Multi-axis numerical-control machine tool processing precision retaining ability optimization method based on robust design

A technology of CNC machine tools and machining accuracy, applied in the direction of digital control, program control, comprehensive factory control, etc., can solve the problem of rare optimization design of machine tool machining accuracy retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

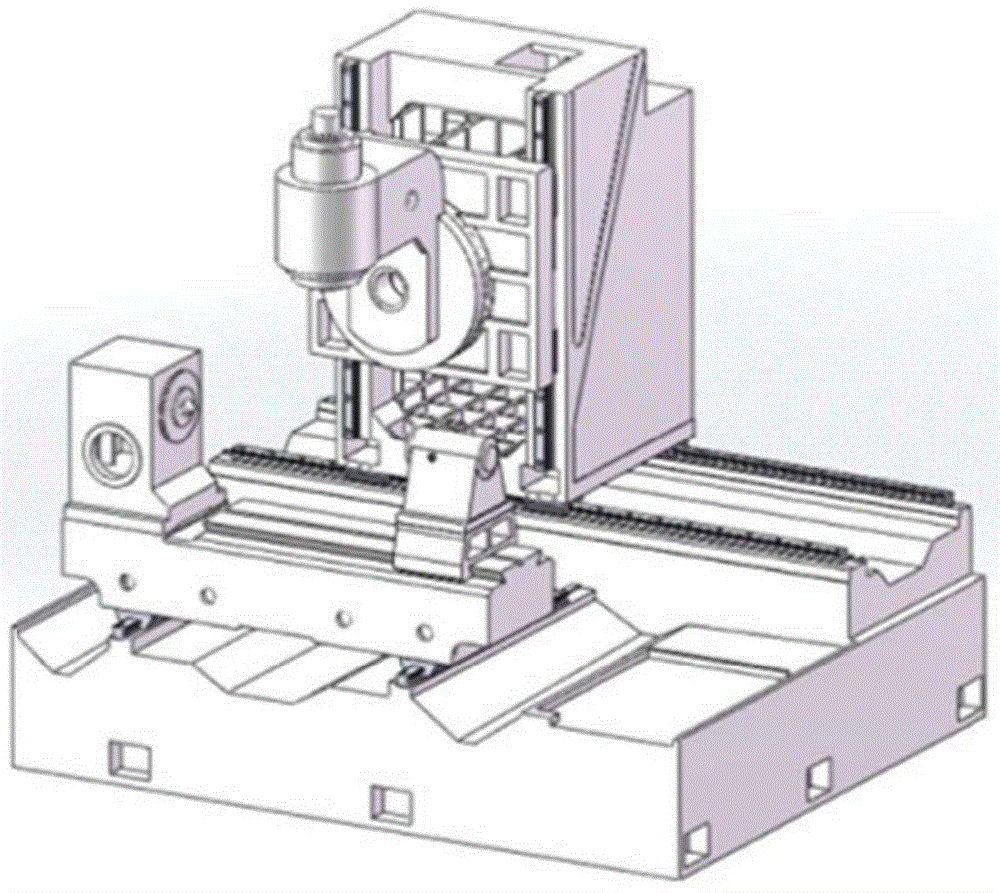

[0089] The present invention takes the XKH1600 five-axis machining center as an example to verify the geometric error distribution method of the above-mentioned multi-axis numerical control machine tool.

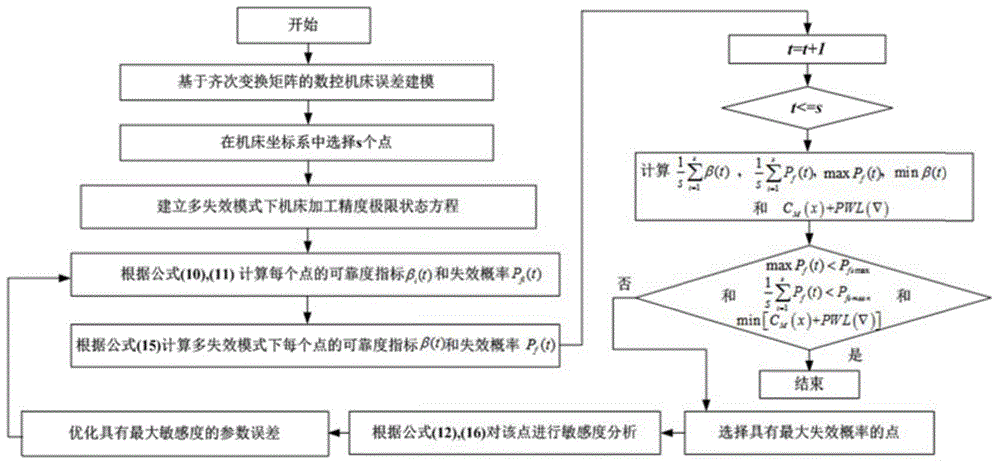

[0090] Specifically include the following steps:

[0091] Step 1 Take the five-axis CNC machine tool as an example to establish the spatial error model of the machine tool.

[0092] Using the HTMs method to establish the spatial error model of the machine tool;

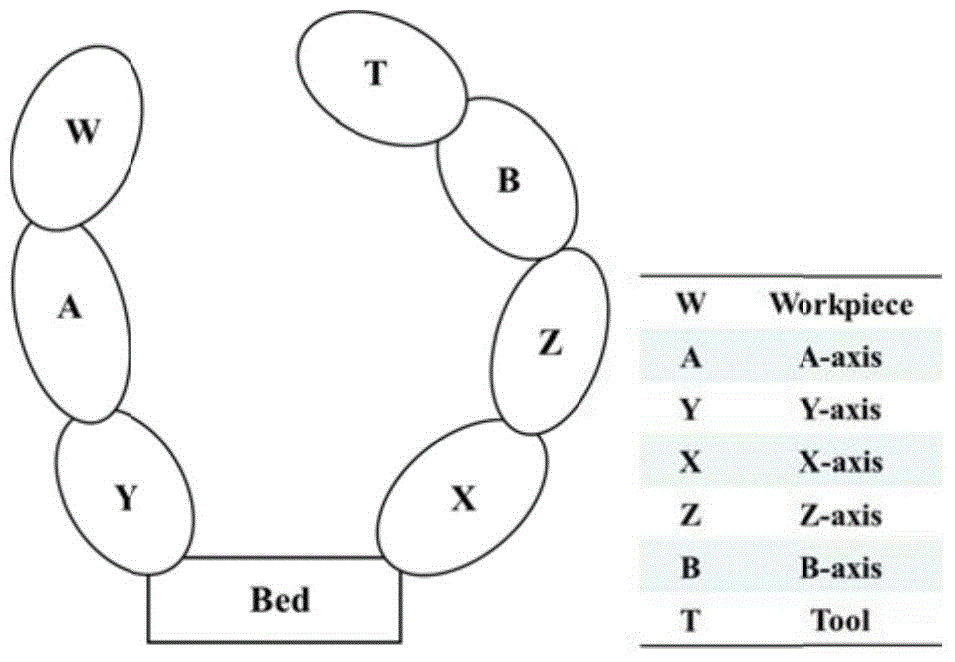

[0093] Step 1.1 Establish geometric error model of five-axis CNC machine tool

[0094] The HTMs method is applied to establish the geometric error model of the machine tool to obtain the relationship between various errors among different parts of the machine tool. In this paper, the model of XKH1600 five-axis CNC machine tool is taken as an example to analyze the geometric error and establish the geometric error model. The five-axis machining center processes blades and is equipped with three linear axes X, Y, Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com