Endless hot rolling method of high grade steel

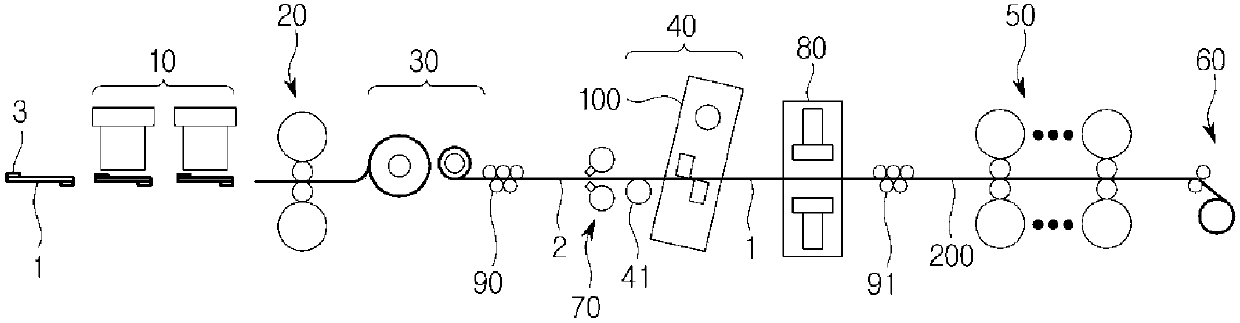

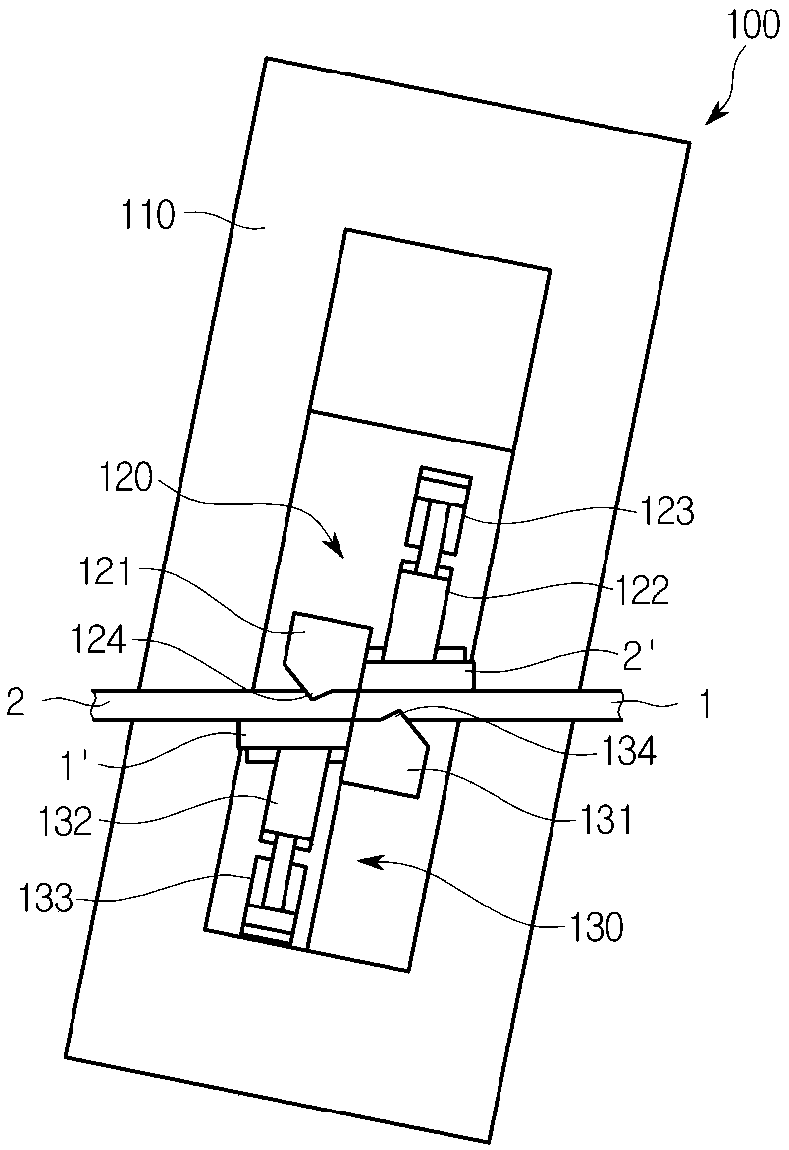

A hot continuous rolling, high-grade steel technology, applied in metal rolling and other directions, can solve the problems of inability to ensure the pass through, reduce the joint strength ratio, minimize bending deformation, prevent process obstruction, and improve rolling through the plate. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

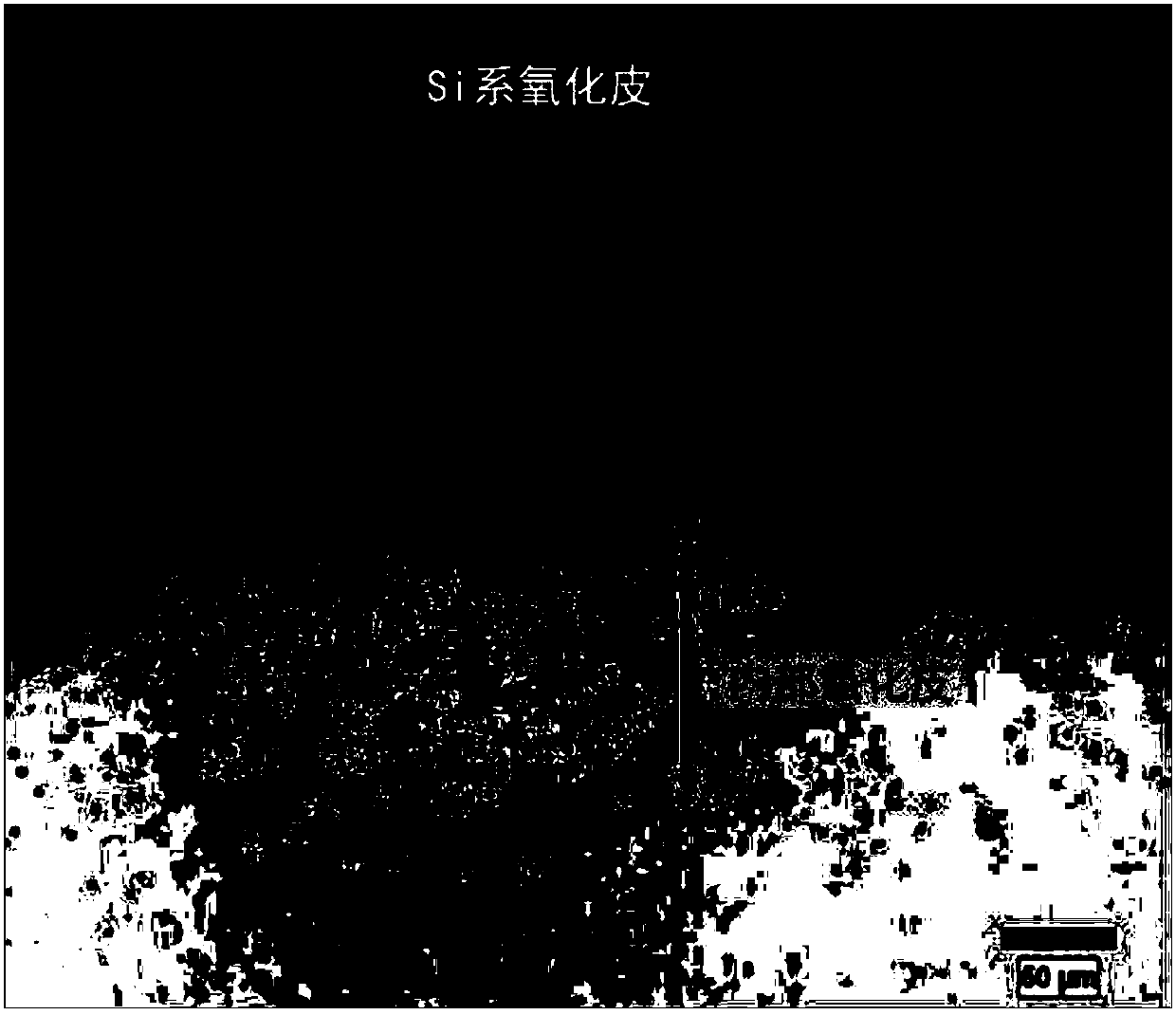

[0146] Using a welding wire containing 80% iron powder and 20% fluorite powder as flux, 80% Ar and 20% CO 2 Used as a shielding gas, using 280A current, 30V voltage, 10.5kJ / cm heat input and 480mm / min welding speed, on high carbon steel (S45C) with a thickness of 250mm, a width of 1000mm, and a length of 10000mm One pass of flux-cored arc welding (FCAW) was performed on the shear joint of the billet. Then, an ordinary thin steel plate is arranged on the welded part, and the high-carbon steel slab is reheated and rough-rolled for 1 hour at a temperature of 1250° C., wherein, in weight %, the ordinary thin steel plate contains: Si: 0.2% or less, Cr: 0.2% or less, C: 0.3% or less, Mn: 1.6% or less, Cu: 0.3% or less, P: 0.04% or less, S: 0.04% or less and the balance Fe. Then, shear joining was carried out and finish rolling was performed to manufacture a hot-rolled coil with a total reduction ratio of 90% or more.

Embodiment 1-2

[0148] Metal powder containing 80% iron powder and 20% fluorite powder dissolved in vacuum is sprayed on the shear joint of high-carbon steel (S45C) billets with a thickness of 250 mm, a width of 1,000 mm, and a length of 10,000 mm. At the same time, continuous strip cladding of ordinary thin strip steel, wherein, in weight %, the ordinary thin strip steel contains: Si: 0.2% or less, Cr: 0.2% or less, C: 0.3 % or less, Mn: 1.6% or less, Cu: 0.3% or less, P: 0.04% or less, S: 0.04% or less and the balance Fe. Then, at a temperature of 1250° C., the high-carbon steel slab was reheated and rough-rolled for 1 hour. Then, shear joining was carried out and finish rolling was performed to manufacture a hot-rolled coil with a total reduction ratio of 90% or more.

Embodiment 1-3

[0150] Using a welding wire containing 80% iron powder and 20% fluorite powder as flux, 80% Ar and 20% CO 2 Used as a shielding gas, using 280A current, 30V voltage, 10.5kJ / cm heat input and 480mm / min welding speed, on high carbon steel (S45C) with a thickness of 250mm, a width of 1000mm, and a length of 10000mm One pass of flux-cored arc welding (FCAW) was performed on the shear joint of the billet. Then, at a temperature of 1250° C., the high-carbon steel slab was reheated and rough-rolled for 1 hour. Then, shear joining was carried out and finish rolling was performed to manufacture a hot-rolled coil with a total reduction ratio of 90% or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com