Automatic adhesive paper pasting equipment

A technology of laminating equipment and adhesive tape, which is applied in metal processing, electrical components, printed circuit manufacturing, etc., can solve problems such as low accuracy, poor manual placement accuracy, and oversized equipment, so as to improve production efficiency and ensure The effect of cleanliness and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

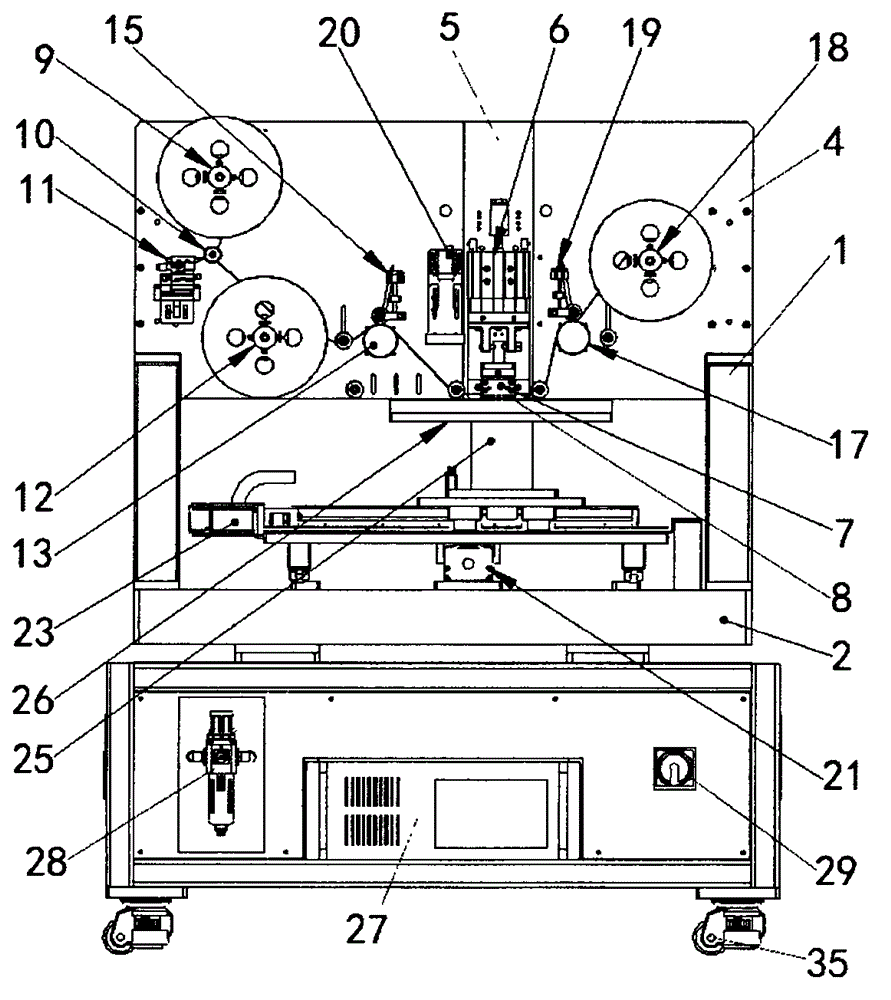

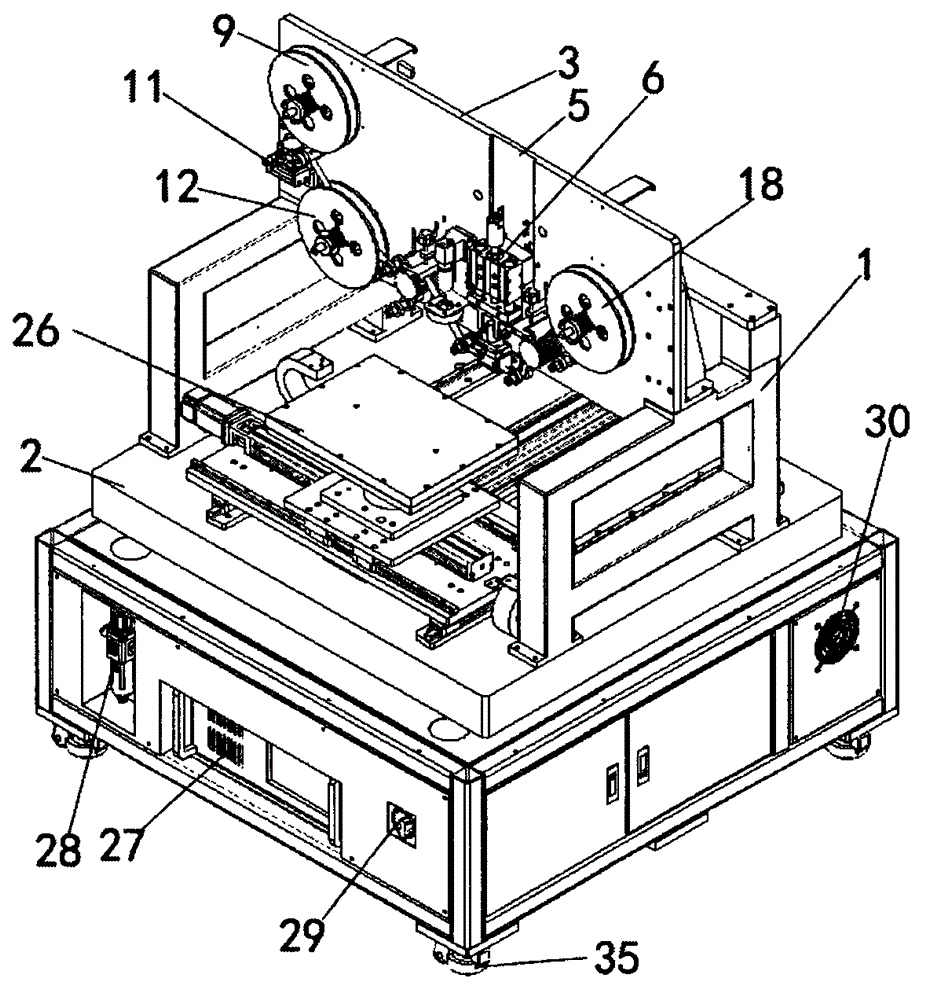

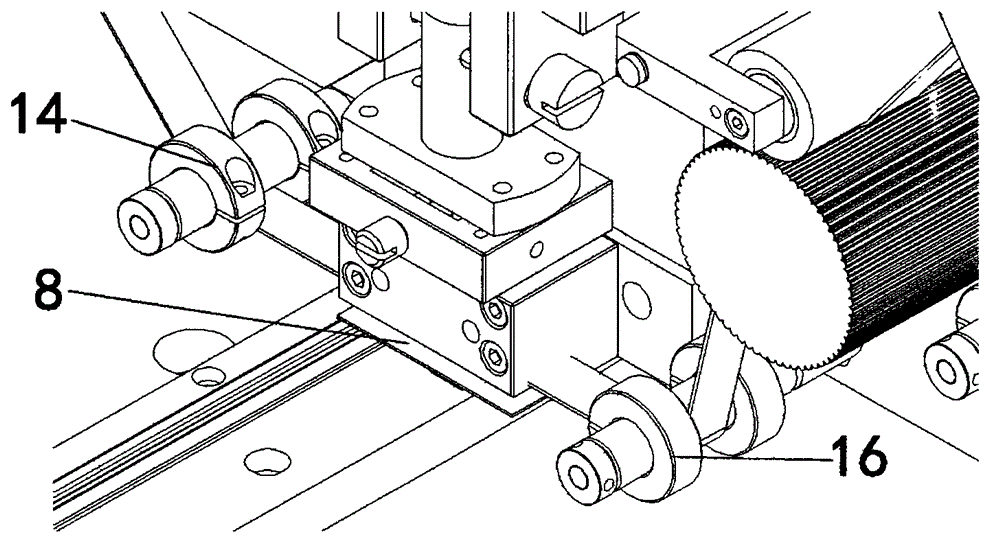

[0058] Embodiment 1: as figure 1 , figure 2 As shown in the figure, an automatic adhesive tape laminating equipment includes a lower control mechanism and an upper operating mechanism.

[0059] The upper operating mechanism includes a steel frame 1, an operating platform 2, and an upper machine cover 3.

[0060] The steel frame 1 is arranged on the operation platform 2 . Wherein the steel frame 1 is arranged along the left, rear and right sides of the operating platform 2.

[0061] A vertical template 4 is fixed on the steel frame 1 . Wherein the template 4 is vertically installed on the steel frames 1 on the left and right sides.

[0062] The template 4 is provided with a vertical groove 5 . The groove 5 is basically arranged in the middle of the template 4 .

[0063] A punching die set 6 capable of moving up and down is installed in the groove 5 . The punching die set 6 is a punching cylinder die set. The cylinder module includes a cylinder, and a connecting piece for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com