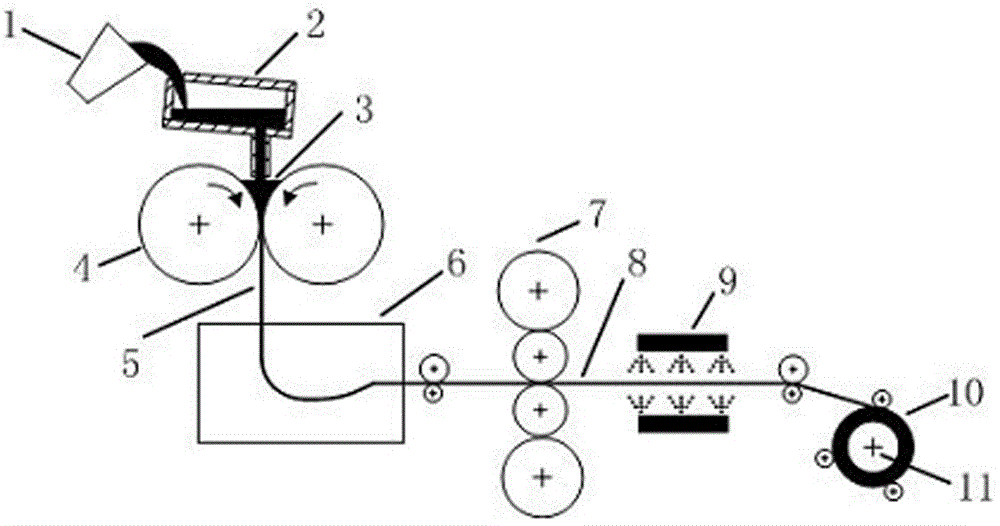

Method for improving volume fraction of acicular ferrite in twin-roll cast low-carbon thin strip steel

A technology of acicular ferrite and volume fraction, applied in the field of metallurgy, can solve the problems of poor performance of low-carbon thin strip steel and coarse structure of hot-rolled sheet, and achieve the effect of improving comprehensive performance, refining structure and shortening technical process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Smelting molten steel, the chemical composition contains C 0.03%, Si 0.2%, Mn 1.5%, Al 0.004%, V 0.02%, P 0.005%, S 0.001%, O 0.003%, N 0.01%, and the balance is Fe ;

[0026] Preheat the tundish to 1200°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1520°C, and solidify the molten steel through the gap of the casting rolls and export it out at a speed of Be 30m / min, obtain the casting belt that thickness is 2.5mm;

[0027] After the cast strip is exported to the casting roll, it is cooled to 900°C at 10°C / s, and then hot-rolled once to obtain a 2.0mm thick hot-rolled plate;

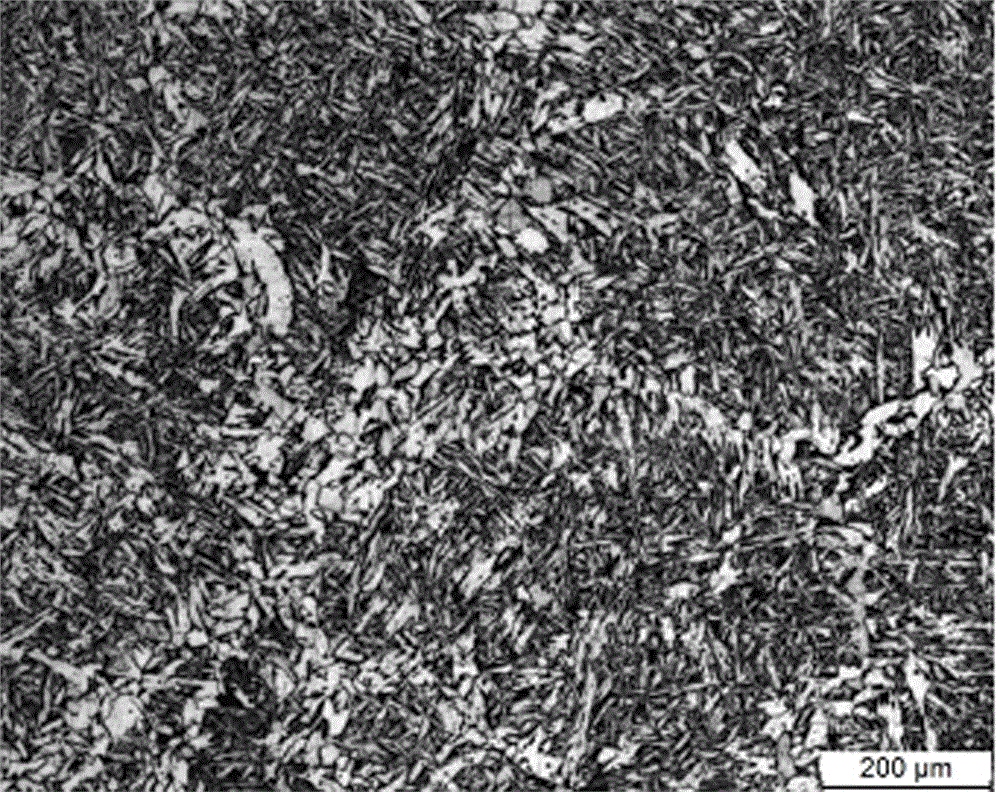

[0028] After the hot-rolled plate comes out of the hot-rolling mill, it is water-cooled to 550°C for crimping, and the water-cooling rate is 45°C / s to obtain low-carbon thin strip steel; the volume fraction of acicular ferrite in low-carbon thin strip steel is 90%, and the metallographic organize...

Embodiment 2

[0030] The molten steel for smelting contains 0.1% C, 0.3% Si, 1% Mn, 0.01% Al, 0.1% V, 0.003% P, 0.02% S, 0.005% O, 0.008% N, and the balance is Fe ;

[0031] Preheat the tundish to 1150°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1540°C, and solidify the molten steel through the gap of the casting rolls and export it out at a speed of Be 50m / min, obtain the casting belt that thickness is 2.0mm;

[0032] After the cast strip is exported to the casting roll, it is cooled to 1000°C at 12°C / s, and then hot-rolled once to obtain a 1.4mm thick hot-rolled plate;

[0033] After the hot-rolled plate leaves the hot-rolling mill, it is water-cooled to 570°C for crimping, and the water-cooling rate is 35°C / s to obtain a low-carbon thin strip steel; the volume fraction of acicular ferrite in the low-carbon thin strip steel is 63%, and its yield The strength is 450MPa, the tensile str...

Embodiment 3

[0035] Smelting molten steel, the chemical composition contains C 0.17%, Si 0.5%, Mn 1.3%, Al 0.002%, V 0.05%, P 0.01%, S 0.02%, O 0.008%, N 0.015%, and the balance is Fe ;

[0036] Preheat the tundish to 1130°C, pour the molten steel in the ladle into the twin-roll strip continuous casting equipment through the tundish, control the pouring temperature at 1520°C, and solidify the molten steel through the gap of the casting rolls and export it out at a speed of Be 40m / min, obtain the casting belt that thickness is 2.5mm;

[0037] After the cast strip is exported to the casting roll, it is cooled to 1050°C at 15°C / s, and hot rolling is started to obtain a hot-rolled plate with a thickness of 2.0mm;

[0038] After the hot-rolled plate leaves the hot-rolling mill, it is water-cooled to 650°C for crimping, and the water-cooling rate is 25°C / s to obtain a low-carbon thin strip steel; the volume fraction of acicular ferrite in the low-carbon thin strip steel is 95%, and the yield stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com