Printed circuit board virtual manufacturing system of electronic design automation of electronic product and realization method thereof

A technology of virtual manufacturing system and electronic products, applied in computing, electrical digital data processing, special data processing applications, etc., can solve problems such as PCB board physical parameter errors, assemblability errors, etc., to save time and production costs, shorten The effect of reducing the manufacturing cycle and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

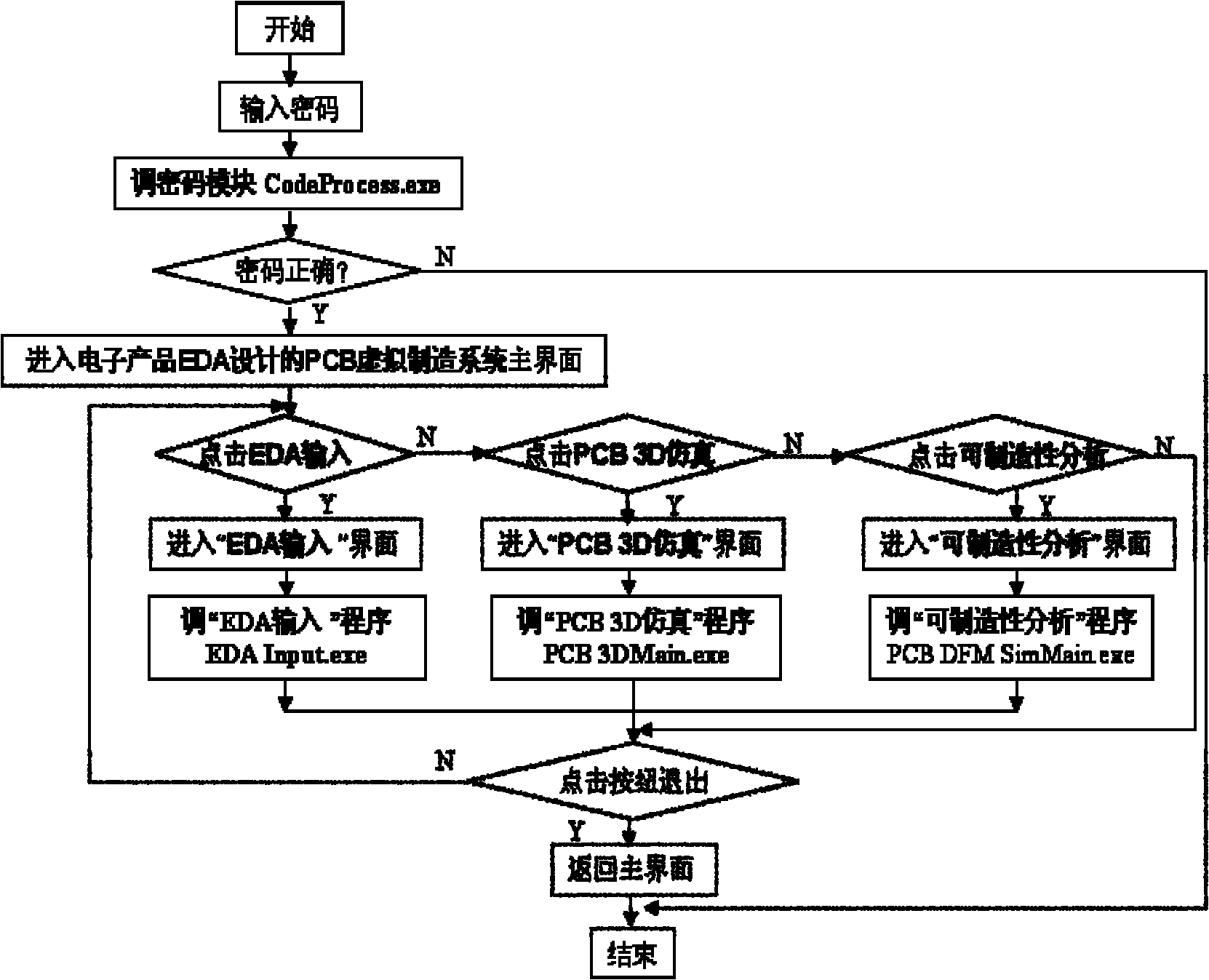

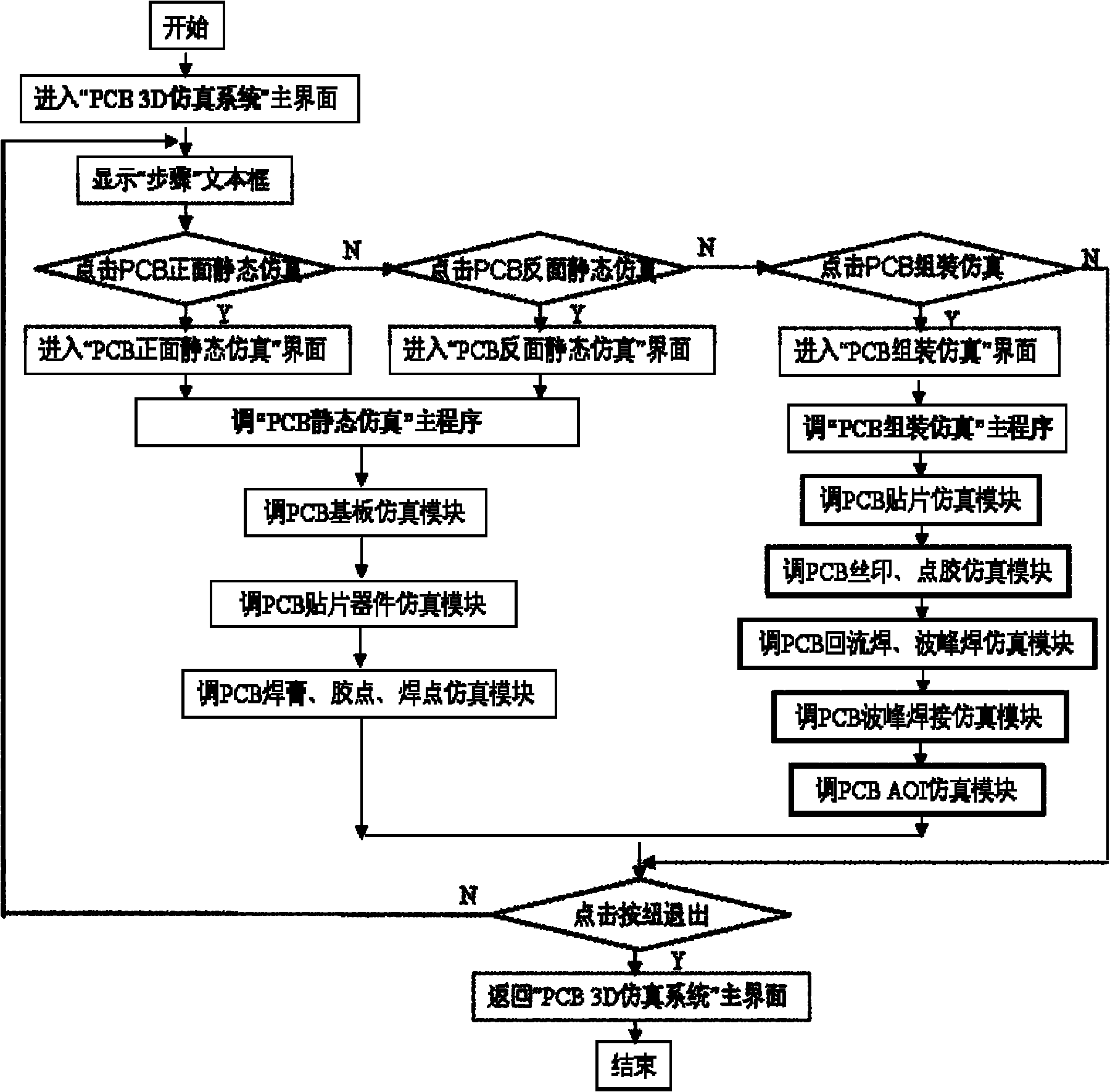

[0021] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

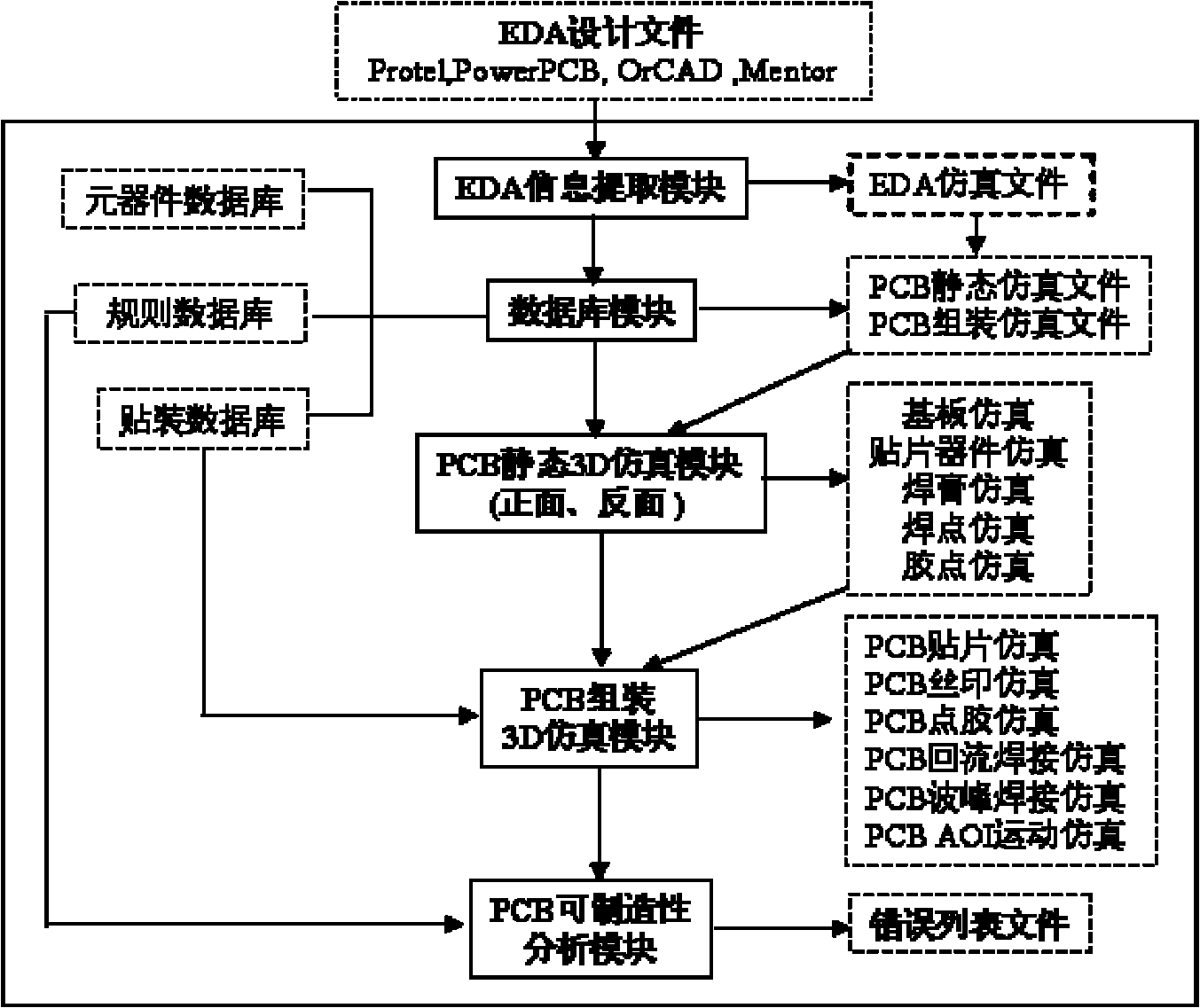

[0022] This embodiment is a kind of PCB virtual manufacturing system designed by electronic product EDA, such as figure 1 The system structure shown includes:

[0023] 1) EDA information extraction module: read in the EDA design file, extract the information and discrimination parameters of PCB board design from it, save it as a Chinese EDA simulation file in a unified format, and input the data into the database;

[0024] 2) PCB static and assembly 3D simulation module: According to the simulation information extracted from the EDA information extraction module, the simulation model of the virtual manufacturing system is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com