Method for repairing plate of hot strip rolling mill online

A rolling mill archway and steel rolling mill technology, applied in the field of steel rolling machinery, can solve problems such as inability to adapt to fast-paced production and inability to solve, and achieve the effects of shortening the archway repair time, facilitating processing and manufacturing, and achieving quick results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

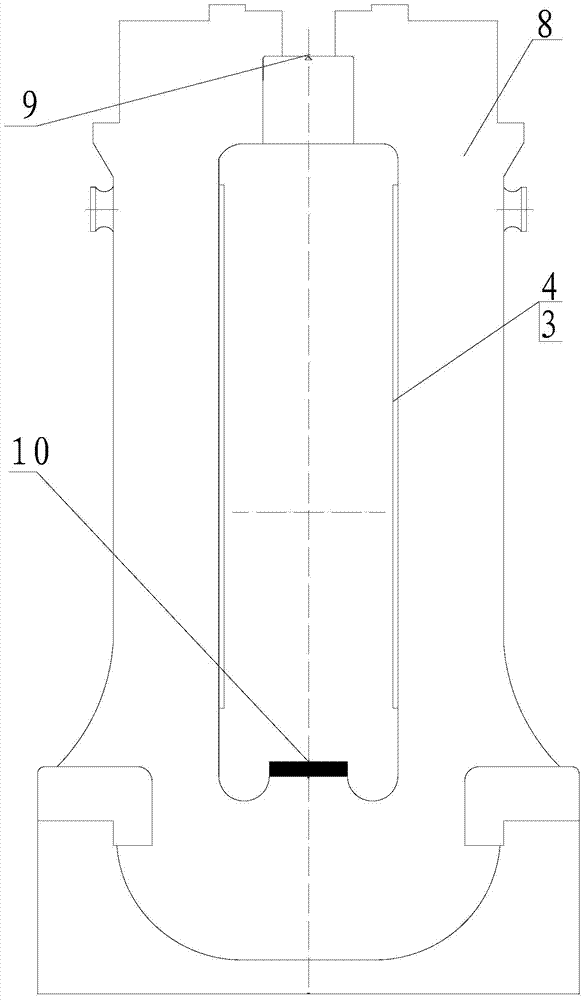

[0134] Embodiment 1 Rolling mill arch repair method of the present invention

[0135] In this embodiment, step 1, step 2, step 3, step 4 and step 5 of the method for repairing the archway of the rolling mill are as described above, and will not be repeated here, and now for the determination in step 3 The frame line method is described in detail.

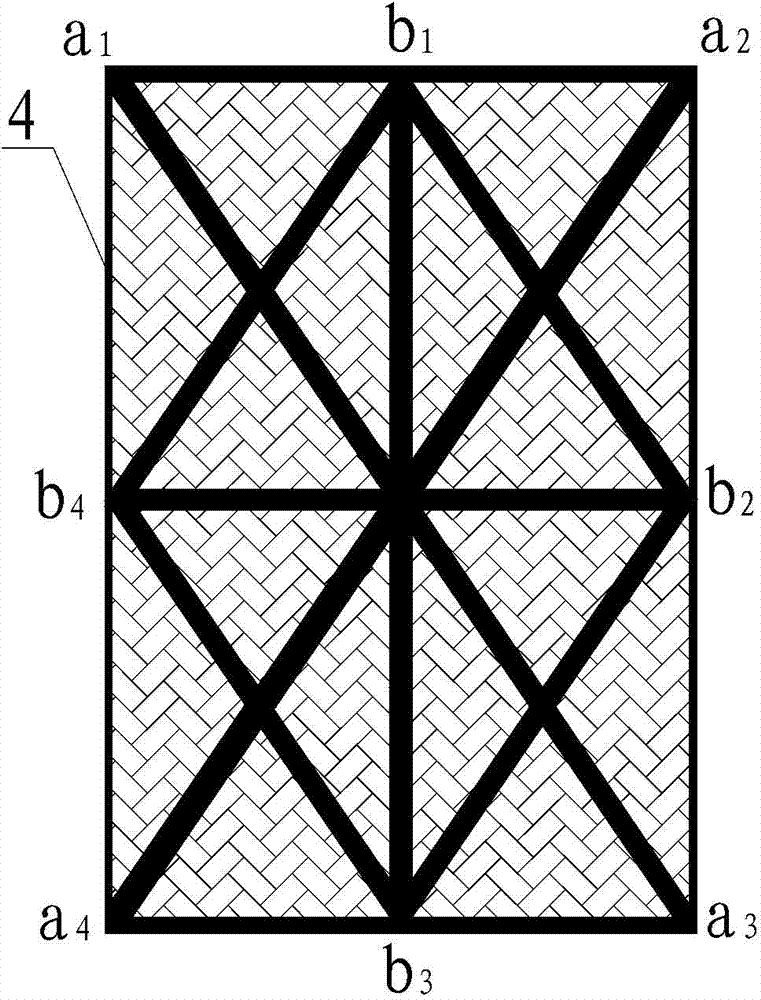

[0136] Frame dash:

[0137] Such as figure 2 As shown, a rectangular frame line is drawn on the surface of the upper archway. The four corners of the rectangular frame line are a1, a2, a3, and a4 respectively, and a1, a2, a3, and a4 occupy the four corners of the upper archway surface to be repaired in turn. , b1, b2, b3, and b4 occupy the midpoint of the a1a2 connection, a2a3 connection, a3a4 connection, and a4a1 connection in turn, a1 and a3 are connected with a dashed line, a2 and a4 are connected with a dashed line, b1, b2, b3, b4 Any two are connected with a scribe line, and all the drawn lines form the upper half of the fr...

Embodiment 2

[0138] Embodiment 2 Rolling mill arch repair method of the present invention

[0139] Only the frame scribing method is different from Example 1, and the others are the same as Example 1.

[0140] Frame dash:

[0141] Draw a rectangular frame line on the surface of the upper archway. The four corners of the rectangular frame line occupy the four corners of the upper archway surface to be repaired in turn, and then divide the rectangular frame line into 16 small rectangles. All the lines drawn Forming the upper half of the frame line; forming the lower half of the frame line in the same manner as forming the upper half of the frame line.

[0142] The repaired rolling mill archway in embodiment 1 and embodiment 2 was put into use again. Under the condition of the same amount of wear, the service life of the rolling mill archway in embodiment 2 was only 80% of the service life of the rolling mill archway in embodiment 1.

[0143] Analysis shows that compared with the prior art,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com