Camera assembling adjusting and calibrating method

A calibration method and camera technology, applied in image communication, TV, color TV parts, etc., can solve the problems of inconsistent performance indicators of different cameras, low aiming and positioning accuracy, etc., reduce after-sales maintenance and rework costs, and have strong practicability , The effect of improving interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Camera adjustment and calibration method, including the following steps:

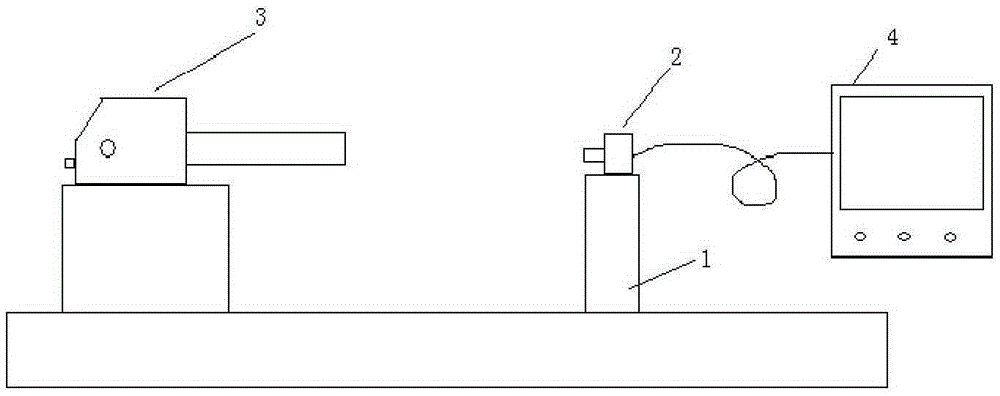

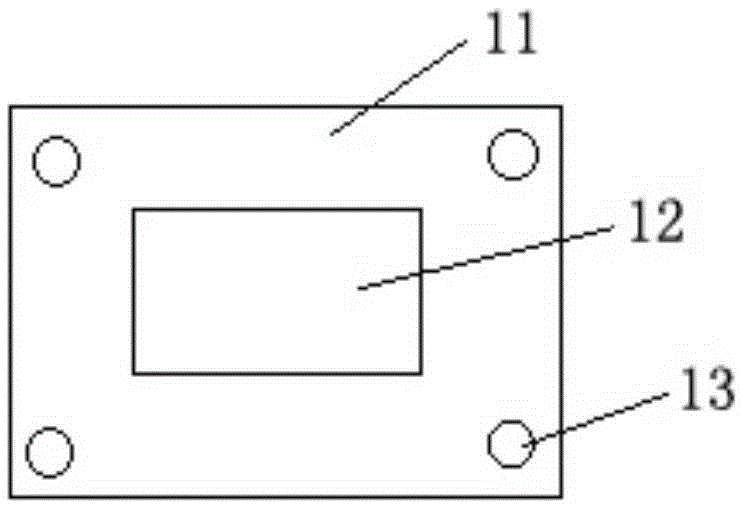

[0022] 1) if figure 1 As shown, the bracket 1 for fixing the camera 2 is correspondingly provided with positioning pins matched with the installation base of the camera 2, and the camera 2 which has been preliminarily assembled (the lens part has been assembled and is fixed on the front of the camera) is fixed by using the positioning pins. on bracket 1;

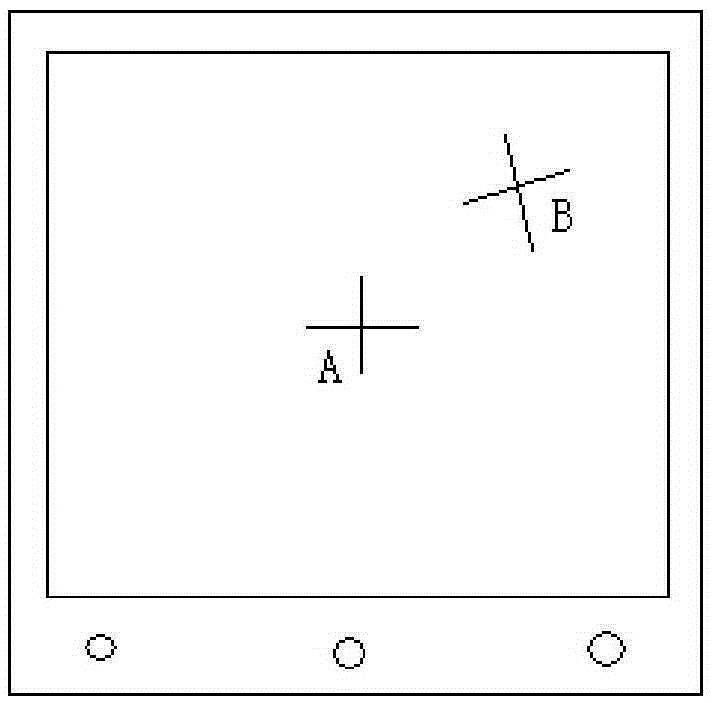

[0023] Place an autocollimator 3 directly opposite the camera 2, roughly align the camera 2, turn on the autocollimator 3 and send out the calibration laser, since the outermost lens of the camera 2 is a filter, directly fine-tune the autocollimation The instrument 3 (such as pitch angle, left and right offset angle, etc.) makes the adjustment laser return along the original optical path through the filter, that is, the optical axis of the autocollimator 3 is perpendicular to the front filter of the lens of the camera 2, that is, The optical ...

Embodiment 2

[0030] Camera adjustment and calibration method, the operation is basically the same as embodiment 1. Since the outermost part of the camera lens is not a filter, in step 1), it is necessary to install a high-precision flat reflector on the front reference surface of the camera lens, and then fine-tune the autocollimator (such as pitch angle, left and right offset angle, etc.), Make the adjustment laser return along the original optical path through the plane reflector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com