UV printing technology

A technology of process and printing equipment, applied in the field of UV printing process, can solve the problems of UV printing inks not being able to adhere, multi-layer printing inks interfering with each other, poor printing effect, etc., to reduce the risk of leakage, reduce waste, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

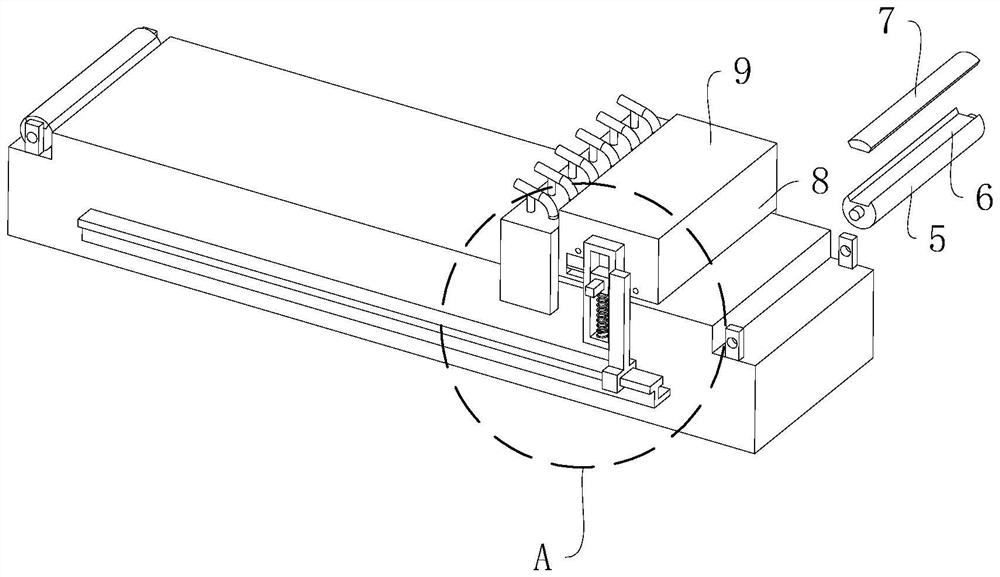

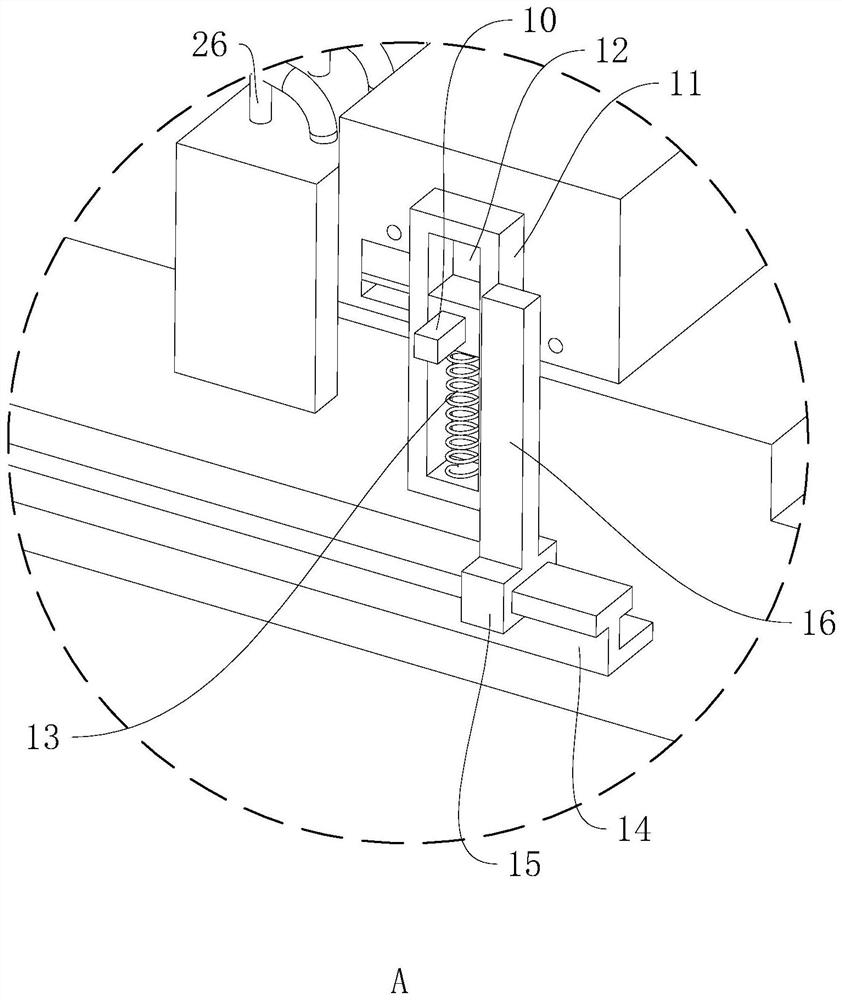

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] see figure 1 , a kind of UV printing process, comprising step 1, finishing preparatory work on printing equipment; Step 2, printing; Step 3, blanking.

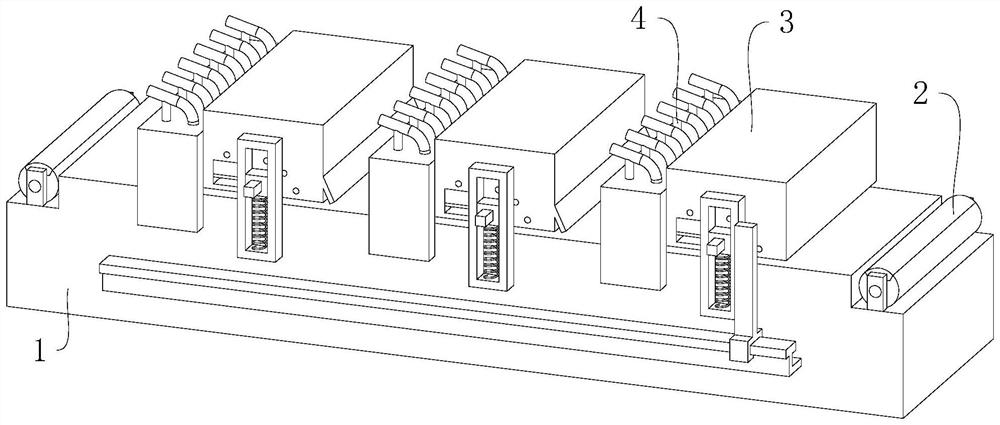

[0039] The printing equipment includes a frame 1 supported on the ground, and a winding assembly 2 , a printing assembly 3 and a drying and fixing assembly 4 located on the frame 1 .

[0040] see figure 1 and figure 2 The winding assembly 2 has two groups and is located at both ends of the frame 1 respectively. The winding assembly 2 includes a winding roller 5 connected to the two ends of the frame 1 through a rotating shaft. The rotation axis of the winding roller 5 is horizontal, and The two winding rollers 5 are parallel, and the side ends of the winding rollers 5 are provided with wedge-shaped slots 6 with both ends passing through along their length direction, and the winding rollers 5 are inserted with wedge-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com