Asynchronous roller alternating control method for hot continuous rolling downstream rack working rollers

A control method and work roll technology, which is applied in the roll shifting control of the downstream stand of hot continuous rolling and finishing rolling, and in the field of strip rolling, can solve the problems of unfavorable product index stability, fluctuation, and overall stability of unfavorable product control index, etc. To achieve the effect of optimizing convexity and wedge index, suppressing wedge and deviation, and avoiding the superposition of severe wear area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

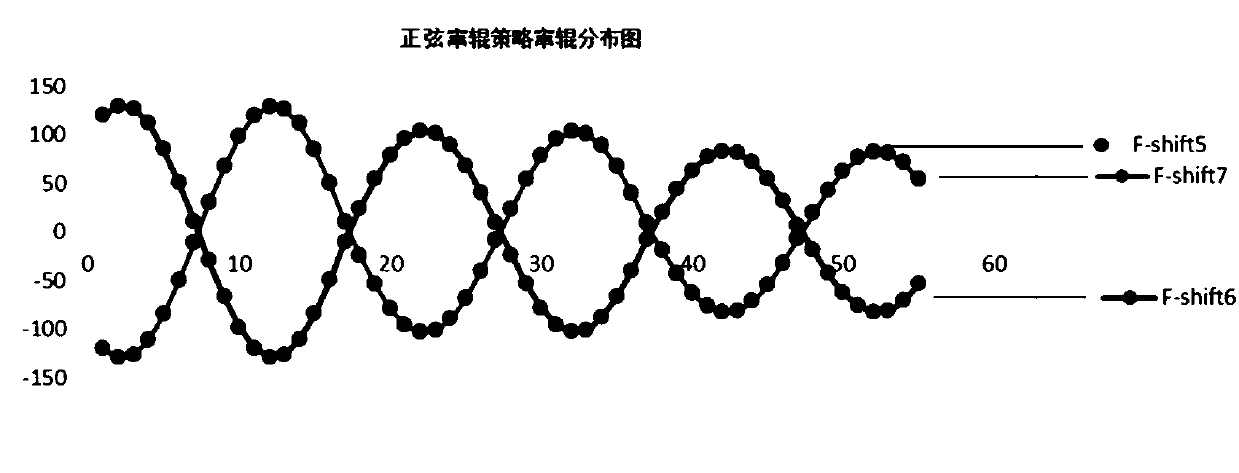

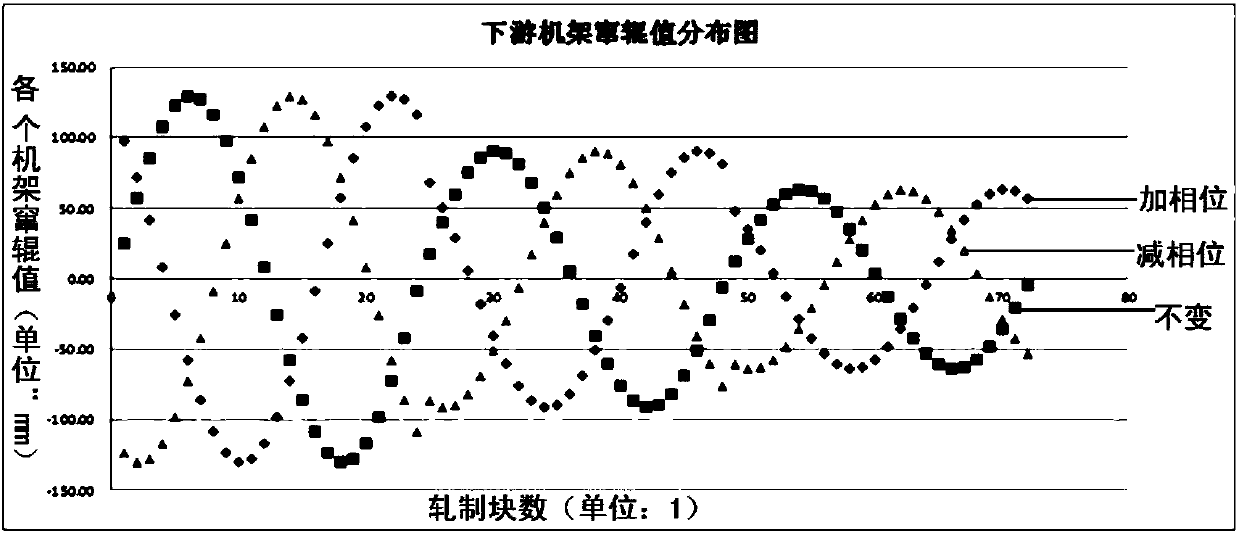

[0039] In order to understand the present invention in depth, taking the most advanced single-period variable-step roll shifting strategy (also known as sinusoidal roll shifting strategy) as an example, how to perform asynchronous operation between downstream racks is specifically described.

[0040] Such as figure 1 - figure 2 As shown, the method of the present invention includes the asynchronous coefficient q, the number of asynchronous blocks t, and the number of rolled blocks in the first cycle t 0 and maximum roll shifting stroke L m Four parameters.

[0041] Among them, q is an asynchronous coefficient, which is used to represent the degree of asynchrony between each rack, and the unit is 1;

[0042] t is the number of asynchronous blocks, which is used to implement the value of asynchronous phase into the roll shifting function, and the unit is 1;

[0043] t 0 is the number of rolling blocks in the first roll shifting cycle, the unit is 1;

[0044] L m is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com