Stokes polarization meter error calibration and compensation method based on wave plate rotating method

A technology of rotating wave plate and error calibration, which is applied in the direction of measuring the polarization of light, instruments, scientific instruments, etc., and can solve the problems that the size of the error source cannot be calculated and the calibration process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the drawings.

[0034] Since the error calibration and compensation method of the Stokes polarimeter proposed in the present invention is based on related theoretical formulas, the theoretical derivation process is first introduced in detail, and then the error calibration and compensation method of the Stokes polarimeter is introduced in detail.

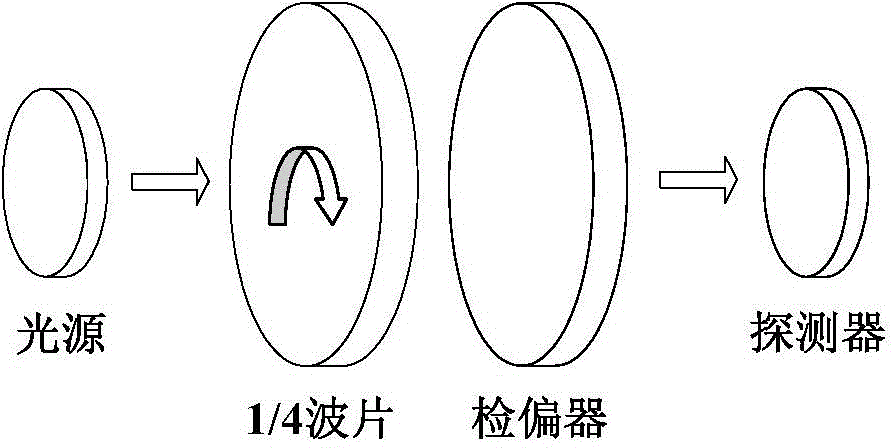

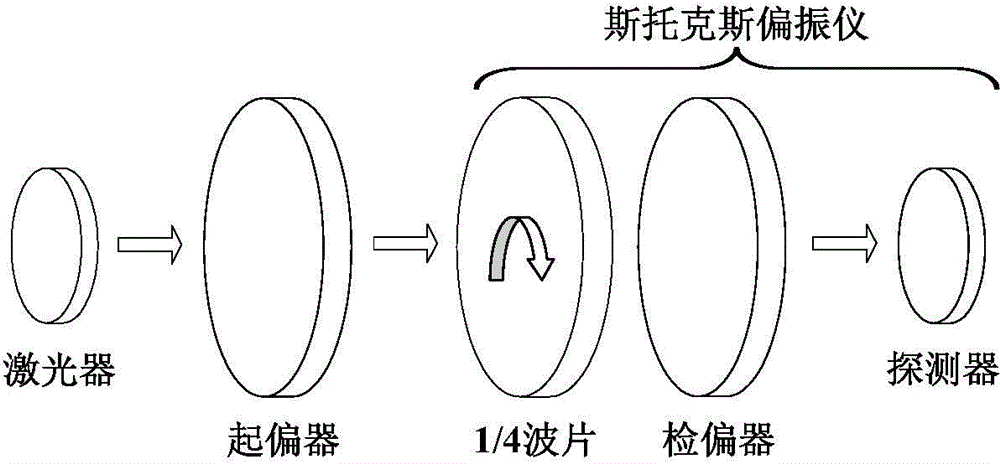

[0035] figure 1 It is a schematic diagram of the Stokes polarimeter structure based on the rotating wave plate method. The Stokes polarimeter is mainly composed of a rotatable quarter-wave plate, a fixed analyzer and a photodetector. figure 1 The light source in can be a polarized illumination light source, or any natural scene that requires polarization detection. Rotating wave plate measurement method means that by rotating the wave plate to N specified azimuth angles, the photodetector obtains the light intensity value of the emitted light at each azimu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com