Strip steel hot rolling manufacturing technology

A production process and strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as affecting the quality of strip steel, and achieve the effect of improving quality, reducing the proportion of warping skin, and improving skin warping defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

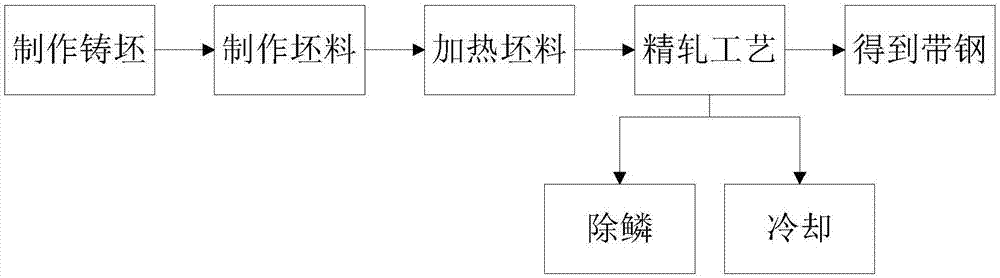

[0020] The core of this specific embodiment is to provide a strip steel hot rolling manufacturing process, which can improve the warping defect of the strip steel, improve the quality of the strip steel, and solve the current problems in this field.

[0021] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0022] The strip steel hot-rolling manufacturing process that this specific embodiment provides, mainly comprises steps:

[0023] Step 1, making a slab for casting strip steel, and setting the four sides of the slab along the length direction in a circular arc shape, that is, performing chamfering treatment, and making the four sides along the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com