Sheet shape control technology used in hot strip rolling of super-wide sheets

A technology of shape control and hot continuous rolling, applied in the direction of contour control, etc., can solve the problems of difficult control of shape quality of thin-gauge products, blind construction, difficulty in meeting the requirements of shape quality of thin-gauge products, and reach critical strip steel Reasonable effect of warpage calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

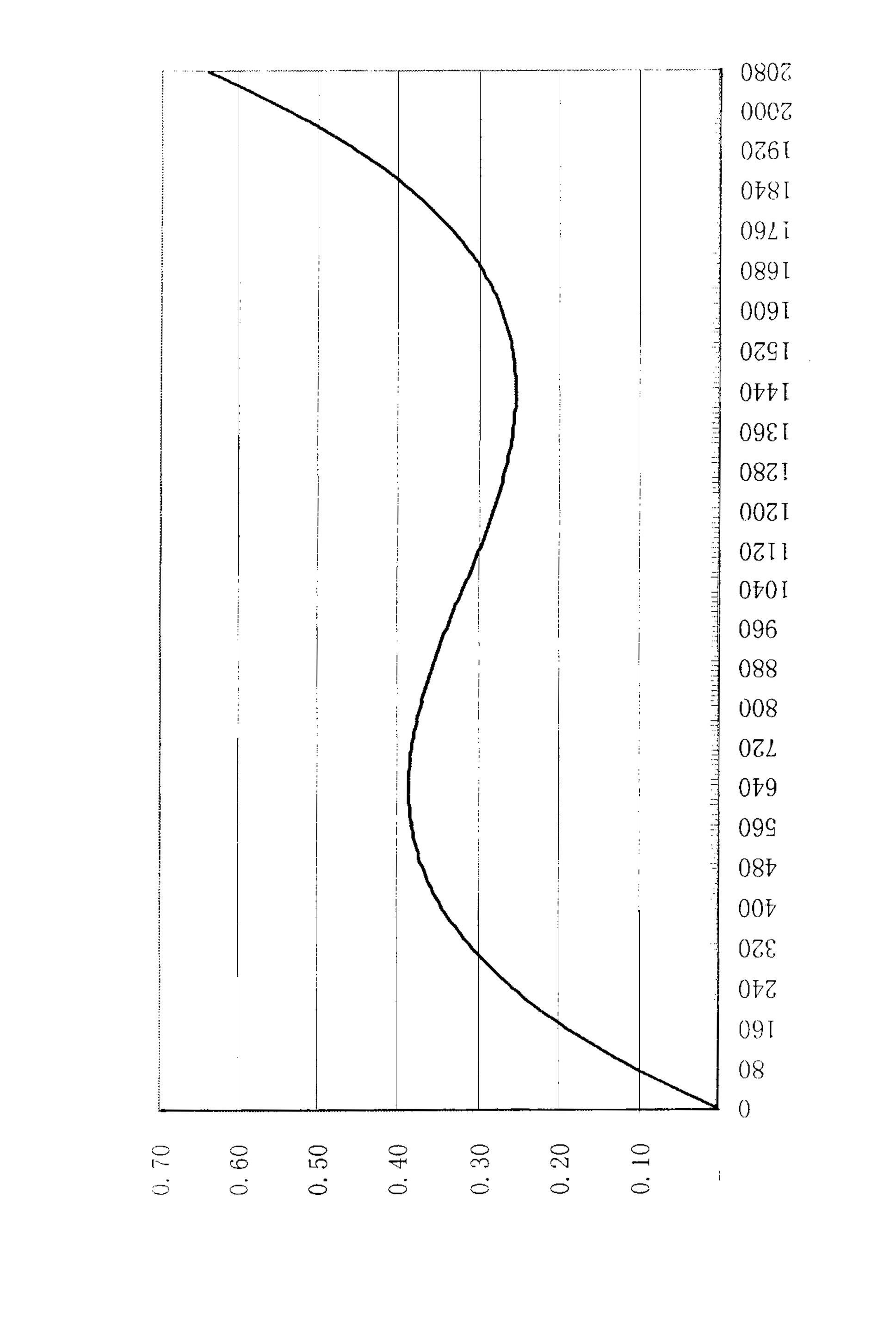

[0020] The AVC roll profile system is very critical to the production of hot continuous rolling. Optimize the design of the AVC roll profile to achieve continuous variable crown of the work roll; AVC roll profile curve design, the roll profile curve is S-shaped (such as figure 1 As shown, the ordinate is the change rate of the roll, and the abscissa is the temperature), and the upper and lower rolls are arranged upside down at 180°. Through the symmetrical movement of the two rolls in the opposite direction of the axial direction, continuously changing roll gap shapes with different convexities are obtained.

[0021] The AVC roll forming system has two features:

[0022] First, it has strong adaptability, flexible rolling plan arrangement, and the same set of roll types can be used to meet different specifications and different types of mixed rolling units,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com