Sprinkling nozzle movement mechanism of 3D printer

A 3D printer and motion mechanism technology, applied in the direction of additive processing, etc., can solve the problems of insufficient adhesion of printed objects, low printing flexibility, affecting molding accuracy, etc. The effect of print speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

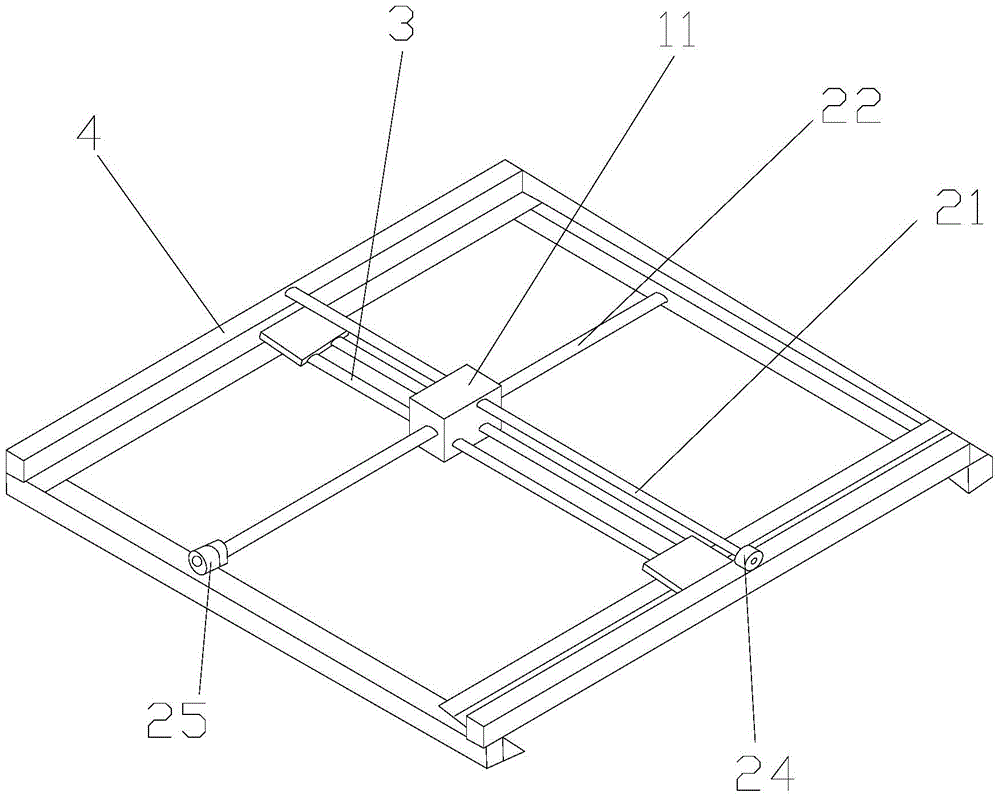

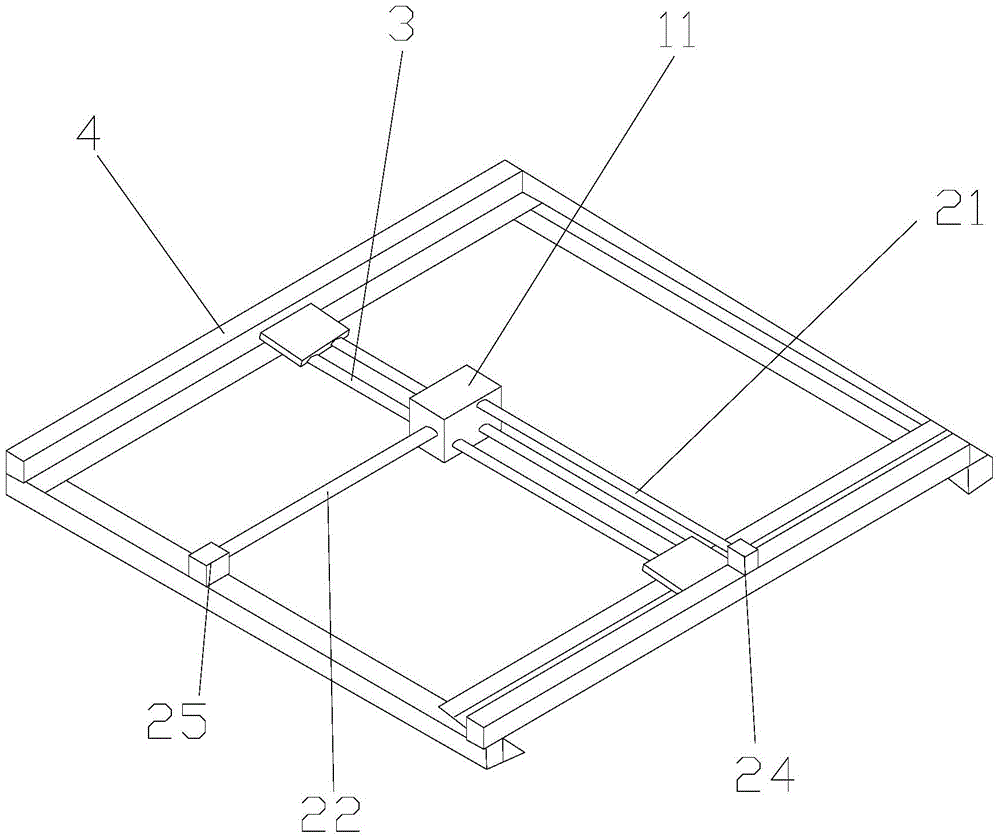

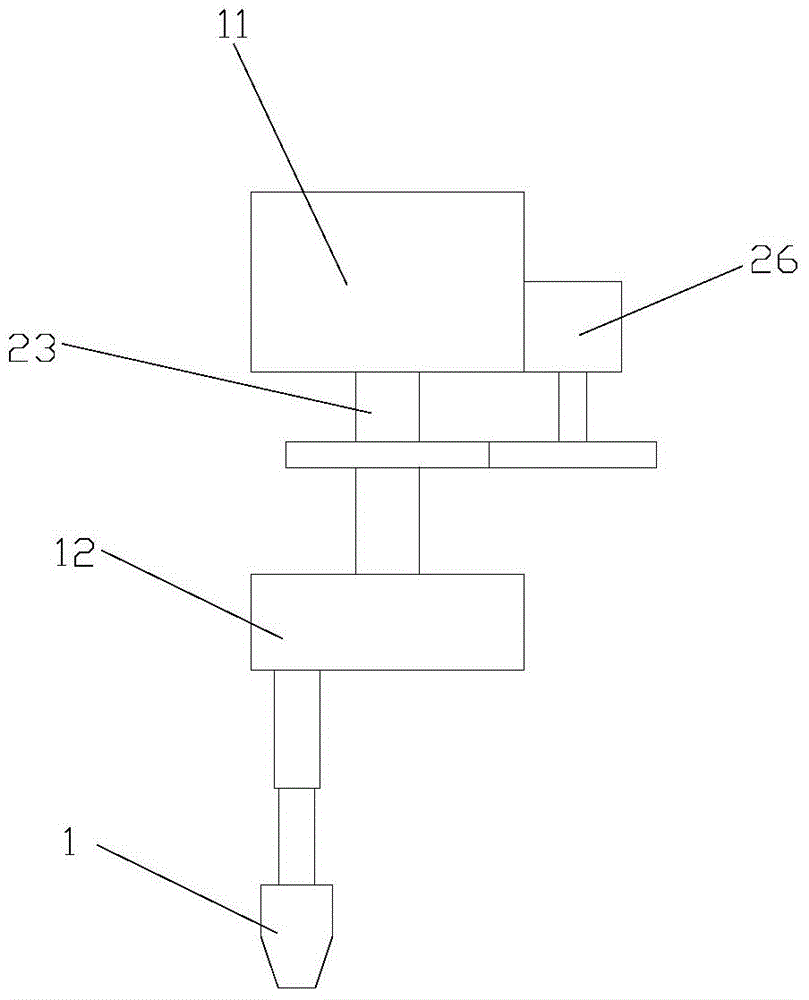

[0018] like figure 1 , figure 2 , image 3 as shown, figure 1 A structural schematic diagram of a 3D printing nozzle proposed by the present invention; figure 2 It is a structural schematic diagram of another embodiment of the nozzle movement mechanism of a 3D printer proposed by the present invention; image 3 It is a schematic diagram of the connection structure of the nozzle in the nozzle movement mechanism of a 3D printer proposed by the present invention.

[0019] refer to figure 1 , figure 2 , image 3 , a nozzle movement mechanism of a 3D printer proposed by the present invention includes a nozzle 1, a first nozzle connector 11, a first transmission mechanism 21, a first drive mechanism 24, a second transmission mechanism 22, a second drive mechanism 25, a first Three transmission mechanisms 23 and a third drive mechanism 26;

[0020] The first spray head connector 11 is installed on the frame 4 of the 3D printer through the sliding mechanism 3, wherein the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com