Shock wave time calibration device and method for shock test

A time calibration and impact test technology, applied in the field of impact compression loading, can solve the problems of limited ignition peak pressure of gunpowder and small adjustment range of projectile speed, and achieve the effect of convenient calibration method, simple device structure, and reliable and effective experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

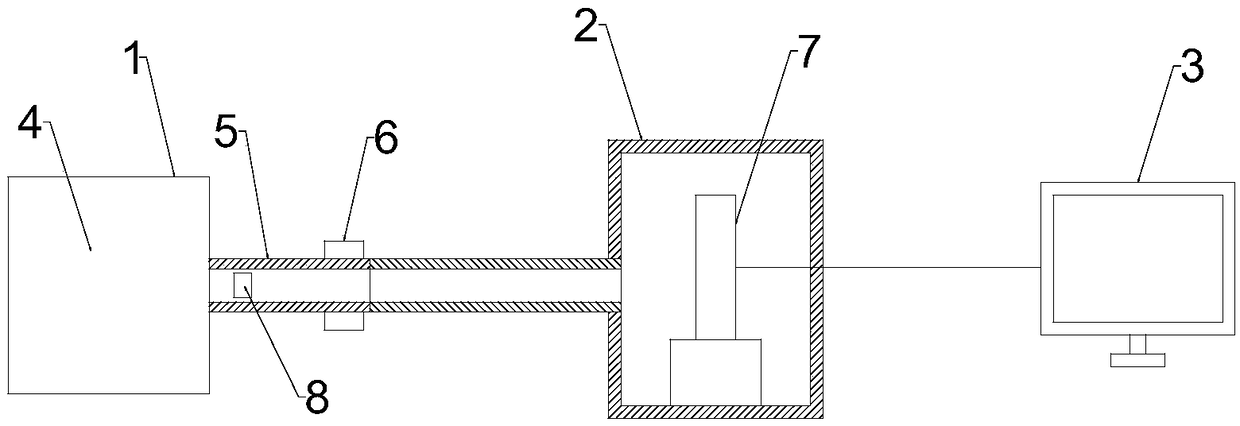

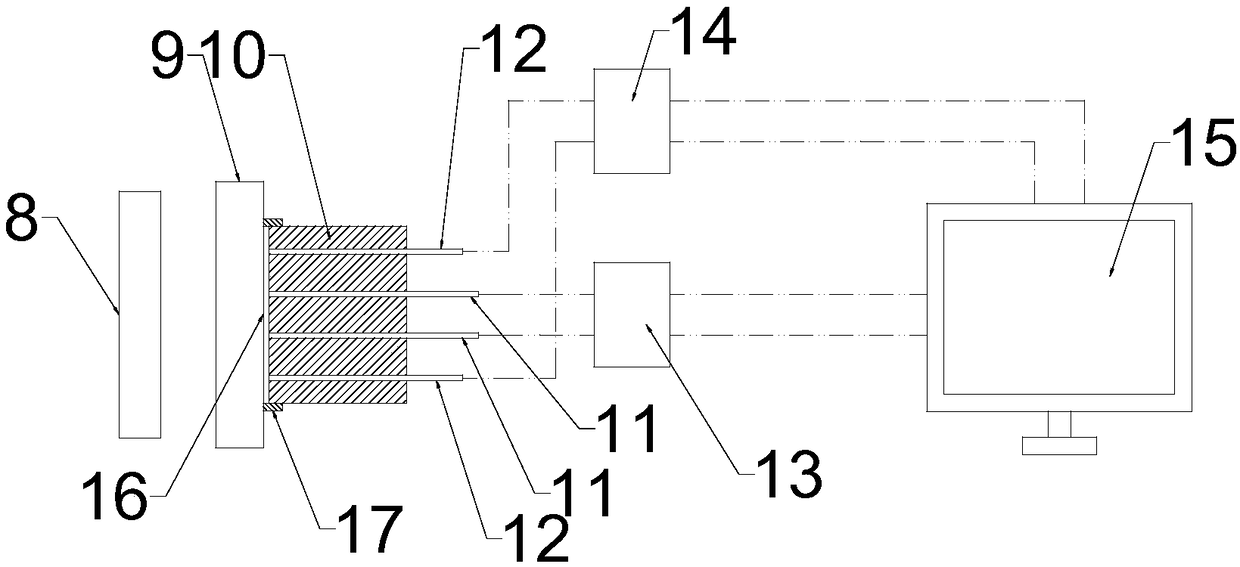

[0028] A shock wave time calibration device for shock testing, such as figure 1 and figure 2 As shown, it includes a controllable high-speed emission device 1, a target chamber 2, and a signal collection device 3. The target chamber 2 is a vacuum target chamber, and an experimental target 7 is arranged in the target chamber 2. The experimental target 7 includes a substrate 9, Fixed column 10, at least one optical probe 11, and at least two electrical probes 12, the fixed column 10 is arranged on the right side wall of the substrate 9 (of course, the fixed column 10 can also be arranged on the left side of the substrate 9 On the side wall, when it is arranged on the left side wall of the substrate 9, the follow-up controllable high-speed launching device 1 is used to drive the right side wall of the flying piece 8 impacting the substrate 9.), the substrate 9 and the fixed column 10 is provided with a light-emitting gap 16, one end of the optical probe 10 and one end of the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com