Printing method of multi-material 3D printer

A 3D printer and multi-material technology, applied in the field of 3D printing, can solve the problems of single printing material, unsatisfactory, and affecting printing speed, and achieve the effects of accurate positioning, good load-bearing performance, and increased printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

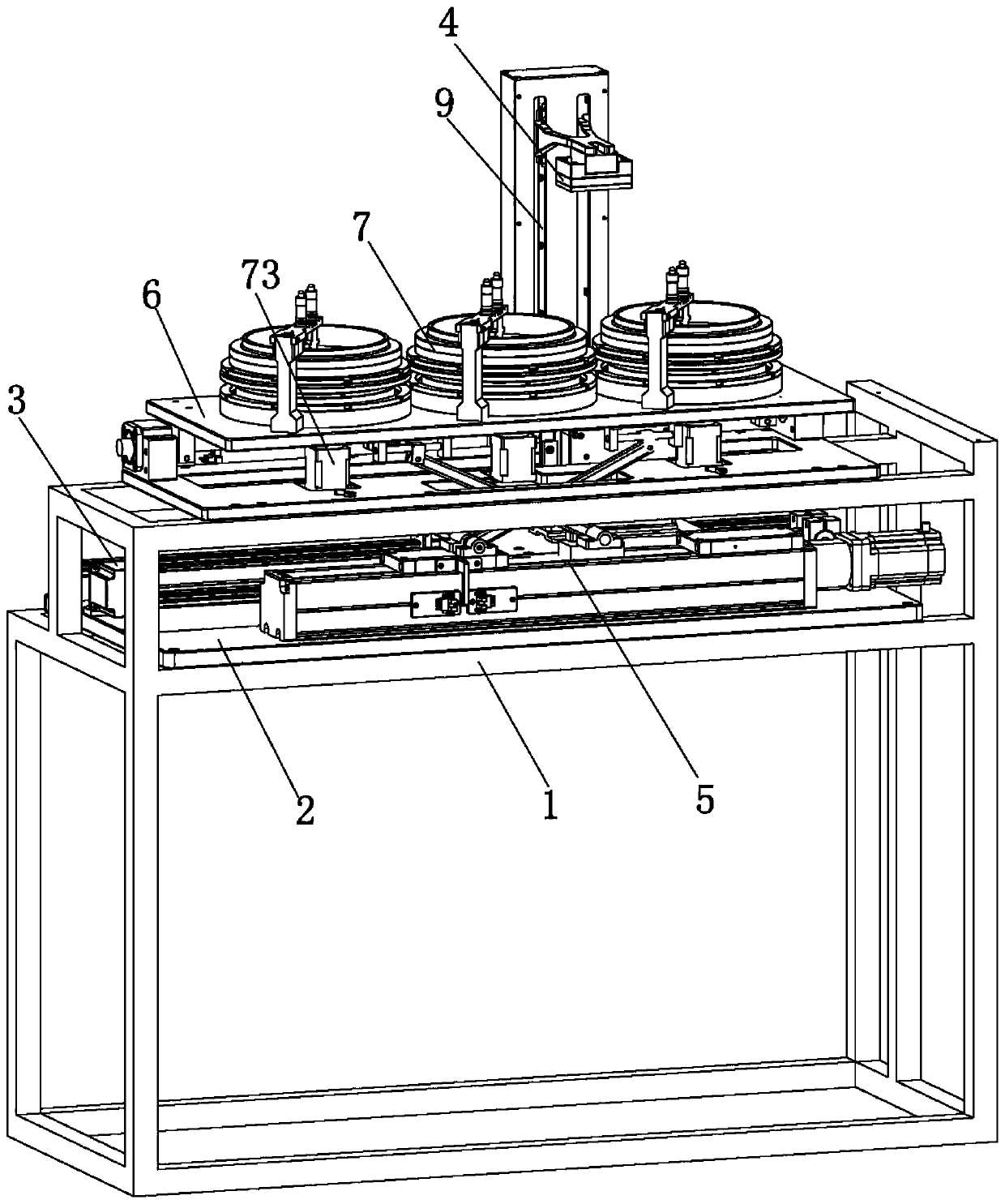

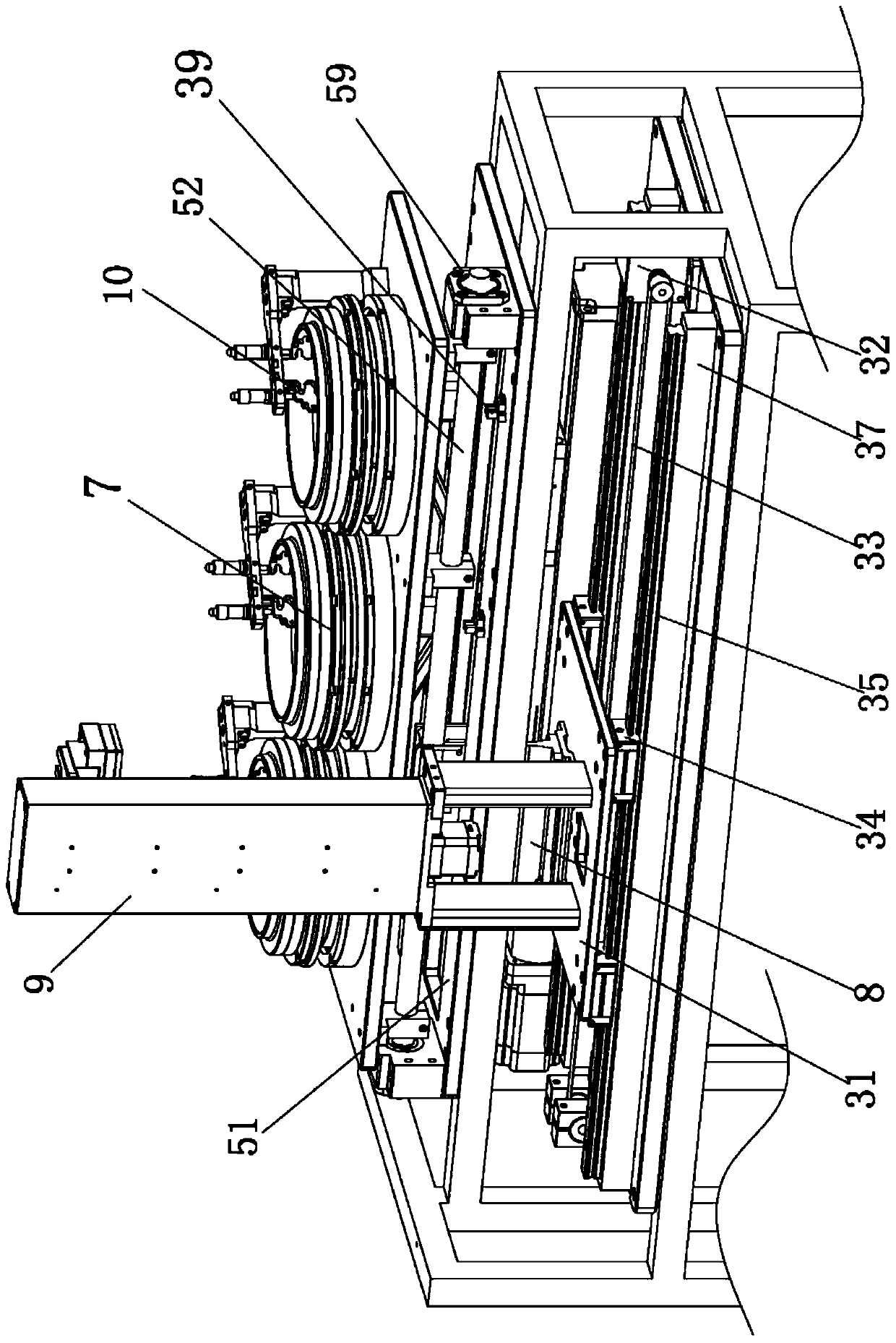

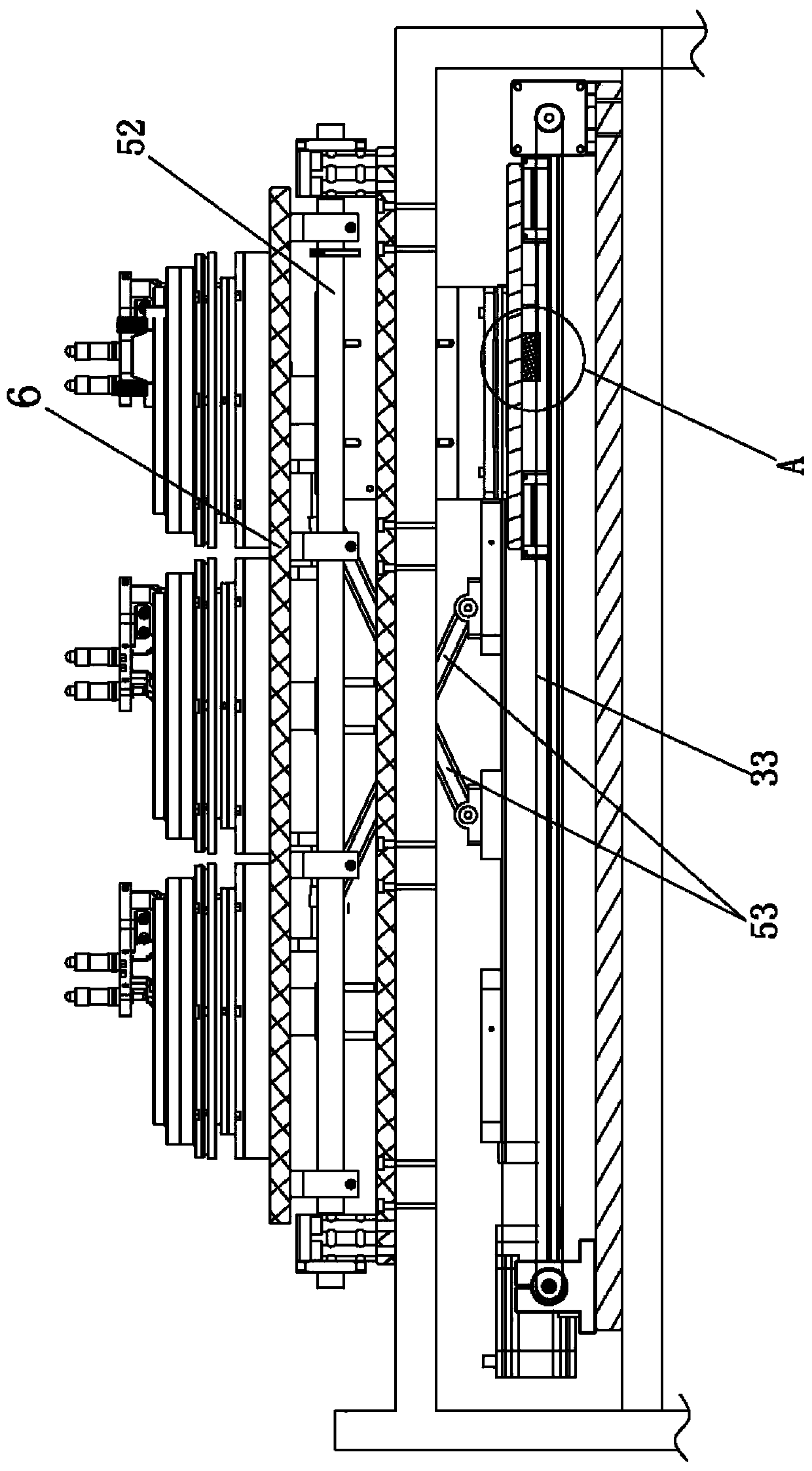

[0043] Please refer to the attached figure 1 to attach Figure 9 As shown, the present invention is a multi-material 3D printer, which can print multiple printing materials onto one printed piece, which consists of a frame 1, a bottom plate 2, a Z-axis translation mechanism 3, a printing platform 4, and an oblique drawing mechanism 5 , mounting plate 6 and at least two material holding mechanisms 7 etc. are assembled from several parts.

[0044] Wherein, the bottom plate 2 is fixedly installed on the frame 1 .

[0045] The Z-axis translation mechanism 3 is supported on the base plate 2 and can move relative to the base plate 2. An optical machine 8 is installed on the Z-axis translation mechanism 3, and the optical machine 8 can move to any position along with the Z-axis translation mechanism 3. The bottom of the material mechanism 7 can cure the printing material, and only one set of optical machine 8 needs to be installed, thereby greatly reducing the cost of the printer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com