Method for optimizing rolling scope of hot strip rolling

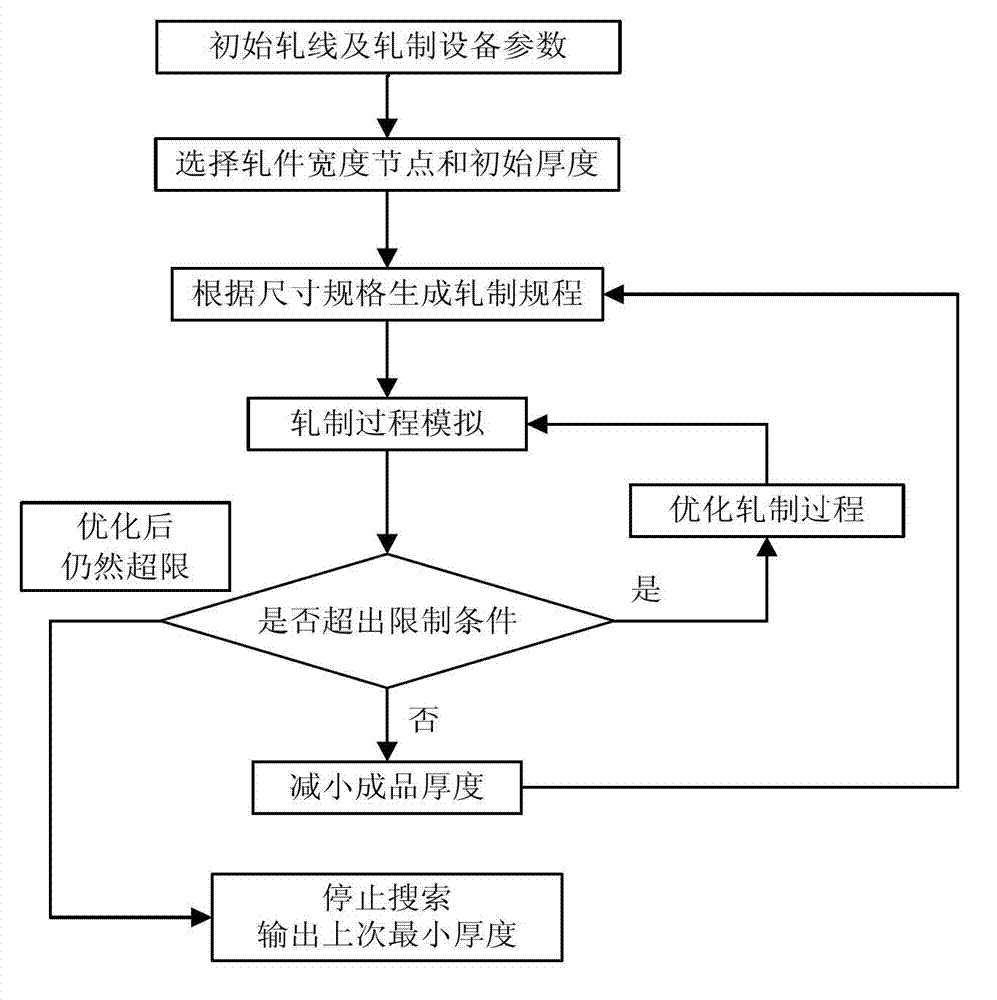

An optimization method, hot continuous rolling technology, applied in the direction of metal rolling, etc., can solve the problems of the rolling capacity of the rolling mill, the error of the rolling range, and the high energy consumption of rolling, etc., to achieve calculation and optimization, and save production Cost and reduction of rolling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

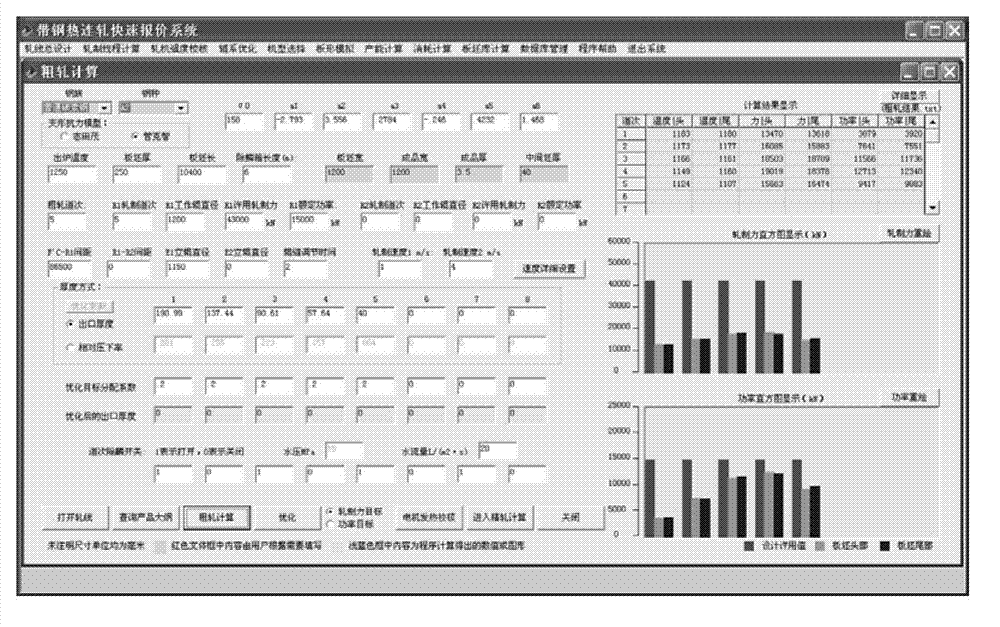

[0058] According to the flow of the invention, a visual operating software is written to realize the automatic calculation of the rollable range. Based on the equipment and process requirements of a certain 1580 rolling line, the limit rolling specifications of austenitic 304 stainless steel and ferritic 430 stainless steel were calculated. The specific implementation methods are as follows:

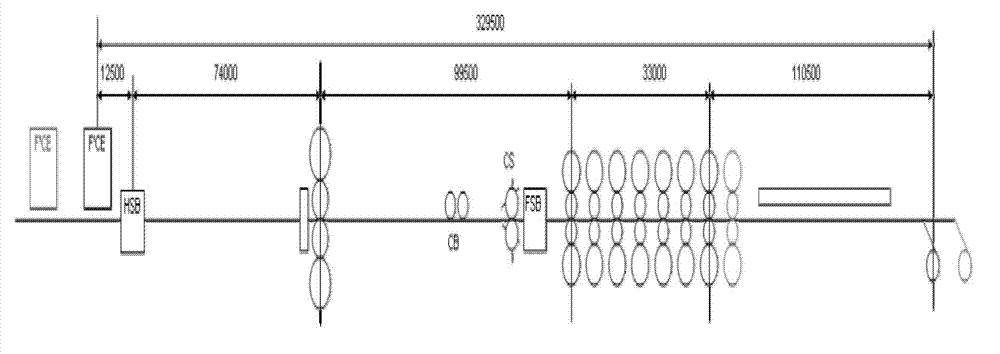

[0059] 1. Initial parameter setting

[0060] Rolling line layout parameters such as figure 2shown. The main equipment of the designed 1580 rolling line consists of a walking heating furnace (another position is reserved), roughing descaling box (HSB), vertical roller edger (E1), four-roll roughing mill (R1), Hot coil box (CB), flying shear (CS), finishing descaling machine (FSB), finishing unit (F1~F7, and reserve F8 position), laminar cooling layer (reserved position), one underground Coiler (another position is reserved). The total length of the rolling line is 329.5 meters.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com