Plasma electric arc additional material device and method

A plasma arc and arc technology, used in plasma welding equipment, additive processing, arc welding equipment, etc., can solve the problems of poor printing shape accuracy and slag splashing, and achieve the effect of improving printing speed and avoiding slag splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

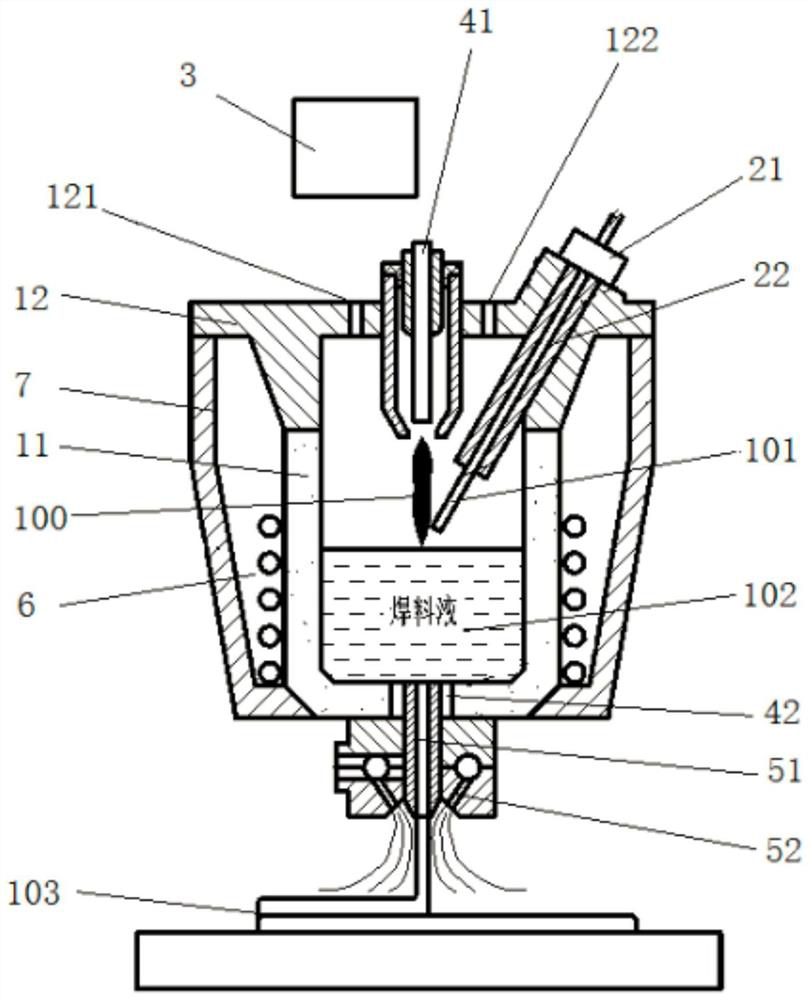

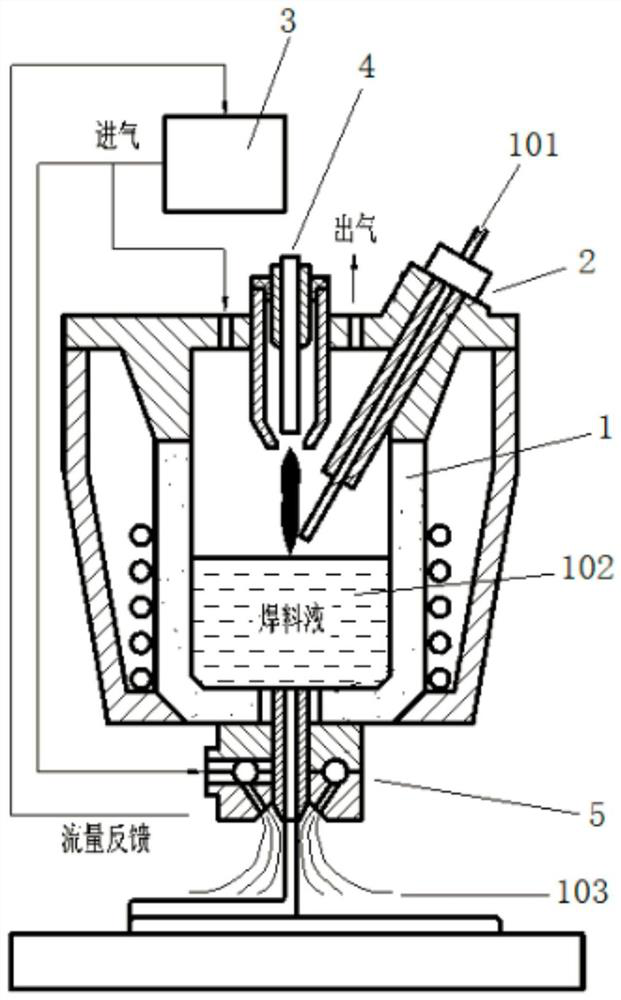

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0029] Such as Figures 1 to 2 As shown, a plasma arc additive device includes,

[0030] Furnace body 1, used to contain molten metal;

[0031] A wire feeding mechanism 2, which is arranged on the furnace body 1 for feeding the metal wire material 101 into the furnace body 1;

[0032] Gas delivery mechanism 3, which is used to deliver gas into the furnace body 1;

[0033] The arc generating mechanism 4 includes a positive electrode 41 and a negative electrode 42 disposed opposite to the furnace body 1, and an arc zone 100 is formed between the positive electrode 41 and the negative electrode 42 to melt the wire material into a molten metal 102;

[0034] The discharging mechanism 5 is arranged at the bottom end of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com