Water-based hot rolling liquid containing nano TiO2 and preparation method thereof

A rolling liquid and nano technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor corrosion and rust resistance of steel, harsh production environment, polluted cooling water, etc., and achieve good surface quality and long anti-corrosion period , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

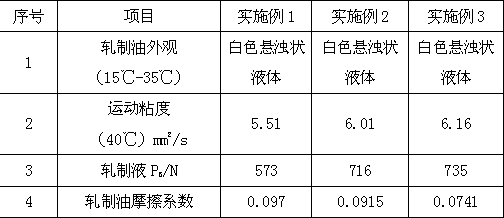

Examples

Embodiment 1

[0014] Embodiment 1 formula sees the following table:

[0015] serial number component name weight (g) 1 Nano Titanium Dioxide 0.2 2 Hexametaphosphate 0.5 3 SDBS 1.0 4 Triethanolamine 1.0 5 isothiazolinone 0.5 6 Glycerol 10.0 7 benzotriazole 0.5 8 Deionized water 85.3

[0016] According to the weight formula of each component in the above table, add deionized water, sodium hexametaphosphate, sodium dodecylbenzenesulfonate, triethanolamine, isothiazolinone, glycerol and benzotriazole in sequence, and put Put it in a reaction kettle with a rotation speed of 80-120 rpm for heating and stirring. When the temperature reaches 60°C, add nano-titanium dioxide, keep warm and continue stirring for 30 minutes, then stop heating and continue stirring to room temperature to obtain a white suspension liquid , That is to make the required water-based rolling liquid. The rolling liquid of...

Embodiment 2

[0018] Embodiment 2 formula sees the following table:

[0019] serial number component name weight (g) 1 Nano Titanium Dioxide 0.5 2 Hexametaphosphate 1.0 3 SDBS 2.0 4 Triethanolamine 2.0 5 isothiazolinone 0.8 6 Glycerol 12.0 7 benzotriazole 0.6 8 Deionized water 81.1

[0020] Add deionized water, sodium hexametaphosphate, sodium dodecylbenzenesulfonate, triethanolamine, isothiazolinone, glycerol and benzotriazole in sequence according to the formula in the above table, and put it in the Heating and stirring in the reactor at 120 rev / min, when the temperature reaches 60°C, add nano-titanium dioxide, keep warm and continue to stir for 30 minutes, then stop heating and continue to stir to room temperature to obtain a white suspension liquid, which is promptly made into the required Water-based rolling liquid, the rolling liquid of this formula has obvious stratification afte...

Embodiment 3

[0022] Embodiment 3 formula sees the following table:

[0023] serial number component name weight (g) 1 Nano Titanium Dioxide 1.0 2 Hexametaphosphate 2.0 3 SDBS 3.0 4 Triethanolamine 2.0 5 isothiazolinone 1.0 6 Glycerol 10.0 7 benzotriazole 1.0 8 Deionized water 80.0

[0024] According to the weight formula of each component in the above table, add deionized water, sodium hexametaphosphate, sodium dodecylbenzenesulfonate, triethanolamine, isothiazolinone, glycerol and benzotriazole in sequence, and put Put it in a reaction kettle with a rotation speed of 80-120 rpm for heating and stirring. When the temperature reaches 60°C, add nano-titanium dioxide, keep warm and continue stirring for 30 minutes, then stop heating and continue stirring to room temperature to obtain a white suspension liquid , but according to formula 3, a large amount of TiO will appear after the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com