Metal surface exposure type powder bed melting additive manufacturing system

An additive manufacturing and powder bed technology, applied in the field of additive manufacturing, can solve the problems of technology promotion bottleneck, high cost and difficulty, and achieve the effect of reducing cost, efficient output and increasing printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

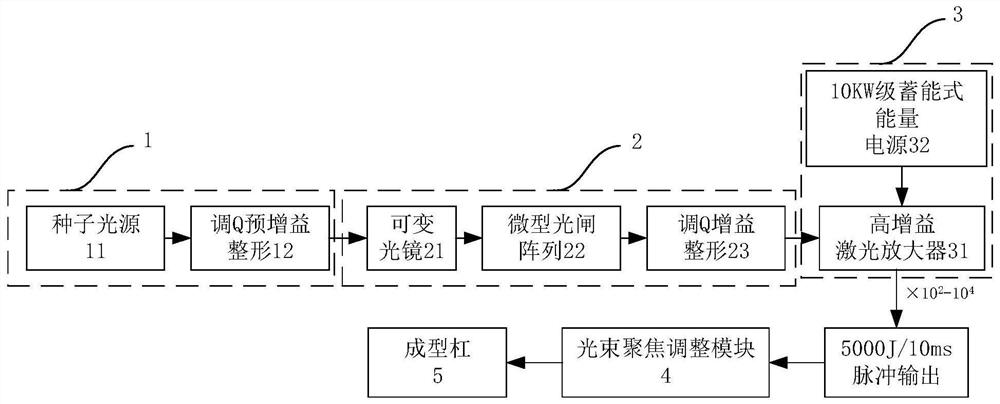

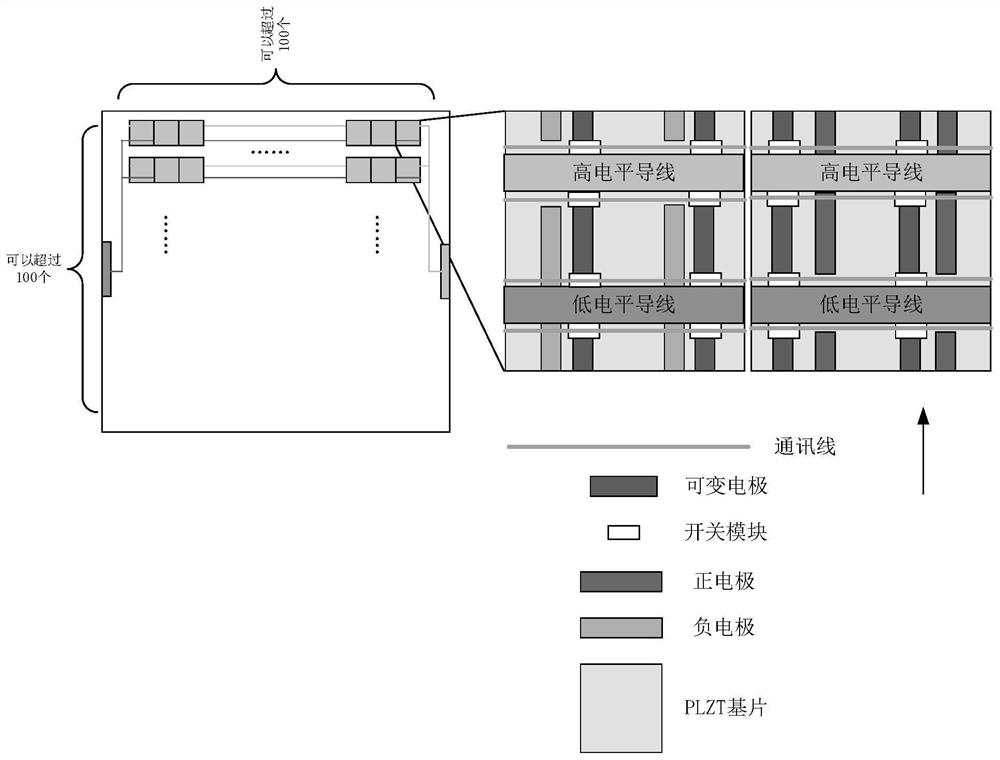

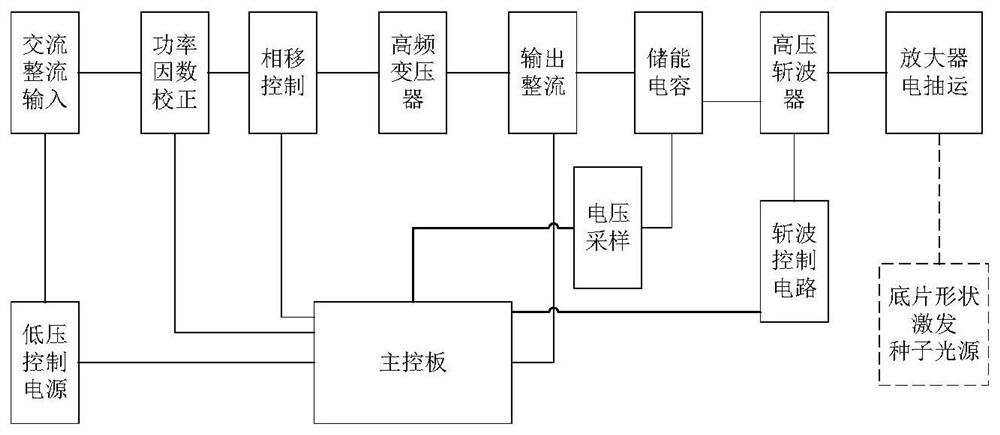

[0034] Such as figure 1 As shown, this embodiment provides a metal surface exposure type powder bed fusion additive manufacturing system, including a laser light source module 1, a negative film module 2, a secondary amplification module 3, a beam focus adjustment module 4 and a forming bar 5 connected in sequence, Wherein, the laser light source module 1 is used to generate laser light; the film module 2 is used to cut the laser light to realize high-precision and low-power film image acquisition; the secondary amplification module 3 is used to collect and obtain the film light Perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com