Preparation method of nitrogen-doped carbon quantum dot reinforced hBN nanofluid lubricant

A carbon quantum dot and nanofluid technology, applied in the field of lubrication, can solve the problems of poor lubricating performance, high size and surface energy of a single sheet, easy agglomeration and deposition of lubricating fluid, and achieve low cost, good dispersion stability, The effect of promoting energy saving, emission reduction and environmentally friendly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The main components and mass fraction of embodiment 1 are as follows:

[0026]

[0027]

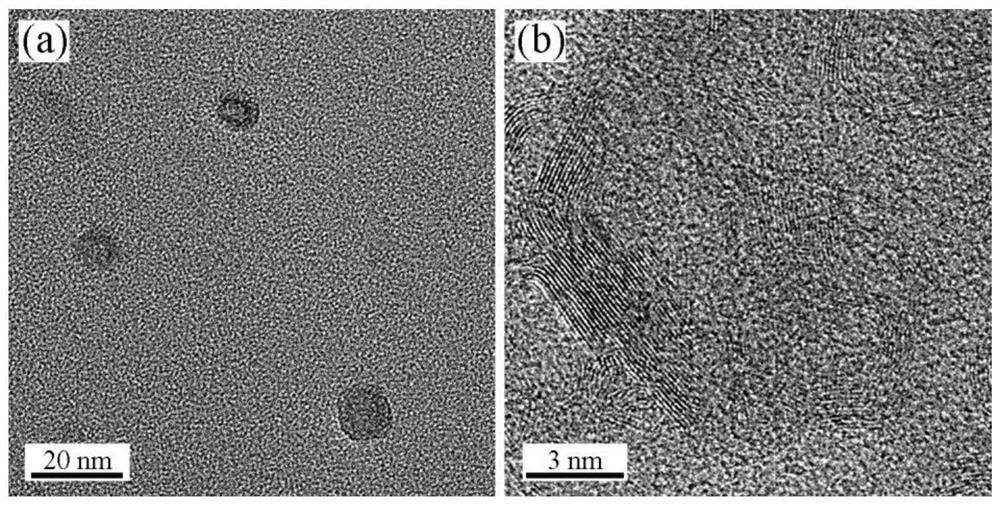

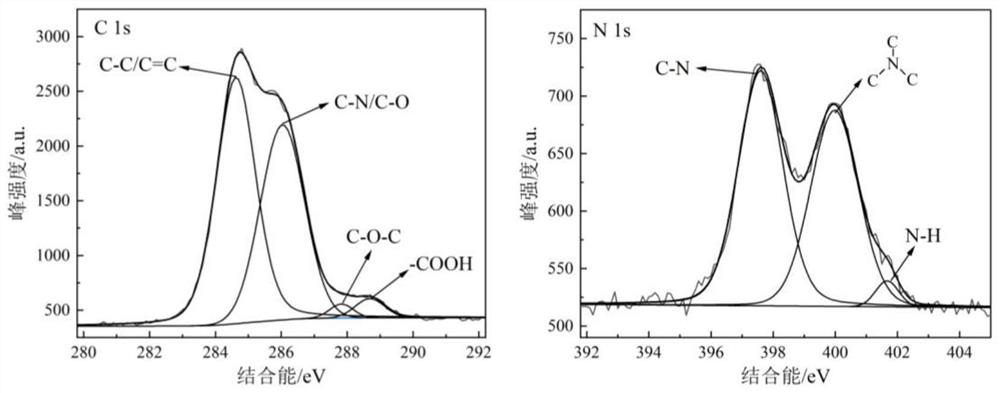

[0028] Add 3.0g of dopamine hydrochloride and peripheral dopamine into 100g of deionized water at a molar ratio of 1:1, then add 1.4g of sodium hydroxide, stir fully at 60°C and react for 1.5h, then add 4.3g of Concentrated nitric acid, mixed thoroughly, transferred to a high-pressure reactor, solvothermal reaction was carried out at 200 ° C for 12 hours, the product was washed with absolute ethanol and deionized water for several times, and then purified with a dialysis bag with a molecular weight cut-off of 3000 for 28 hours. The resulting solid matter was freeze-dried to obtain nitrogen-doped carbon quantum dots; then, according to the composition formula shown in the above table, 94.0g of deionized water was heated to 60°C, and nitrogen-doped carbon quantum dots were added in sequence at a speed of 800rpm. Point, hexagonal boron nitride, glycerol, triethanolamine, lauryl ...

Embodiment 2

[0031] The main components and mass fraction of embodiment 2 are as follows:

[0032] serial number component name Mass fraction / wt.% 1 Nitrogen-doped carbon quantum dots 0.4 2 Hexagonal boron nitride 1 3 Triethanolamine 2.1 Glycerol 3.5 4 Hexametaphosphate 0.8 5 Cocamidopropyl Betaine 1 6 Defoamer 0.1 7 Deionized water 90.1

[0033] Add 2.0g of dopamine hydrochloride to 100g of deionized water, then add 1.1g of sodium hydroxide, fully stir and react at 60°C for 1.5h, then add 3.5g of concentrated nitric acid to the above solution, mix well and transfer to high pressure reaction In the still, a solvothermal reaction was carried out at 220°C for 10 hours. The product was washed with absolute ethanol and deionized water for several times, and then purified with a dialysis bag with a molecular weight cut-off of 2000 for 30 hours. The obtained solid material was freeze-dried to obtain nitrogen-doped Heterog...

Embodiment 3

[0036] The main components and mass fraction of embodiment 3 are as follows:

[0037] serial number component name Mass fraction / wt.% 1 Nitrogen-doped carbon quantum dots 0.4 2 Hexagonal boron nitride 1.2 3 Triethanolamine 2 Glycerol 4 4 Hexametaphosphate 0.5 5 Lauryl dimethyl betaine 0.6 6 Cocamidopropyl Betaine 0.6 7 Defoamer 0.1 8 Deionized water 90.6

[0038] Add 4.0g of peripheral dopamine to 100g of deionized water, then add 2.0g of sodium hydroxide, fully stir and react at 60°C for 1.5h, then add 4.5g of concentrated nitric acid to the above solution, mix well and transfer to high pressure reaction In the kettle, a solvothermal reaction was carried out at 210°C for 12 hours. The product was washed with absolute ethanol and deionized water for several times and then purified with a dialysis bag with a molecular weight cut-off of 2500 for 25 hours. The obtained solid material was freeze-dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com