Dot-matrix 3D printing light source utilizing light-emitting diodes

A light-emitting diode and 3D printing technology, applied in the field of 3D printing, can solve the problems of low electro-optic conversion efficiency, low overall work efficiency, expensive devices, etc., and achieve high electro-optic conversion efficiency, low cost, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0015] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

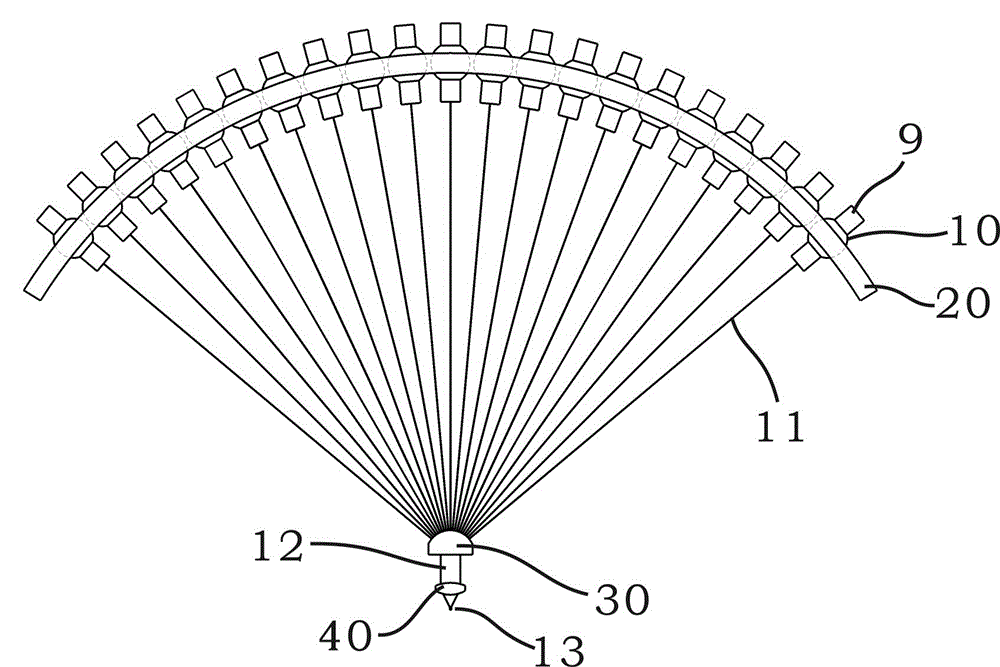

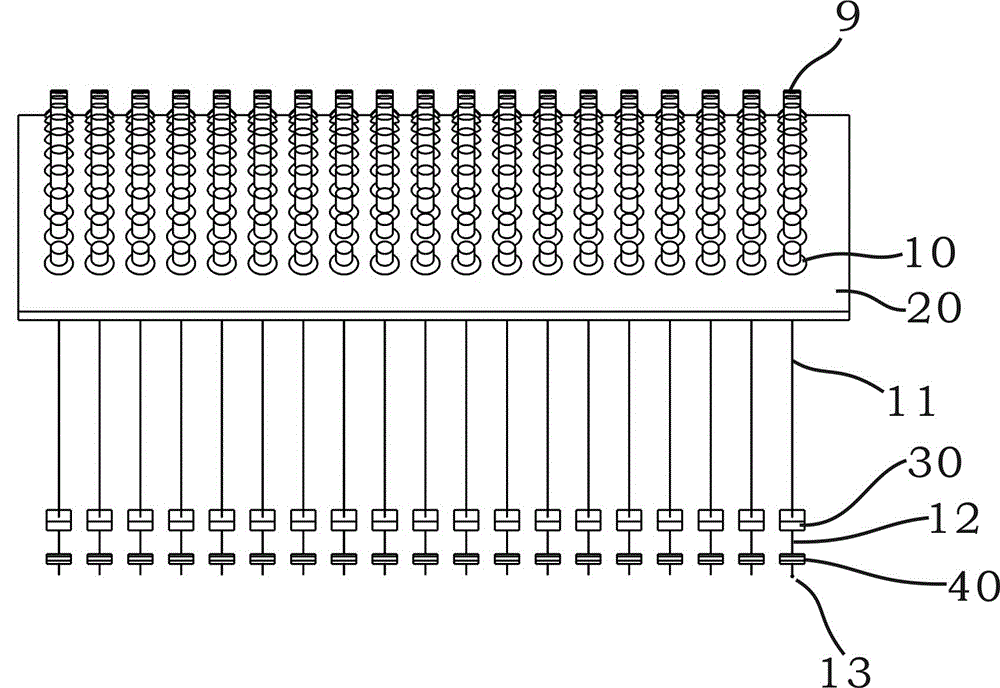

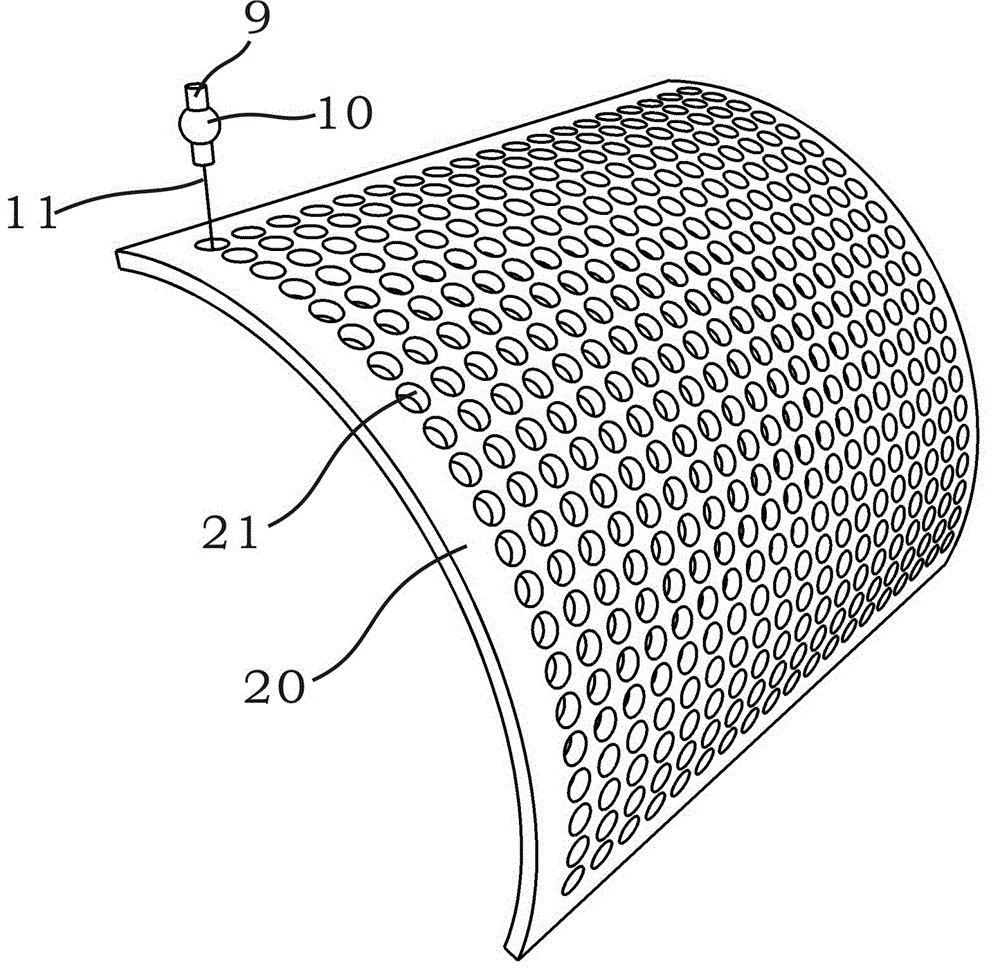

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a dot-matrix 3D printing light source utilizing light-emitting diodes, including: light-emitting diodes 9, a mounting bracket 20, a first condenser lens 30, and a second condenser lens 40; 10. It can emit primary light 11 with a small diffusion angle; the mounting bracket 20 is a cylindrical structure, and at least one or more inner arc surfaces 21 are arranged along the axial and radial directions of the cylinder; the light-emitting diode 9 is adjusted to the outer arc The surface 10 is installed in the inner arc surface 21 of the mounting bracket 20, and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com