Hot continuous rolling medium-and-heavy plate production method and device without coiling micro-stress

A technology of production equipment and production method, which is applied to the production method and equipment field of coil-free micro-stress hot continuous rolling medium and heavy plate, can solve the problems of not realizing the multi-function of the first line and low production efficiency, and achieve the improvement of efficiency and reduction of production efficiency. Residual stress, the effect of reducing flatness defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

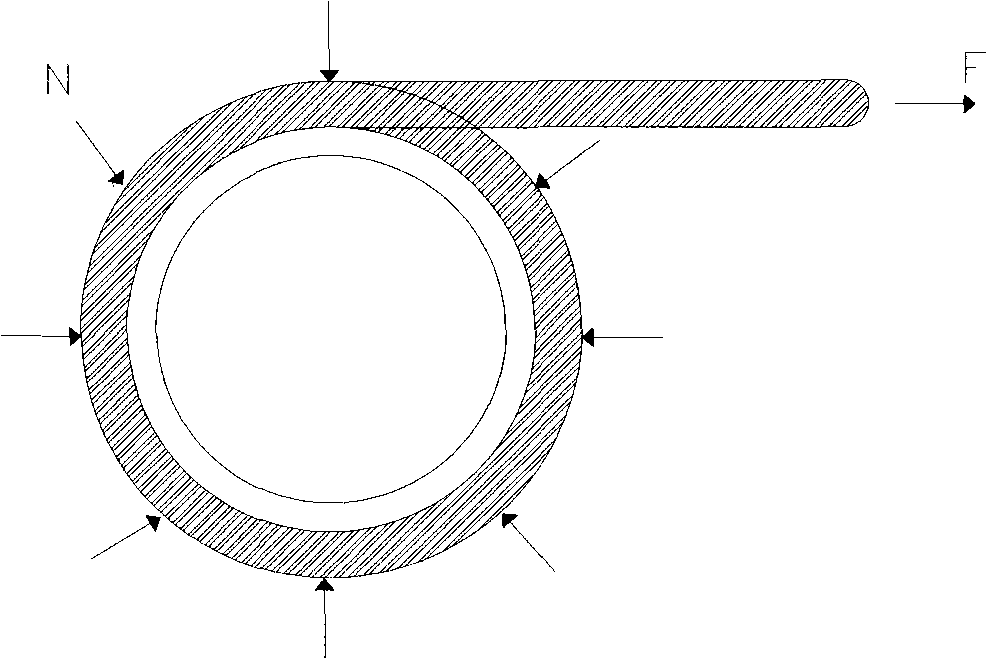

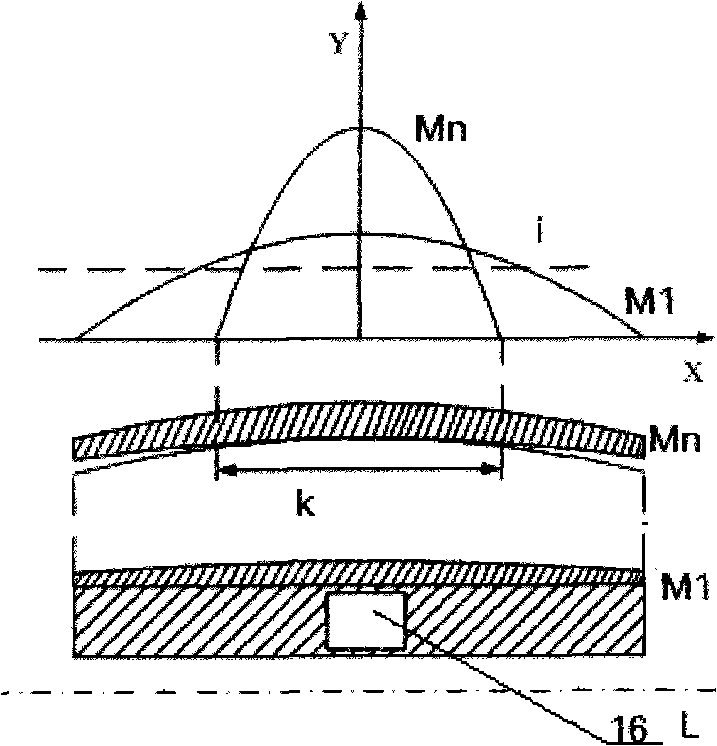

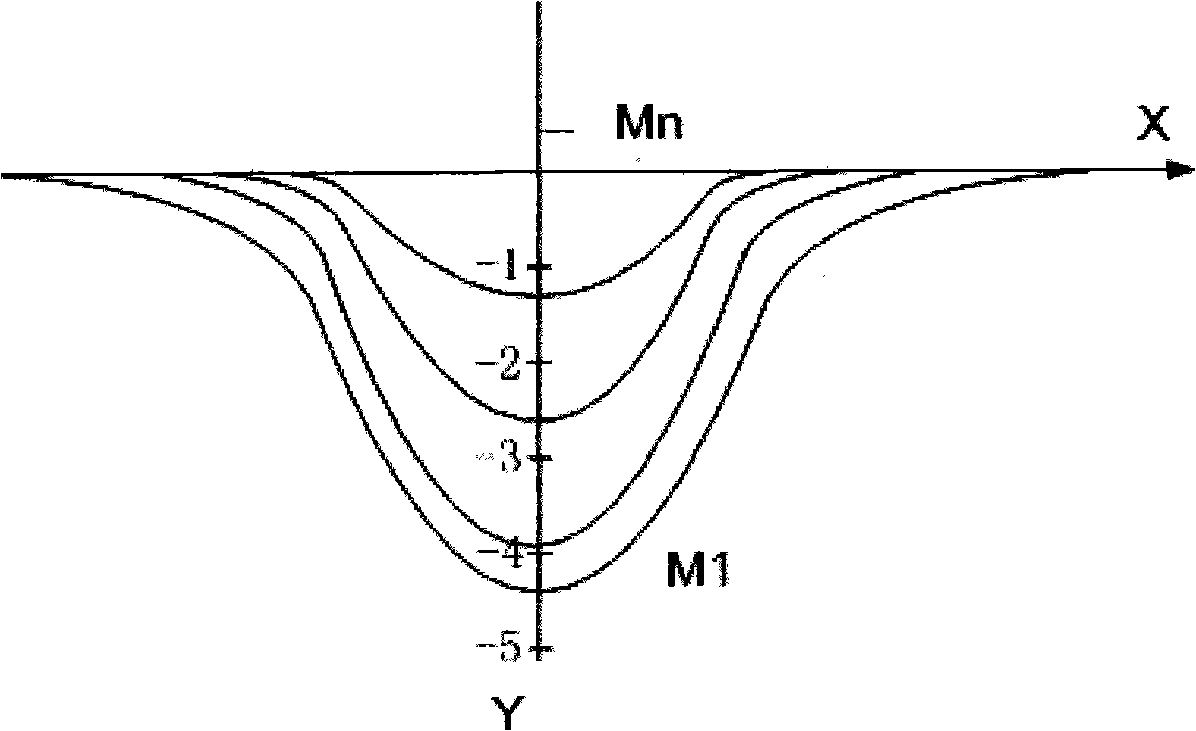

[0026] Figure 1~3 The relationship between the tension, pressure and stress distribution of the middle strip has been analyzed in detail in the background art, and will not be repeated here.

[0027] The coil-free micro-stress hot continuous rolling plate production equipment shown in Figure 4 consists of a heating furnace 1, a two-roll rough rolling unit 3, a four-roll rough rolling unit 4, a finishing rolling unit 5, a cooling section 6, and a coiler 7 are connected successively by roller tables to form a conventional hot continuous rolling unit. After the coiler 7, an extended roller table 11 with a length of 90 to 150 meters is assembled to meet the needs of medium and heavy plate production. The cutting mechanism 8 is assembled in the starting area of the extension roller table 11, and the cutting mechanism 8 is a flying shear or a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com