Coarse filtration kettle

A coarse filter kettle and filter screen technology, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve problems such as low efficiency, and achieve the effects of improving production efficiency, reducing buffer time, and accelerating sedimentation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

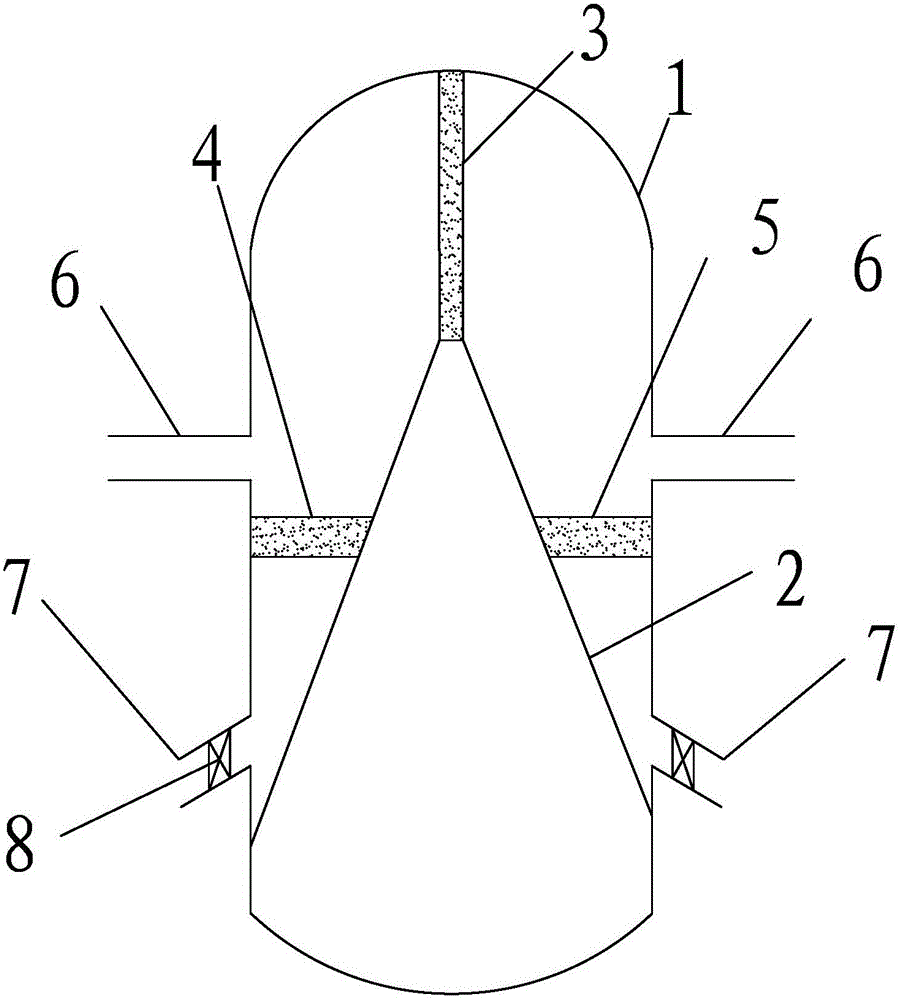

[0012] figure 1 As shown, a coarse filter kettle includes a filter kettle body 1. Two baffles 2 are arranged inside the body 1. One end of the two baffles 2 is connected to the inner side wall of the body 1, and the other end contacts to form a V V-shaped structure; the apex of the V-shaped structure is upward, and a first filter screen 3 is provided from the apex of the V-shaped structure to the upper surface inside the body 1; a second filter screen 4 and a third filter screen 5 are also provided, The second filter screen 4 and the third filter screen 5 are located on the same horizontal line, and one end of the second filter screen 4 and the third filter screen 5 is connected to one of the baffle plates 2, and the other end is connected to the inner side wall of the body 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com