Method for the flying changing of working rolls in continuous casting and rolling installations and hot strip rolling mills using a hold-down roller

A technology for rolling equipment and roll replacement, applied in metal rolling stands, metal rolling, manufacturing tools, etc., can solve problems such as the impossibility of work roll replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

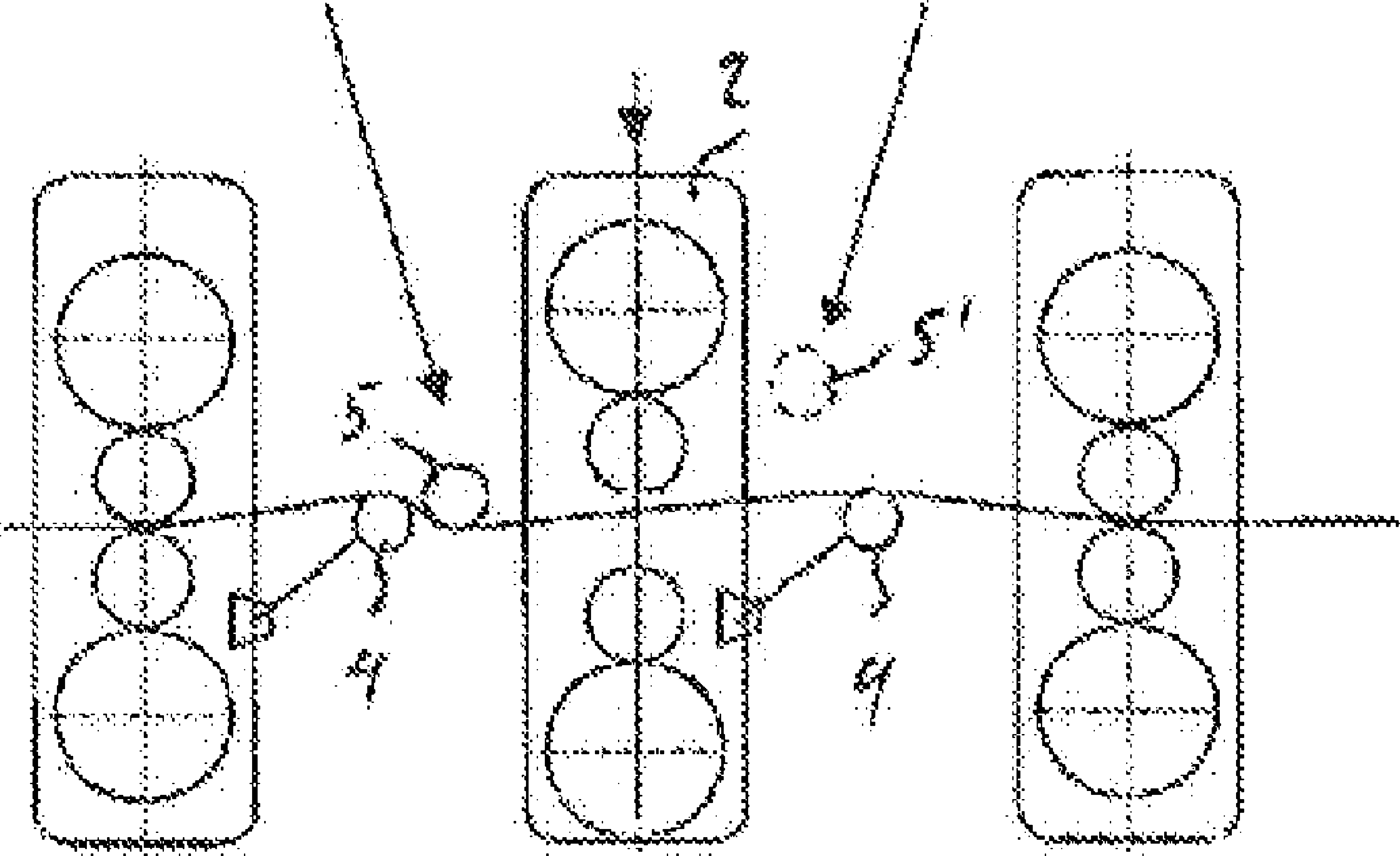

[0021] A conventional loop lifter 4 is located between the rolling stands 1 , 2 and 3 , via which the strip tension between the rolling stands can be adjusted. During a normal rolling process, as it is shown in FIG. 1 , neither the pressure roll 5 arranged before the rolling stand 2 nor, if present, the pressure roller 5 ′ arranged after the rolling stand is in contact with the hot rolling process. Band 6 is joined.

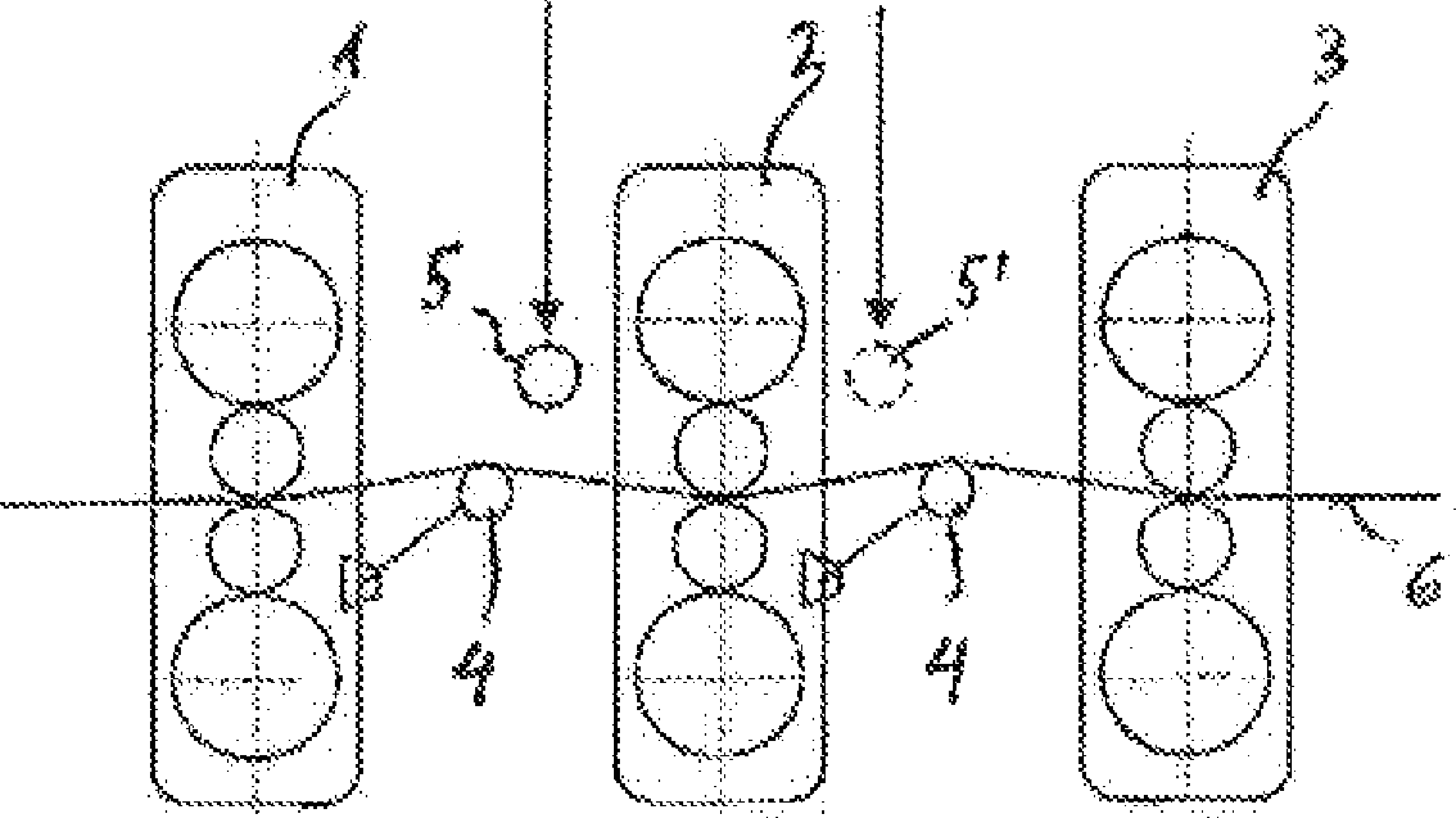

[0022] Now, for example, in order to change the work rolls in the middle rolling stand 2 , the rolls have to be approached, as shown in FIG. 2 .

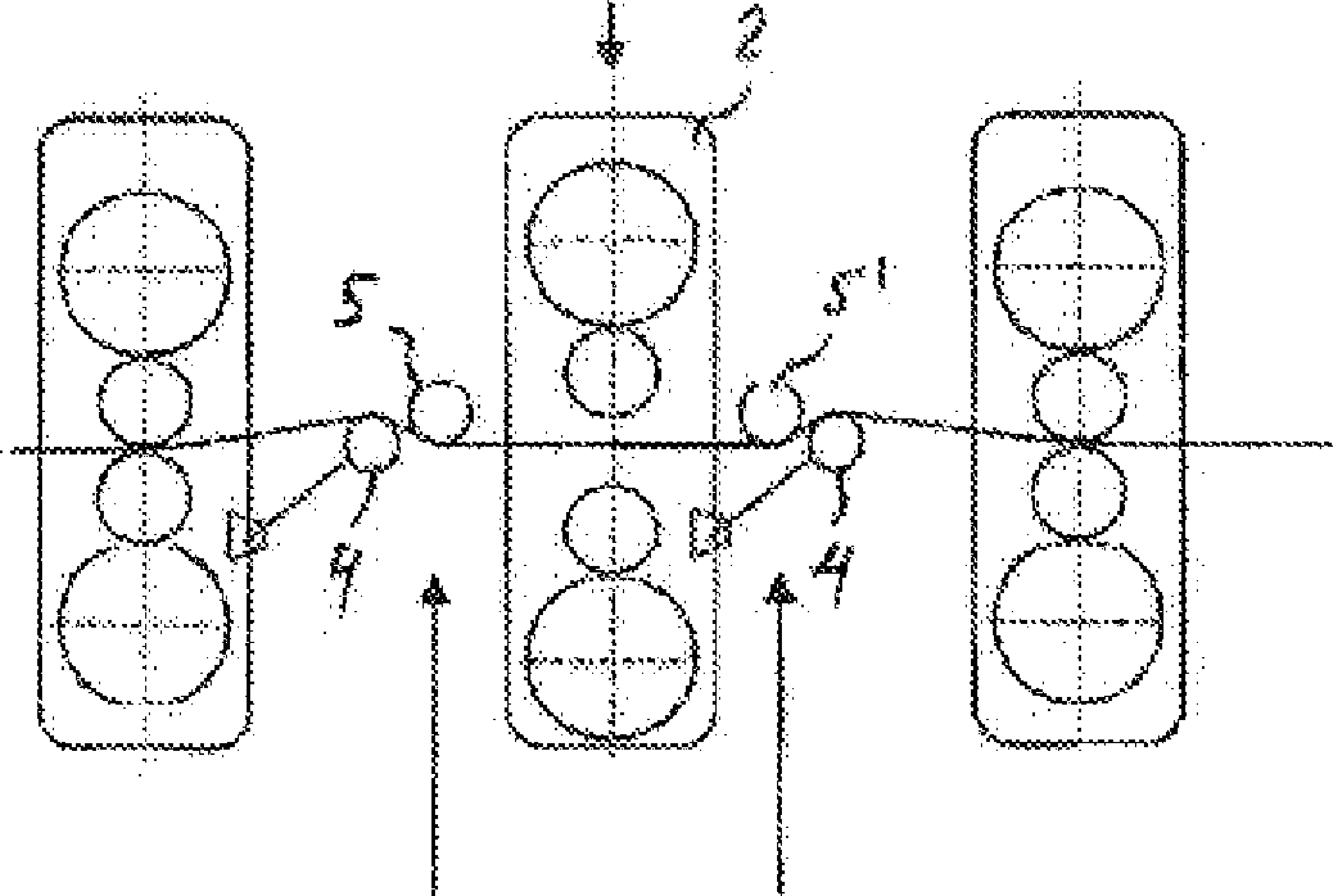

[0023] Since the hot strip is then no longer or not allowed to come into contact with the work rolls, at least the pressure roll 5 arranged in front of the roll stand 2 is activated, precisely together with the ring lifter 4 associated with it, so that The hot strip (without contacting the work rolls) can be guided through the open rolling stand with a corresponding strip tension.

[0024] The quick change of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com