A second-level process simulation method for hot strip rolling

A technology of process simulation and hot continuous rolling, applied in the direction of contour control, etc., can solve problems such as the inability to guarantee the quality of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

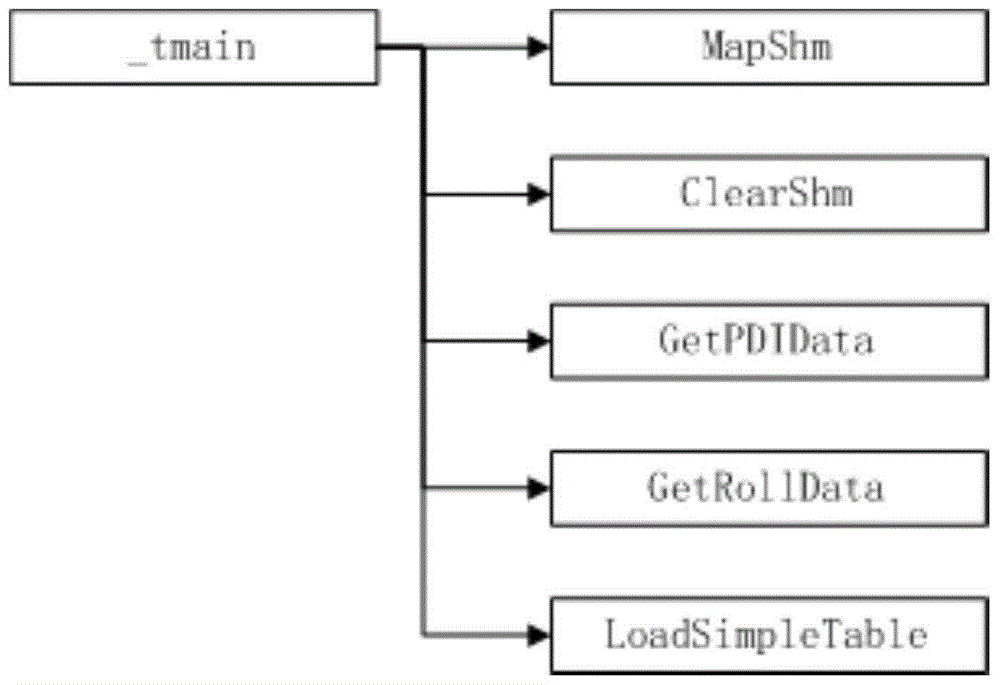

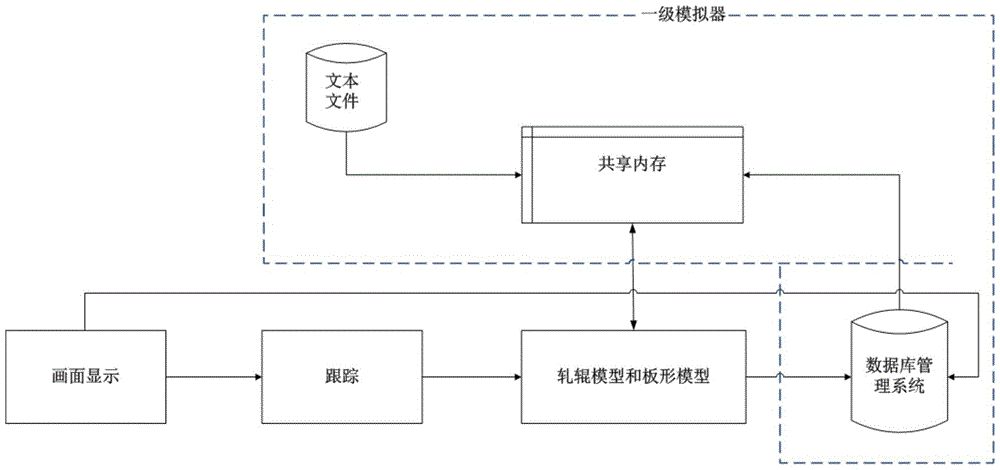

[0027] In the specific implementation process, a second-level process simulation method for hot continuous rolling strip shape is described. Based on a set of off-line platform, the method simulates the calculation process of the hot continuous rolling secondary shape model, and accurately reproduces the on-site continuous rolling process.

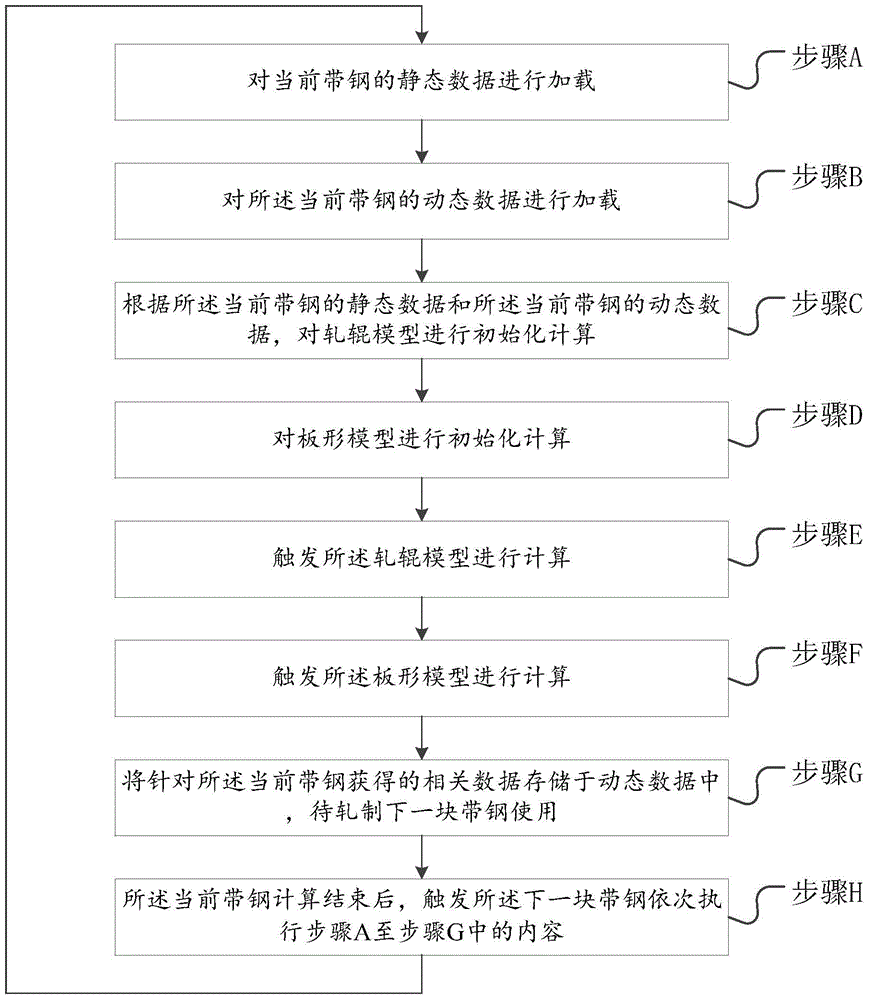

[0028] See below figure 1 , is the flowchart of the second-level process simulation method for hot strip shape.

[0029] The method comprises the steps of:

[0030] Step A, loading the static data of the current steel strip.

[0031] Specifically, the current static data of the steel strip includes properties of the steel type, characteristics of the stand, parameters of the roll, primary data, instrument measurement data, and secondary setting parameters.

[0032] Step B, loading the dynamic data of the current steel strip.

[0033] Specifically, the dynamic data of the current strip is the relevant data obtained after rolling the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com