Short-process production method and device for cold-rolled steel plate punched mesh

A production method and technology of cold-rolled steel plates, applied in the field of metallurgical processing, can solve the problems of high logistics costs and low production efficiency, and achieve the effects of reducing logistics transportation, improving production efficiency, and increasing product prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

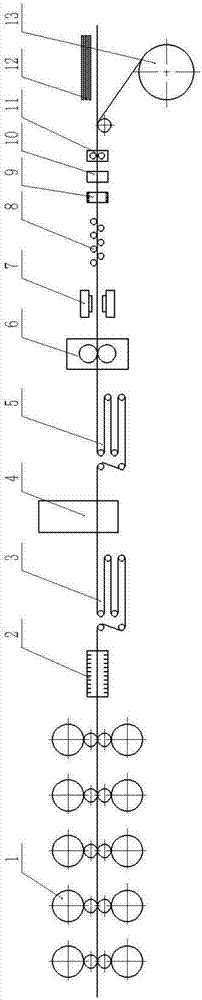

[0023] The raw material hot-rolled strip is processed by pre-rolling processes such as pickling, and then cold-rolled. The cold tandem rolling unit 1 is a five-stand cold tandem rolling unit, the strip width is 1250 mm, and the thickness of the finished product is 0.8 mm. mm, the rolling speed is 30m / s; after the strip is rolled to the required size, it enters the cleaning unit 2 for cleaning treatment to remove the remaining rolling oil and other surface stains on the surface of the cold-rolled strip, and the electrolytic cleaning tank adds 2% Alkaline degreasing agent, the electrolytic current is 2000A, and then the strip enters the inlet looper 3, and adapts to the change of rolling speed and annealing speed by adjusting the amount of the inlet looper; after the strip steel inlet and outlet looper 3 enters the continuous annealing unit 4, the The heat treatment of the step is divided into six stages, which are preheating section, heating section, soaking section, primary coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com