Setting control method of hot continuous rolling steel coil marking machine

A control method and number spraying technology, which is applied to typewriters, printing, printing devices, etc., can solve problems such as production scheduling, warehouse management difficulties, and steel coil warehouse management, shipment and coil finding, etc., to achieve a high degree of printing automation and content Rich and diverse printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Setting control method of hot continuous rolling steel coil marking machine

[0026] The setting and control method of the hot-rolled steel coil numbering machine in this example includes a set of methods for setting the hot-rolled steel coil numbering software and controlling the hot-rolled steel coil numbering machine to spray hot-rolled steel coils. The setting control method of the hot continuous rolling steel coil numbering machine in this example is the setting control method of the hot continuous rolling steel coil numbering machine controlled by the computer system, and it is a link in the computer management and control of the automatic and modern production of the hot continuous rolling steel coil. Therefore, the multi-functional and automatic numbering machine for hot continuous rolling steel coils has been realized. The specific realization of the setting control method of the hot continuous rolling steel coil numbering machine in this example ...

Embodiment 2

[0029] Embodiment 2. Setting control method of hot continuous rolling steel coil marking machine

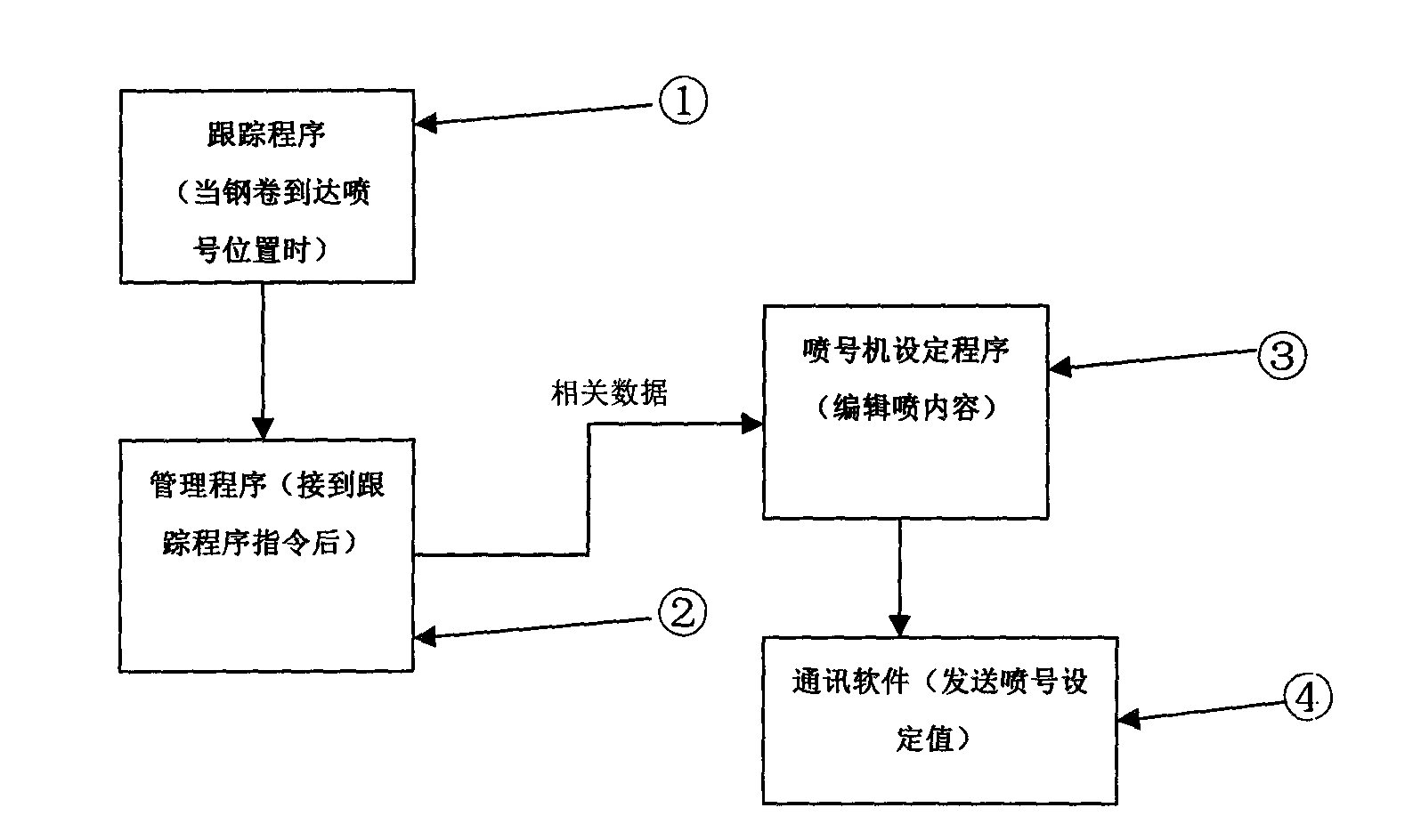

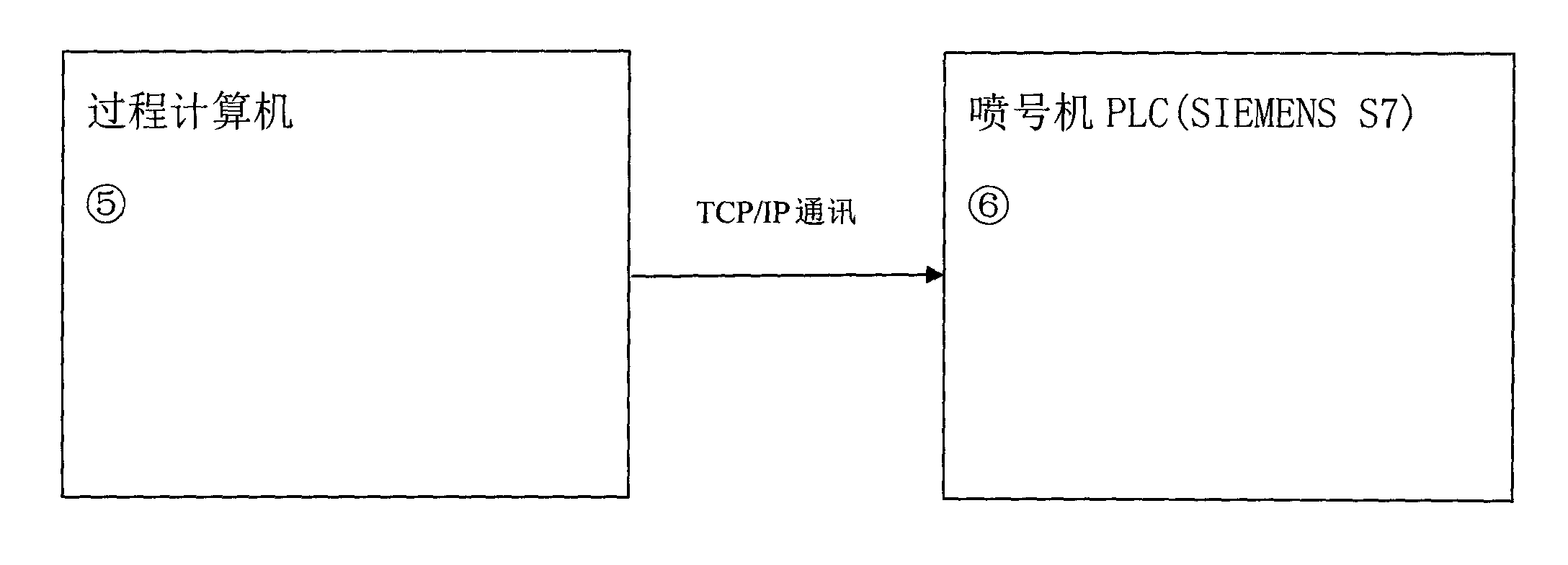

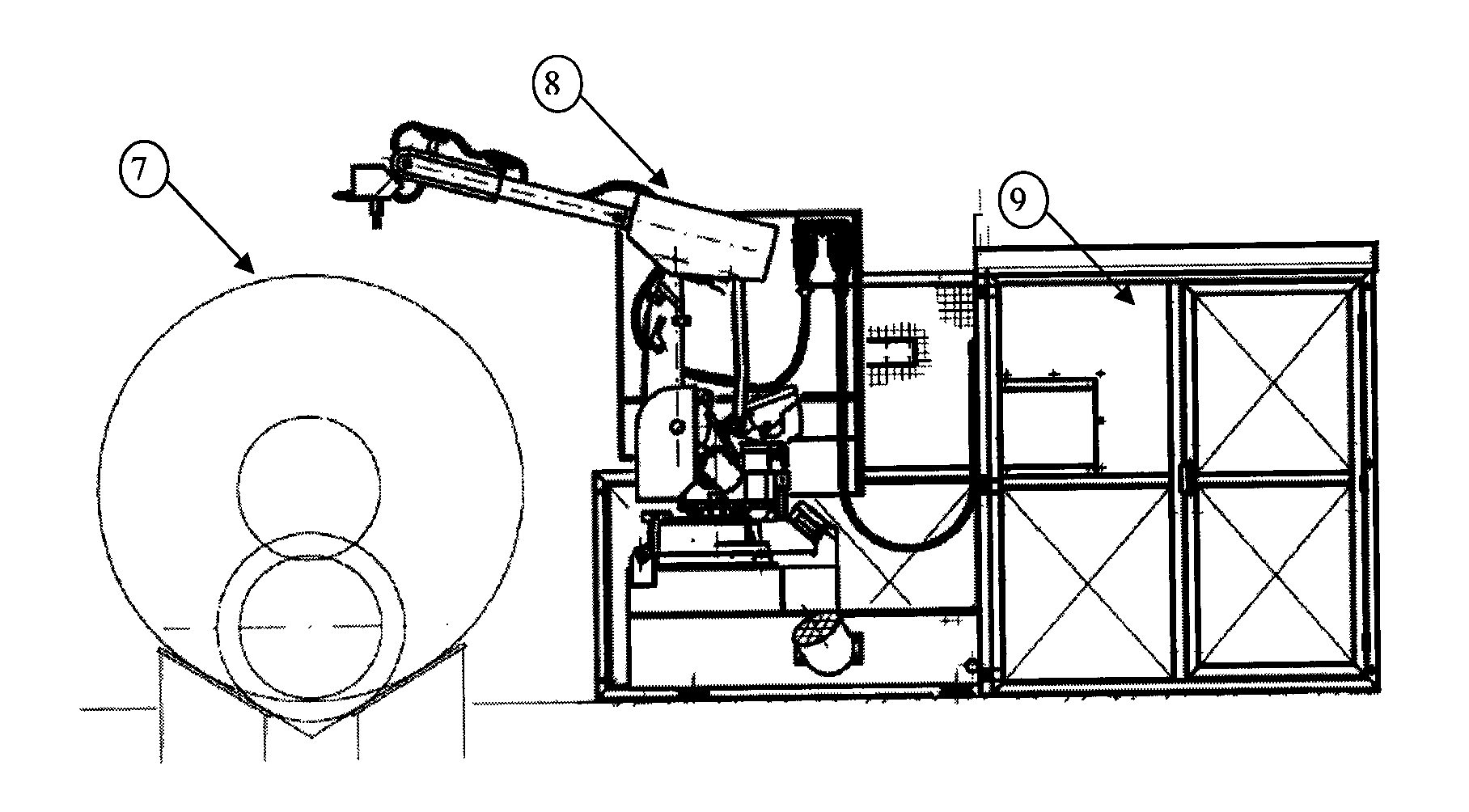

[0030] The general structure of the setting control method of the hot continuous rolling steel coil marking machine can be used Figure 1 to Figure 5 etc. jointly show that the setting control method of the hot continuous rolling steel coil numbering machine of this example is different from the setting control method of the hot continuous rolling steel coil numbering machine of Embodiment 1: 1. The editing of the steel coil numbering machine in this example The editing or collection of software is the collection and input of the steel coil number spraying information: the collection and input of the steel coil spray number information in this example is completed by the man-machine dialogue mechanism of the front-end computer 5, such as keyboard, handwriting input, voice Input, U disk or CD input, etc. 2. The storage subsystem of the pre-stage computer 5 of this example can als...

Embodiment 3

[0031] Embodiment 3. Setting control method of hot continuous rolling steel coil marking machine

[0032] The general structure of the setting control method of the hot continuous rolling steel coil marking machine can be used Figure 1 to Figure 5etc. jointly show that the setting control method of the hot continuous rolling steel coil numbering machine of this example is different from the setting control method of the hot continuous rolling steel coil numbering machine of embodiment one and embodiment two: 1. the steel coil of this example The editing or collection of the coil spray number editing software is the editing and generation of the steel coil spray number information: the editing and generation of the steel coil spray number information in this example is edited and generated by the front-end computer 5 according to the data setting, or automatically determined and generated according to the data tracking. These methods of editing and generating based on data set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com