Calibration device for discrete optical axis multispectral alignment instrument

The technology of a calibration device and a calibration instrument, which is applied in the field of optical metrology, can solve the problems of a multispectral calibration instrument that cannot calibrate discrete optical axes, and that the calibration instrument does not have a self-calibration function, and achieves objective calibration results and simple calibration methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

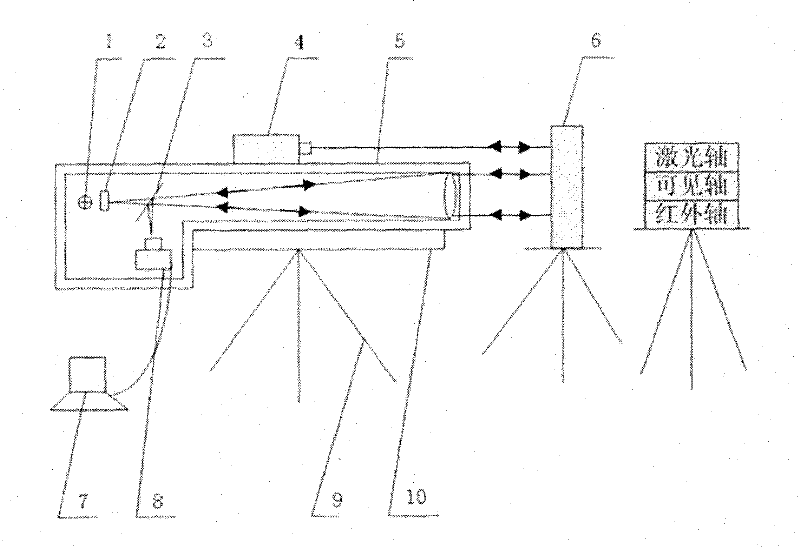

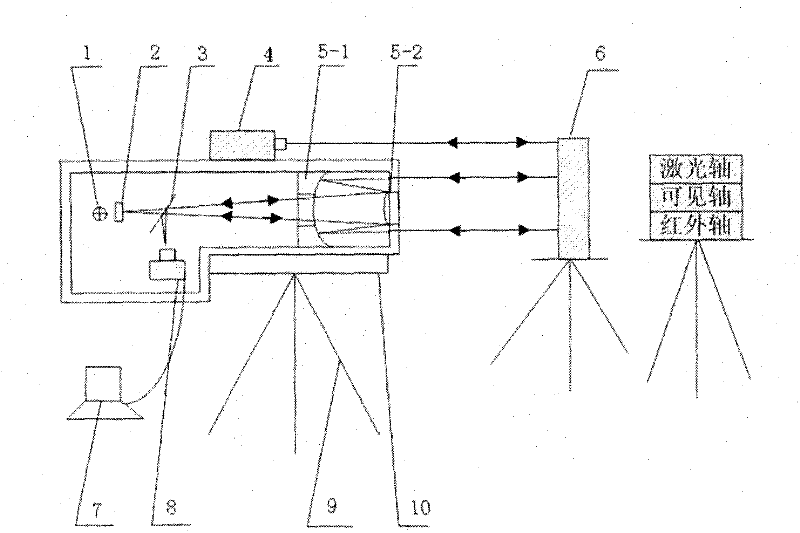

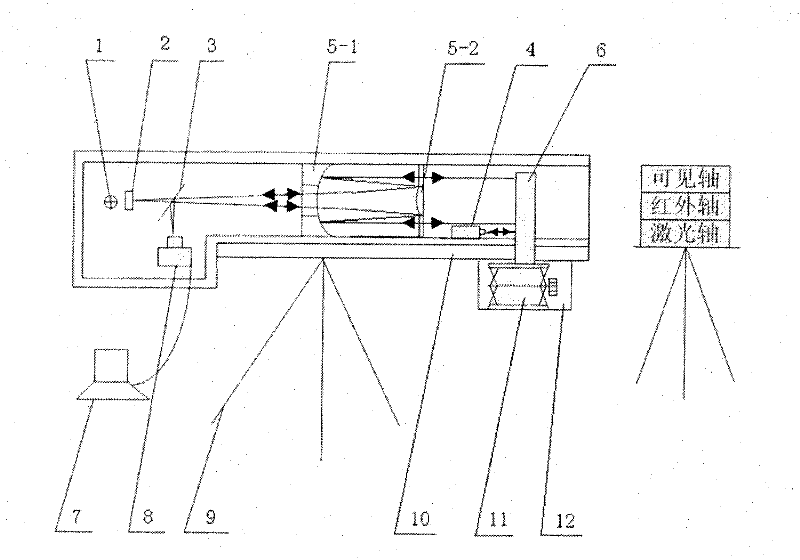

[0012] see figure 1 , The calibration device of the first preferred embodiment of the present invention includes a collimator 5, a half mirror 3, a laser 4, a plane mirror 6, a display 7, a CCD camera 8, a tripod 9 and a system support frame 10. The collimator 5 includes a light source 1, a target 2 and an objective lens. The light source 1 is a tungsten halogen lamp; the objective lens is a double glue objective lens. The target 2 is made of zinc sulfide material capable of transmitting visible and infrared light. Draw. The collimator 5 is fixed on the system support frame 10 , and the system support frame 10 is installed on the tripod 9 . The caliber of the collimator 5 should be able to simultaneously accommodate the infrared and visible light channels of the measured alignment instrument. Both the half mirror 3 and the CCD cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com