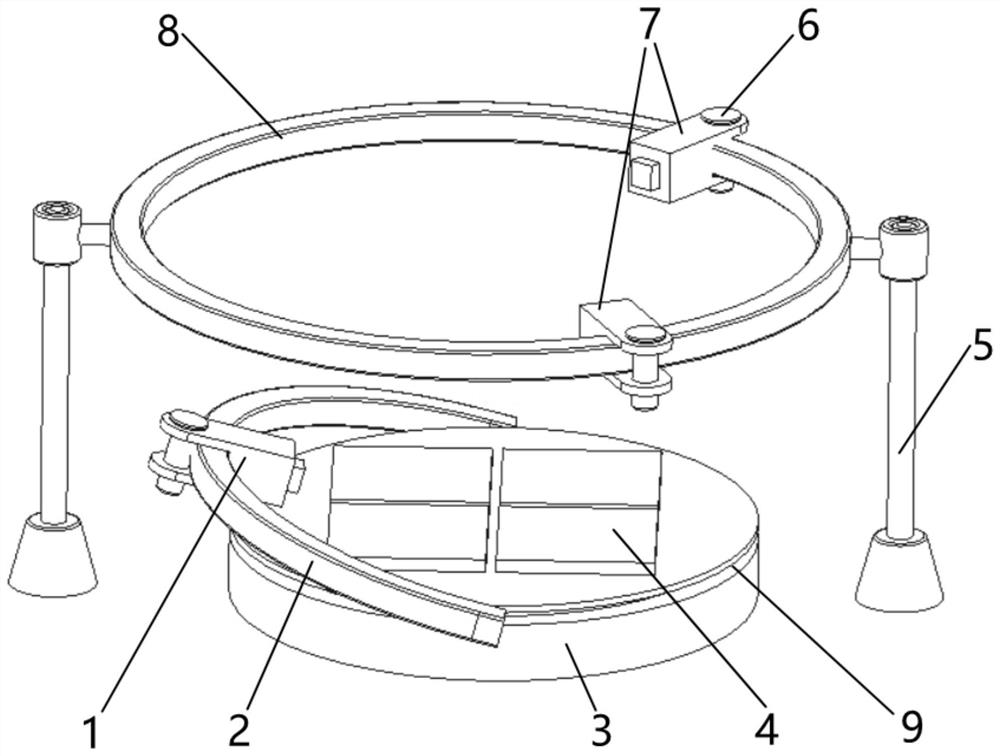

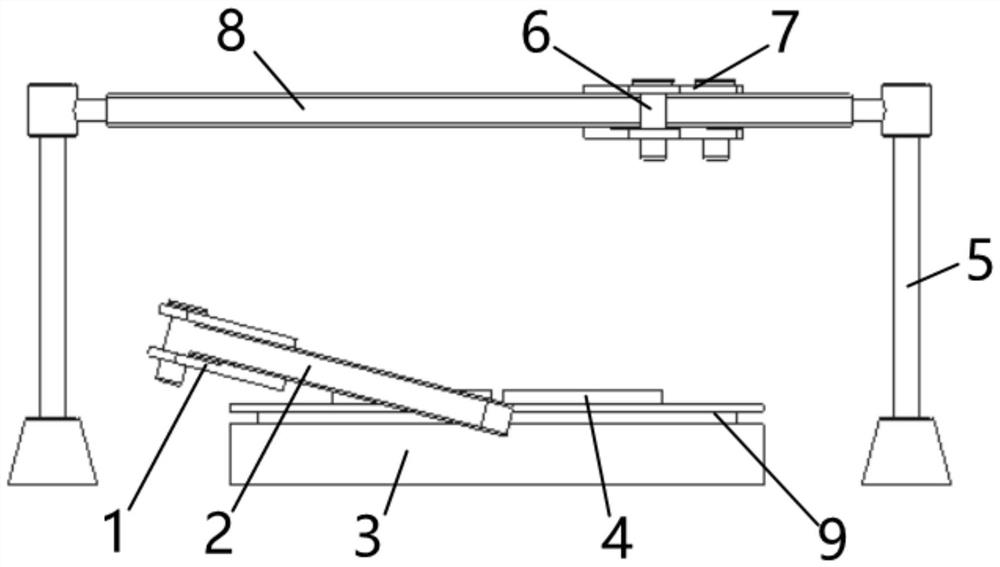

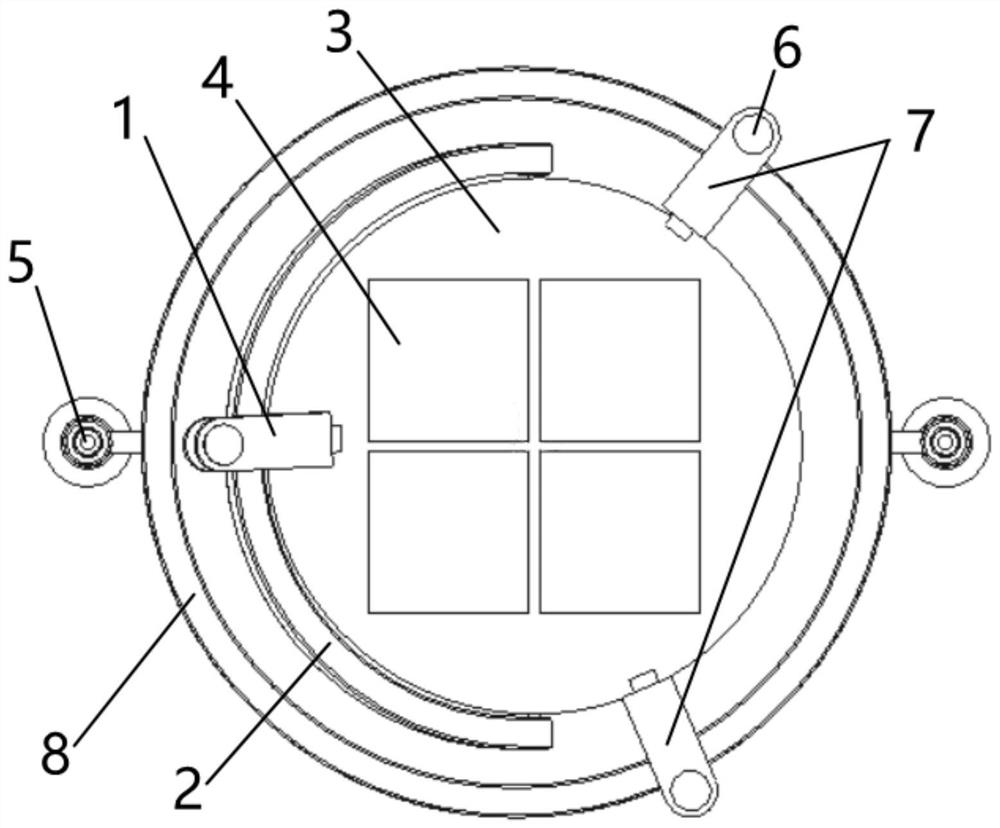

[0042] Refer Figure 1 to 4 An extruded material of high efficiency multi-platform additive manufacturing apparatus includes a base 3, the base is circular cross-sectional shape, and its cross-sectional area is large enough, it can be arranged simultaneously at a plurality of the printing platform. The base 3 is provided with four printing platform 4, four printing platform 4 in the form of two rows and two columns are arranged, the print head comprises a platform 4, not shown in FIG. Four printing platform 4 independently from each other, can be 4, respectively for each of the printing platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com