Random image processing method and printing device control system

A processing method and technology of printing equipment, applied in printing, printing device and other directions, can solve the problem of not being able to print random images in real time, and achieve the effects of reducing storage space waste, reducing redundant steps, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

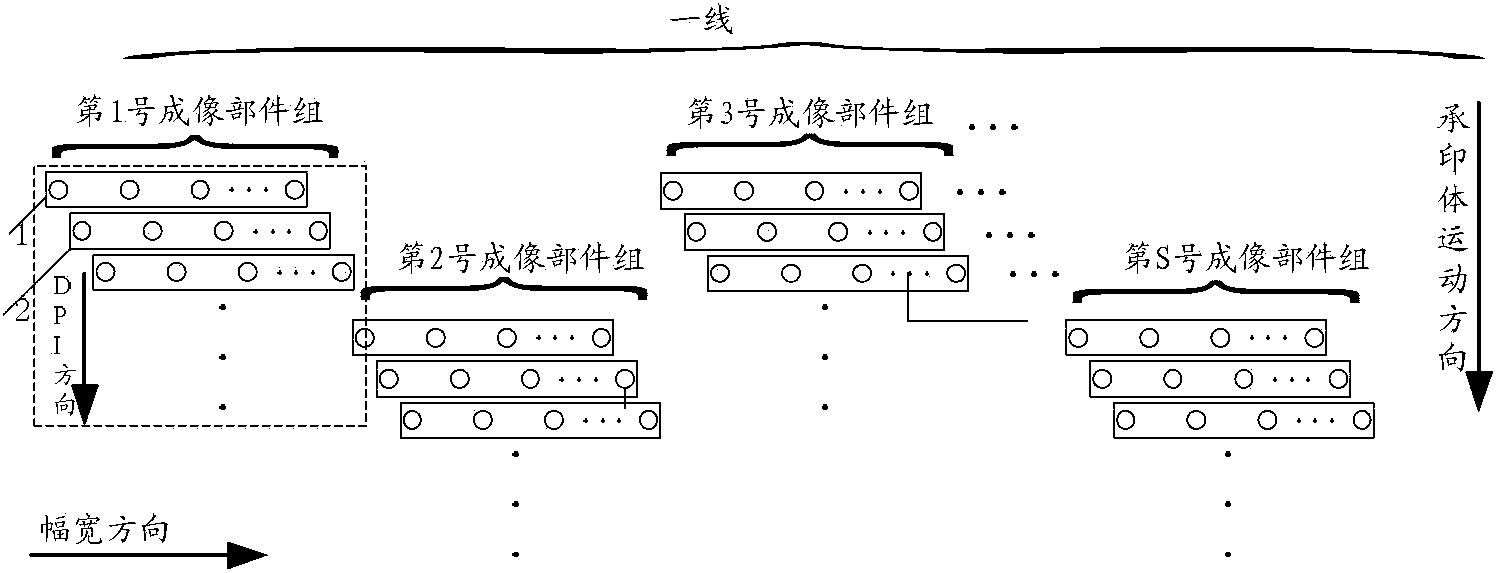

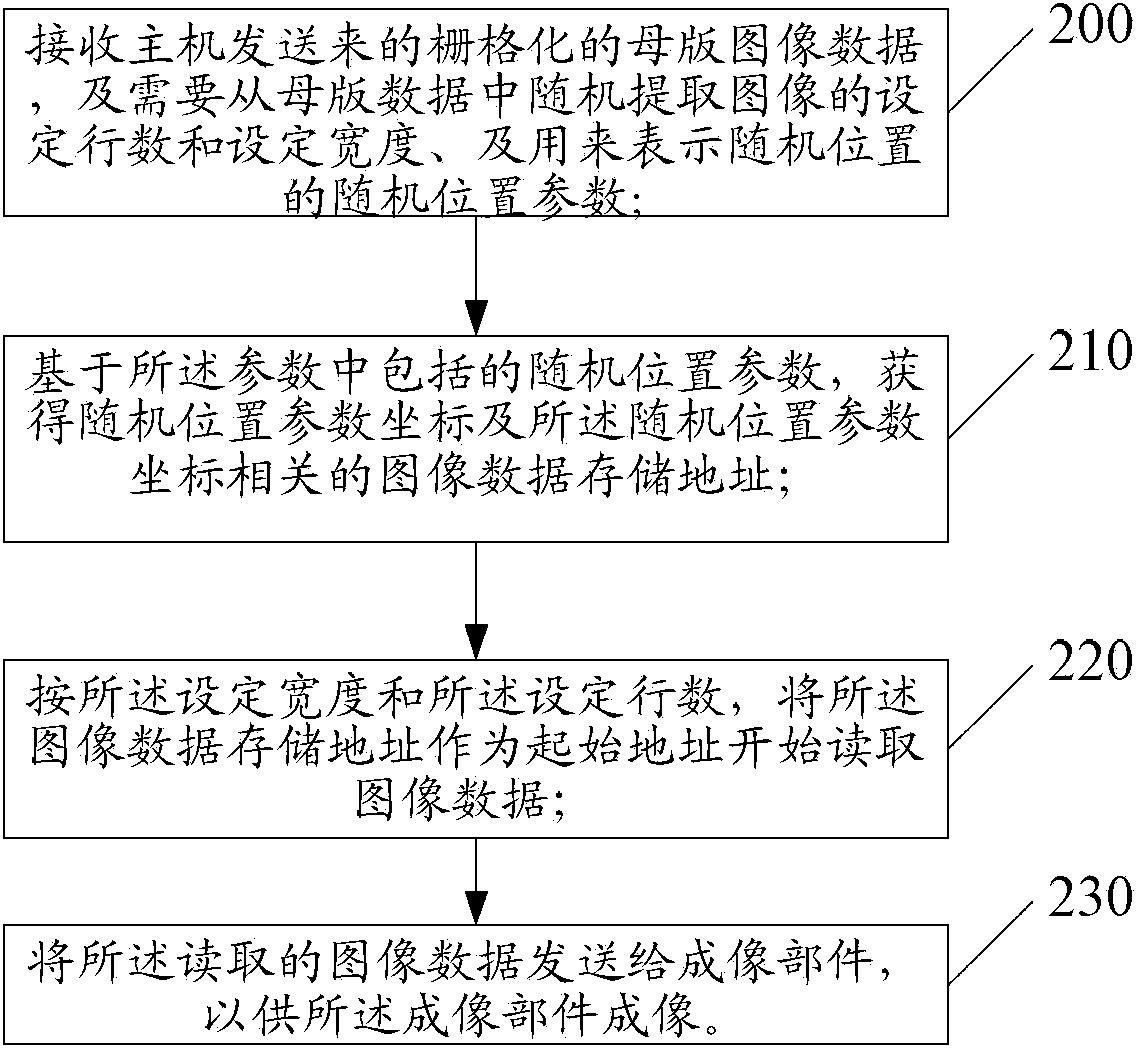

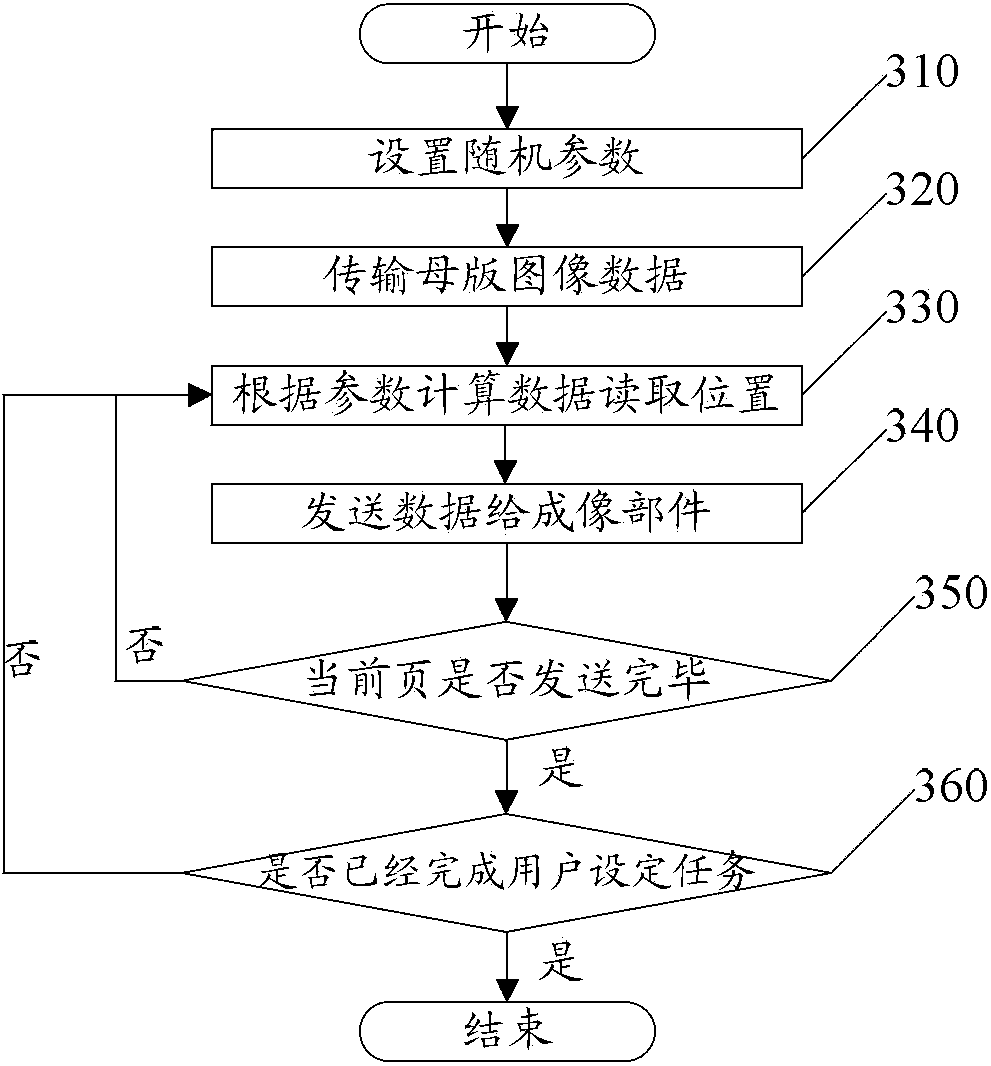

[0062] In this application, the main control computer (referred to as the host) transmits the rasterized master image data to the printing equipment control system, for example: high-speed inkjet printing equipment control system. The host computer passes the size (width*length), number of pages, and generation method of the random position parameters of the image to be randomly extracted to the high-speed inkjet printing equipment control system as parameters; when printing starts, the high-speed inkjet printing equipment control system first according to The set random position parameter generation method generates random position parameter coordinates x, y, and calculates the image data storage location corresponding to the random position parameter coordinates as the address for data reading. The control system starts from the address obtained by calculation, reads the data of a set width image, and further processes it according to the arrangement of the imaging components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com